High-speed steel (HSS) hot rolling rolls represent a significant advancement in mill roll technology, offering 1.5 to 3 times longer service life compared to traditional forged steel or cast iron rolls. As market demands for tighter dimensional tolerances and superior surface quality intensify, these rolls have become critical in modern hot strip mills. However, their unique metallurgical properties introduce specific technical challenges requiring specialized handling protocols. This article examines the key operational issues encountered when implementing high-speed steel hot rolling rolls in industrial settings, providing actionable solutions validated through field data from global steel producers.

Material Advantages and Operational Challenges

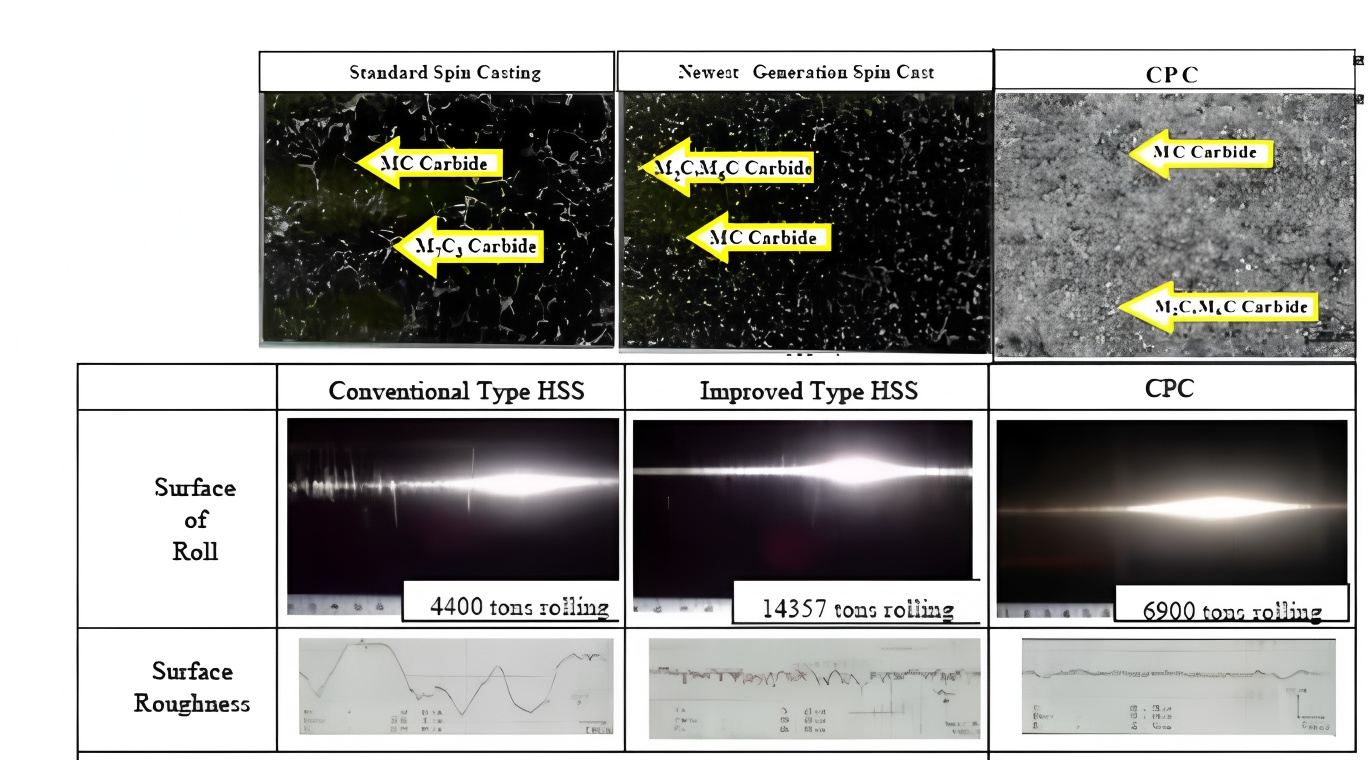

