High-speed steel (HSS) rolls have emerged as a transformative solution in modern steel rolling operations, offering unparalleled performance in demanding hot and cold rolling environments. Engineered with advanced metallurgical compositions and precision manufacturing techniques, HSS rolls deliver exceptional hardness, red hardness, and wear resistance—critical attributes for maximizing mill productivity, product quality, and cost efficiency.

Why High-Speed Steel Rolls? Core Advantages

Unlike conventional high-chromium cast iron or forged alloy steel rolls, high-speed steel rolls are formulated with elevated carbon (typically >1.5%) and a dense matrix of hard carbides (10–20% by volume). These carbides—primarily MC (e.g., VC, NbC) and M₂C (e.g., Mo₂C, W₂C)—are uniformly dispersed throughout the working layer, ensuring consistent wear behavior across the roll surface.

Key performance metrics of HSS rolls include:

- Surface Hardness: 80–90 HSD (Hardness Shore D), with variation ≤2 HSD across the barrel

- Red Hardness: Maintains >85% of room-temperature hardness at 600°C

- Hardenability: Near-uniform hardness from surface to core of working layer

- Core Material: High-strength alloyed ductile iron (e.g., Ni-Hard IV or modified ADI) for neck toughness and fatigue resistance

- Alloy Content: Total alloying elements (Cr, Mo, W, V, Nb) ≥16%

Real-World Performance: Case Studies from Leading Steel Plants

Industrial adoption of HSS rolls has yielded measurable gains in roll life, throughput, and operational economics. Below are verified results from three major steel producers:

| Steel Plant | Application | Roll Type Compared | Avg. Rolling Volume per Roll | Roll Consumption (kg/t) |

|---|---|---|---|---|

| Plant A | Hot Strip Finishing Mill | High-Chromium Cast Iron | 2.2–3.5× higher | 0.7 → <0.4 |

| Plant B | Hot Strip Finishing Stands | High-Chromium Cast Iron | 5,500 t vs. 2,380 t | Not reported (↓ ~57% usage) |

| Plant C | Rebar Finishing Mill (Slit Rolling) | Conventional Alloy Cast Iron | Groove life ↑ 300–400% | Significant reduction in labor & regrind costs |

These results underscore that despite a higher initial investment, HSS rolls deliver superior total cost of ownership due to extended service intervals, reduced downtime, and improved surface finish on rolled products—especially critical for cold rolling mill rolls and hot rolling mill rolls in high-precision applications.

Critical Operational Considerations for HSS Roll Success

While HSS rolls offer outstanding performance, their effective deployment requires strict adherence to process controls. Mismanagement can lead to premature failure, negating their economic benefits.

1. Temperature Control & Cooling Strategy

HSS rolls exhibit lower thermal conductivity than traditional materials, making them susceptible to thermal gradients. Uncontrolled heating can cause:

- Thermal cracking and spalling

- Unstable oxide film formation

- Roll bursting under extreme thermal shock

Best Practices:

- Maintain roll surface temperature <60–65°C during operation

- Use flat-jet nozzles (not conical) with optimized water distribution: 75% to strip exit side, central flow = 2× end flow

- Water pressure: 0.5–0.7 MPa; nozzle angle: 20–30° against roll rotation

- Pre-cool grooves before contact with hot billet (especially in slit rolling of ribbed bars)

Oxide film thickness must be carefully balanced—too thick (>5 µm) leads to brittle spallation; too thin (<1 µm) increases friction and wear. Ideal range: 2–4 µm.

2. Load Management

HSS rolls have a higher coefficient of friction (~0.12–0.15 vs. ~0.08–0.10 for Cr-iron), increasing rolling load by 10–20%. Excessive load damages the protective oxide film.

Solutions:

- Redistribute reduction ratios—lighter passes in finishing stands

- Ensure uniform slab entry thickness from roughing mill

- Avoid sudden load spikes during threading or cobbles

3. Lubrication Optimization

Effective lubrication is non-negotiable for HSS roll longevity. Modern mills have shifted from manual grease (e.g., 3# lithium complex) to automated centralized systems delivering oil-in-water emulsions.

