Effective Strategies to Reduce Rolling Mill Roll Consumption

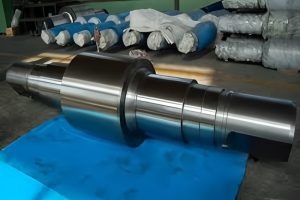

Rolls are in direct contact with the strip during rolling and serve as essential tools in hot rolling production. Reducing roll consumption can effectively lower

Rolls are in direct contact with the strip during rolling and serve as essential tools in hot rolling production. Reducing roll consumption can effectively lower

Keywords: Bar rolling Description: High-speed bar rolling is an advanced steel production process that yields bars with enhanced mechanical properties and superior corrosion resistance. This technology

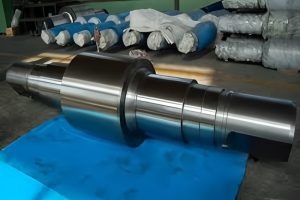

Independently Developed New Mill Roll Materials Successfully Developed Special Rolls for Finishing Mills in Wire Rod (Plain Wire) Production For finishing rolls in wire rod

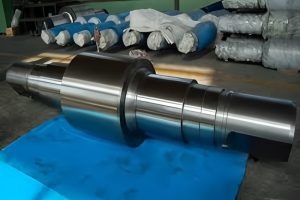

Pioneering Rapid Casting for Conventional Rolls HANI roll manufacturer completed the pouring of 8 rolls (Ø300–Ø400 mm) from a single 5-ton ladle in just 4

Description: Roll surface defects such as chatter marks, roll marks, scoring, cracks, and spalling can adversely affect product surface quality. Investigating the causes and solutions for

How to Select the Right Rolling Mill Roll Material Description: This article discusses the working conditions of both cold and hot rolling mill rolls, and provides

Solving Oxide Film Peeling on Rolling Mill Rolls Description: Peeling of the oxide film on rolling mill rolls significantly impacts strip surface quality. Effective control of

Considering the complex cross-sections of large and medium section steels and the varying performance requirements for rolls at different stands, this article identifies key factors

Formation Mechanisms and Control Strategies for Red Scale and Copper Brittle Defects in Hot-Rolled Strip Red scale and copper brittle defects are common quality issues

All contents of this website are copyrighted by HANI GROUP and may not be reproduced in any form without permission.

We would be happy to help and advise if you have any questions or inquiries.