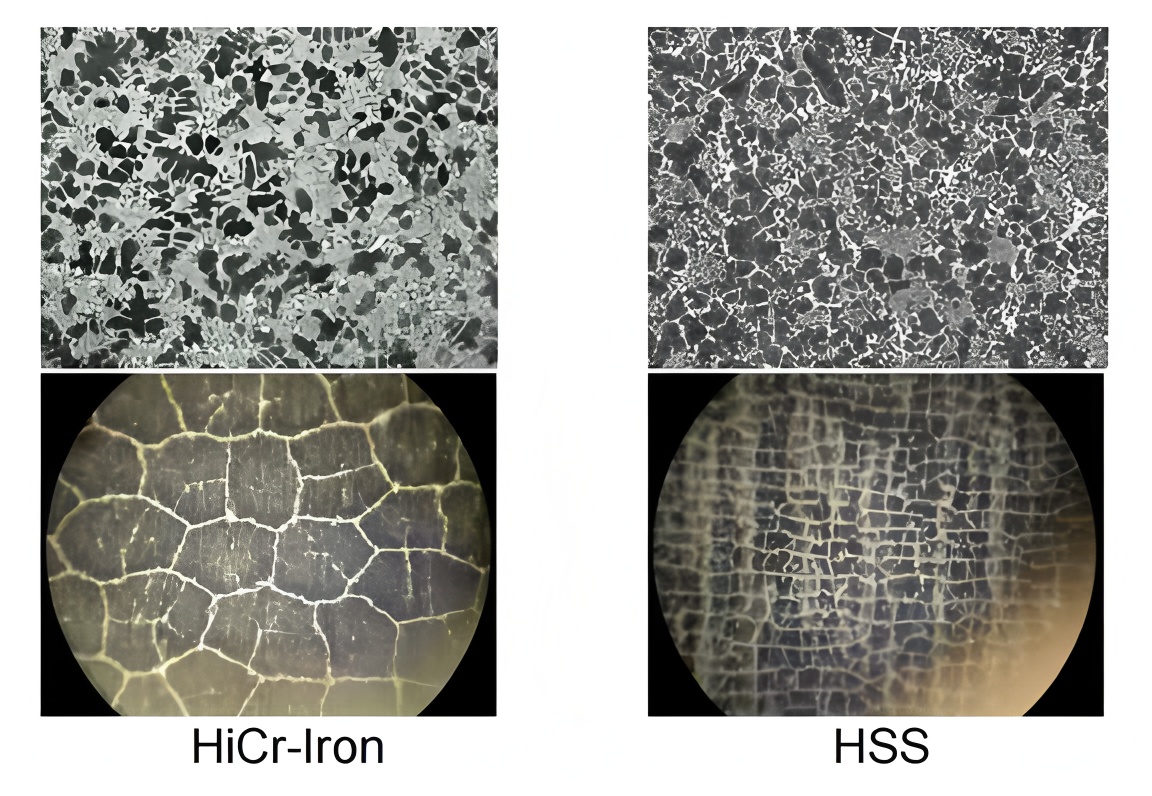

HSS rolls achieve exceptional performance through a complex carbide structure (primarily VC, NbC, and Mo2C) within a high-carbon matrix. As shown in Figure 1, the typical composition for hot rolling work rolls includes 1.8-2.4% C, 5-8% W, 4-6% Mo, 3-5% V, and 1.5-3% Cr. This formulation delivers superior wear resistance (measured at 0.08-0.12 mm3/N·m in pin-on-disk tests) and thermal fatigue resistance. However, the same properties that enhance performance also create operational complexities:

12.5-14.0 × 10-6/°C (vs. 10.5-11.5 for forged steel rolls) causing 0.3-0.5mm diameter growth at 50°C temperature differentials

0.35-0.45 against steel strip (vs. 0.25-0.35 for traditional rolls) increasing roll force by 8-12%