Benefits include:

- Friction coefficient reduction by 30–40%

- Lower roll surface temperature (↓15–25°C)

- Stabilized oxide film and reduced thermal stress

- Improved surface finish on cold rolled steel and hot-rolled strip

4. Handling Post-Pile-Up Incidents

In rebar rolling mills using slit pass designs, cobble events are common. If red-hot steel jams in an HSS groove:

- Do NOT shut off cooling water immediately

- Continue cooling until trapped steel turns black (≈500°C)

- Rapid quenching of hot zones causes microcracks that propagate during subsequent rolling

Applications Across Rolling Mill Types

HSS rolls are now standard in:

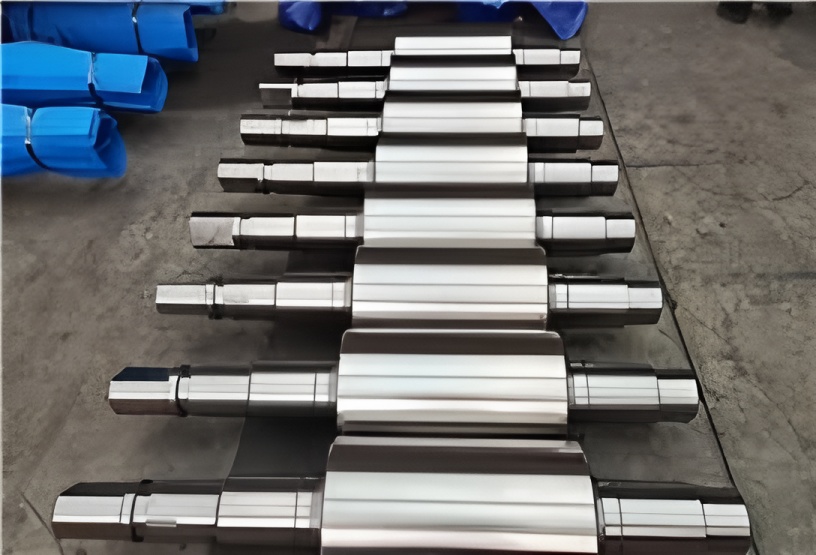

- Hot Strip Mills: Finishing stands F4–F7 for improved surface quality and reduced changeouts

- Bar & Rod Mills: Finishing and pre-finishing stands for rebars, wire rods, and merchant bars

- Section Mills: Universal beam and rail rolling where edge wear is critical

- Cold Rolling Mills: Increasingly adopted in 4Hi and 6Hi mills for stainless and specialty alloys requiring high surface fidelity

For tungsten carbide rolls, HSS offers a more cost-effective alternative in medium-to-high wear scenarios, though WC remains preferred for ultra-fine wire or foil applications.

Selecting the Right HSS Roll Supplier

When sourcing mill roll manufacturers for HSS products, verify:

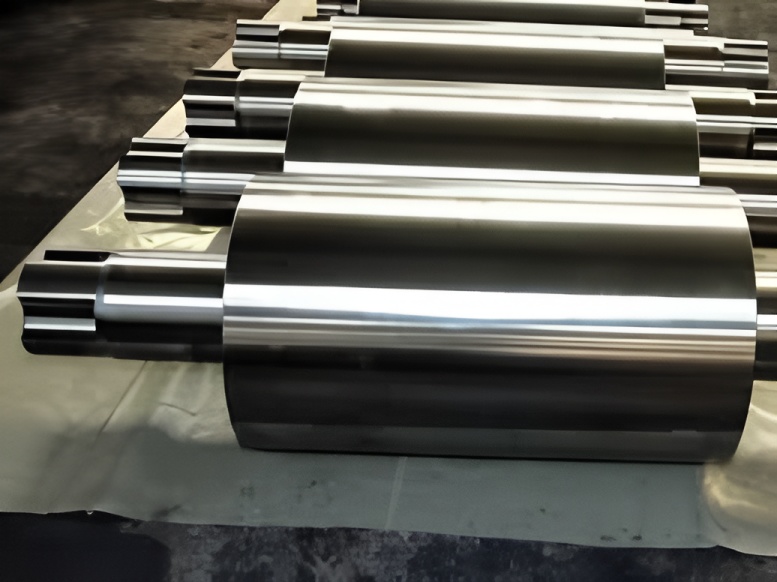

- Centrifugal casting or continuous pouring process capability

- Heat treatment protocols (tempering ≥3 cycles to relieve residual stress)

- Non-destructive testing (ultrasonic + magnetic particle inspection)

- Chemical composition certification (ASTM A835 or equivalent)

- Field support for roll grinding, assembly, and troubleshooting

Leading global suppliers include United Rolls, Deem Roll Tech Ltd., and specialized foundries in India, China, and Europe. Always request trial data from similar mill configurations before full-scale adoption.

Conclusion: The Future Is High-Speed

As steelmakers push toward thinner gauges, higher speeds, and cleaner surfaces, high-speed steel rolls have transitioned from premium option to operational necessity. Their synergy with modern rolling mill roll design, advanced cooling, and lubrication systems unlocks step-change improvements in efficiency. For mills evaluating types of rolls used in rolling mills, HSS represents the optimal balance of performance, durability, and lifecycle cost—particularly when paired with rigorous process discipline.

Whether you operate a hot rolling mill, cold rolling mill, or specialty section mill, integrating HSS rolls—supported by data-driven maintenance—is a strategic move toward sustainable competitiveness in today’s steel market.