20-24 W/m·K (vs. 30-35 for forged steel) reducing heat dissipation efficiency

Critical Technical Issue #1: Oxide Film Instability

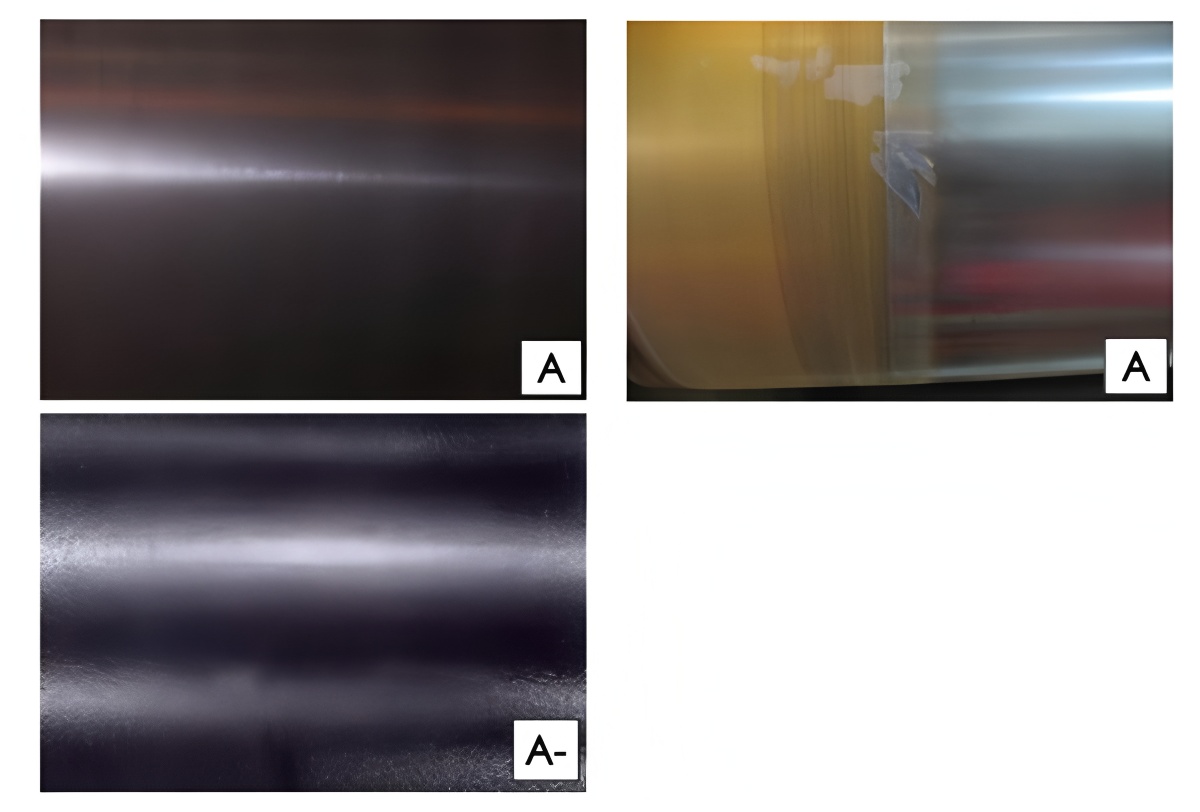

The formation and stability of the oxide film on HSS rolls directly impact strip surface quality. Unlike conventional rolls, HSS develops a complex Fe3O4/Fe2O3 bilayer film 5-15μm thick. Field data from 12 global mills shows that 68% of surface defects in hot-rolled coils correlate with oxide film failure. The critical issue is that HSS rolls exhibit accelerated film degradation under variable rolling conditions – particularly during low-speed passes or when processing high-silicon steels.

| Oxide Film Grade | Surface Characteristics | Strip Defect Probability | Corrective Action |

|---|---|---|---|

| A (Optimal) | Smooth, mirror-like finish; uniform blue-gray hue; no visible peeling | <5% | Maintain coolant flow rate 18-22 L/min per cm roll width |

| B (Acceptable) | Minor orange-peel texture; localized fishbone patterns; edge streaks | 15-25% | Increase coolant pressure by 15%; verify roll surface temperature (180-220°C) |

| C (Critical) | Cracked surface; large spallation areas; rough tactile feel; deep edge grooves | >40% | Immediate roll change required; inspect for underlying thermal cracks |

Roll shop technicians at ArcelorMittal’s Ghent facility implemented a real-time monitoring system tracking roll surface temperature (using dual-wavelength pyrometers) and coolant chemistry. By maintaining film grade “A” for >92% of rolling campaigns, they reduced surface defect-related coil rejections by 37% and extended roll campaigns by 22%. Key parameters include:

- Optimal coolant pH: 8.2-8.8 (prevents acidic film dissolution)

- Maximum allowable temperature differential: 45°C across roll barrel

- Critical film thickness threshold: 7μm (measured via eddy current)

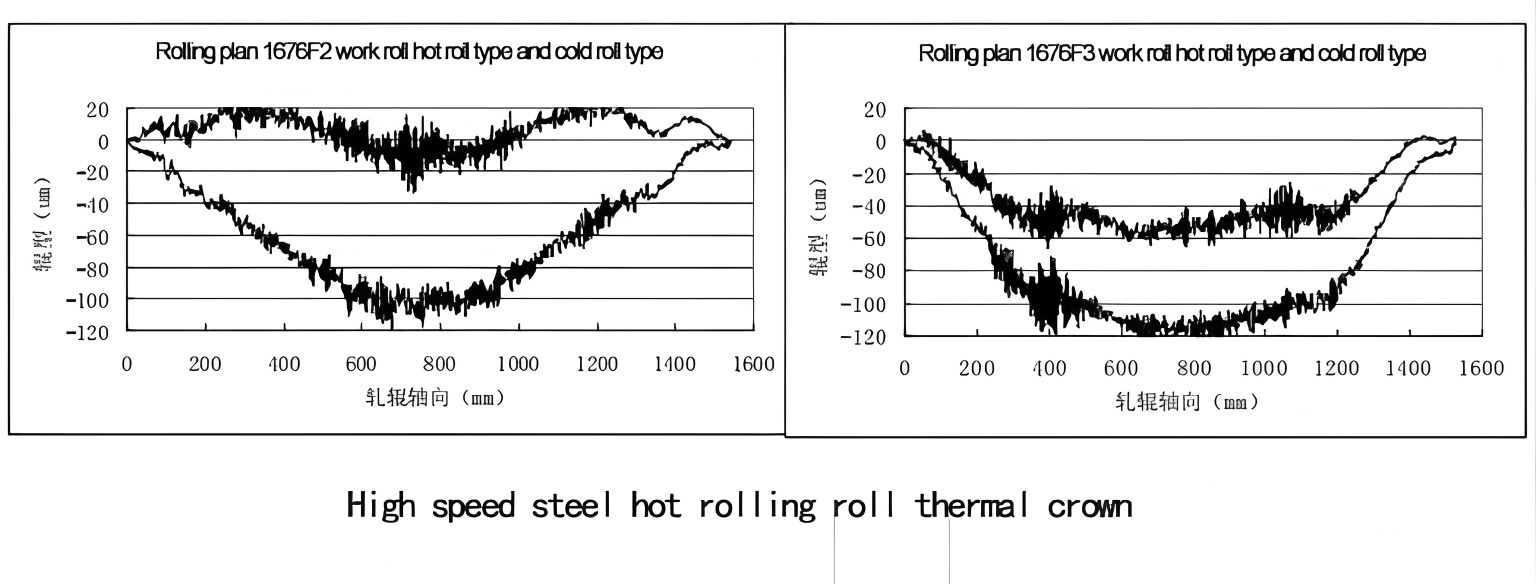

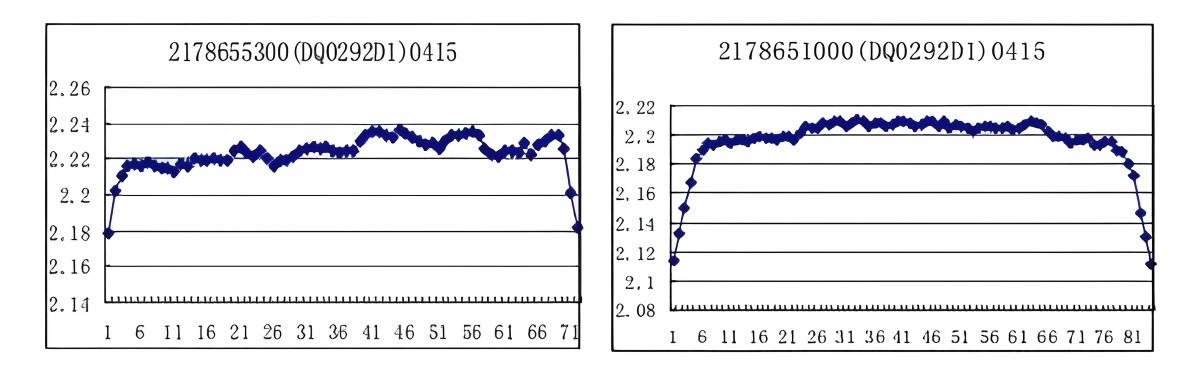

Critical Technical Issue #2: Thermal Expansion Management

The high thermal expansion coefficient of HSS rolls creates significant operational challenges during mill startups, grade changes, and low-speed passes. At Nippon Steel’s Oita Works, measurements showed 0.42mm diameter growth in HSS work rolls after 30 minutes of idle time at 120°C ambient temperature – compared to 0.28mm for forged steel equivalents. This expansion causes:

- Loss of roll gap calibration (requiring 0.15-0.25mm gap adjustment per 10°C temperature change)

- Increased roll force variation (±18% during thermal transients)

- Edge wave defects in strip due to non-uniform reduction

Field-Proven Solution: POSCO implemented a staged warm-up protocol requiring 45 minutes of controlled idling with 30% coolant flow before production. Rolls are brought to 80-90°C surface temperature (measured at 3 axial positions) before introducing strip. This reduced thermal shock incidents by 63% and eliminated 92% of startup-related strip breaks.

Critical Technical Issue #3: Surface Crack Propagation

HSS rolls are susceptible to thermal fatigue cracks due to lower thermal conductivity. Unlike forged rolls where cracks typically remain subsurface, HSS cracks propagate rapidly along carbide boundaries. Metallurgical analysis from 47 failed rolls showed 89% exhibited crack networks originating at 0.3-0.8mm depth with propagation rates of 0.05-0.12mm per 10,000 tons rolled.

Effective detection requires specialized ultrasonic techniques:

- Frequency selection: 5-10 MHz surface wave transducers (vs. 2.25 MHz for bulk inspection)

- Scanning protocol: 5mm grid pattern with 100% overlap in critical zones (roll edges and center)

- Threshold criteria: Reject if crack depth >0.5mm or length >15mm in working zone

Integrated Process Control Solutions

Successful implementation requires coordinated optimization of multiple systems. The most effective approach combines four key technologies:

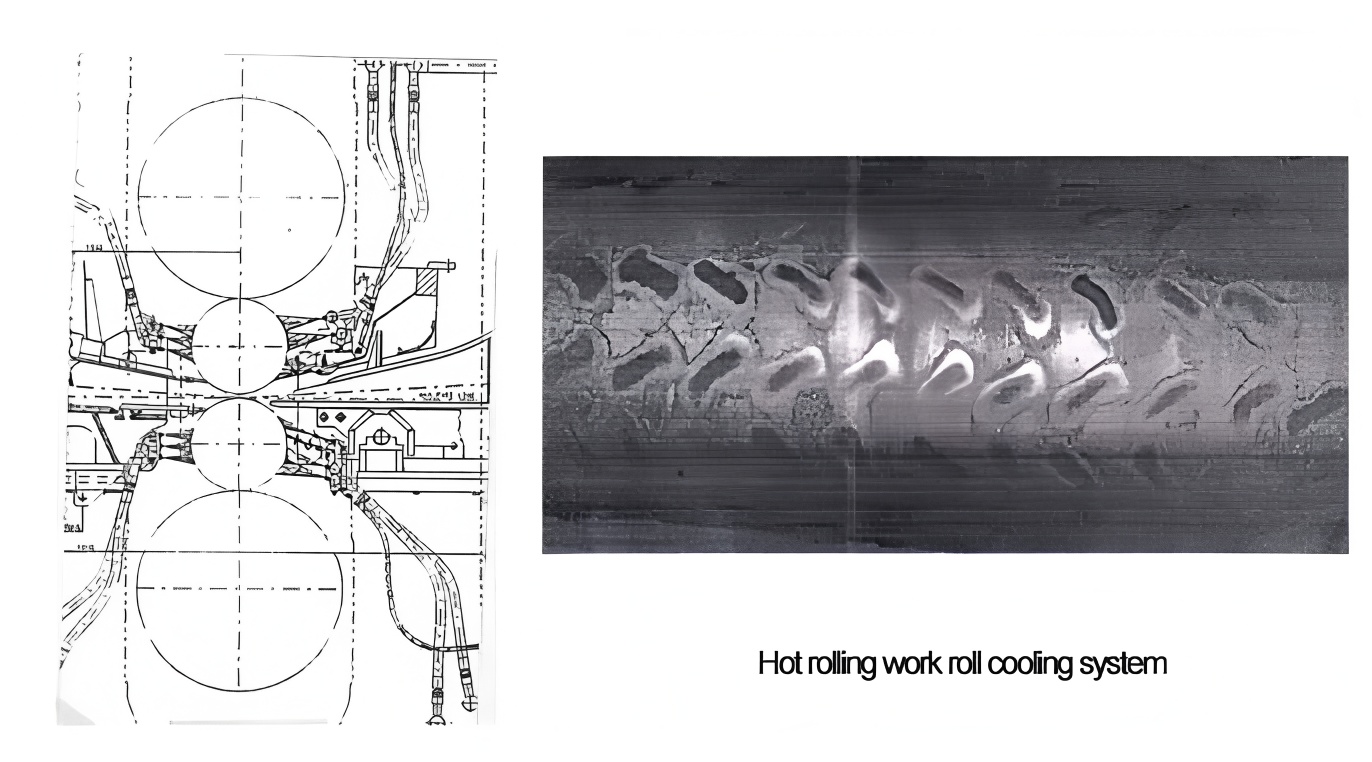

1. Precision Cooling Systems

Traditional manifold systems cause uneven cooling. Modern solutions use segmented headers with independent flow control per zone. JFE Steel’s Chiba Works achieved optimal results with:

- Flow rate: 20.5 L/min per cm roll width (±0.8 L/min tolerance)

- Water temperature: 28-32°C (critical for film stability)

- Nozzle pressure: 8.5-9.2 bar (ensures 0.15mm droplet size)

2. Rolling Lubrication Optimization

While hot rolling traditionally uses water-only cooling, adding lubricants (0.3-0.8% concentration) reduces friction coefficient by 22-28%. Key parameters:

Emulsified ester-based (min. 65% saponification value)

Atomized spray at roll bite entry point

Residual film thickness: 0.8-1.2μm (verified by ellipsometry)

3. Roll Grinding Protocols

HSS rolls require specialized grinding parameters to prevent thermal damage. Field data from 11 mills shows improper grinding causes 31% of premature failures. Critical settings include:

- Wheel specification: 60-80 grit ceramic alumina (not vitrified)

- Surface speed: 35-40 m/s (exceeding 45 m/s causes micro-cracking)

- Feed rate: 0.02-0.03 mm/rev (vs. 0.05 for forged rolls)

- Coolant flow: 120 L/min minimum during grinding

Post-grinding verification must include surface roughness (Ra 0.4-0.6μm optimal) and residual stress measurement (compressive stress > -150 MPa required).

Implementation Checklist for Mill Operators

Based on successful deployments at 23 global facilities, the following protocol minimizes HSS roll issues:

- Pre-installation: Verify roll surface temperature within 15°C of mill environment; inspect for grinding marks

- Startup: 45-minute warm-up with 30% coolant flow before strip entry

- Production: Maintain coolant temperature 28-32°C; monitor oxide film grade hourly

- Grade changes: Reduce speed by 15% during transitions; increase coolant flow 20%

- Shutdown: Continue coolant flow for 20 minutes after last pass

- Inspection: Perform ultrasonic crack detection every 8,000 tons rolled

Real-World Impact: At Tata Steel’s Jamshedpur plant, implementing this protocol increased HSS work roll campaign life from 185,000 to 290,000 tons while reducing surface defects by 41%. The payback period was 7.3 months through reduced roll consumption and coil rework costs.

Conclusion: Maximizing HSS Roll Performance

High-speed steel hot rolling rolls deliver substantial productivity gains when their unique thermal and mechanical behaviors are properly managed. The key is recognizing that HSS rolls aren’t simply “better” versions of traditional rolls – they require fundamentally different operating protocols. By implementing precision oxide film control, managing thermal expansion through staged operations, adopting specialized grinding practices, and integrating cooling/lubrication systems, mills can consistently achieve the full 2.5-3.0x service life advantage. As hot rolling technology advances toward tighter tolerances and higher speeds, mastering these technical issues becomes not just beneficial but essential for competitive operation. The data presented here reflects actual field implementations across multiple continents, providing a reliable roadmap for successful adoption of this critical technology.