High-speed steel (HSS) rolls represent a critical advancement in rolling mill technology, delivering unprecedented performance in demanding hot and cold rolling applications. As metallurgical demands intensify across steel production facilities, understanding the precise characteristics and manufacturing methodologies of HSS rolls becomes essential for mill operators seeking to optimize productivity and reduce operational costs. This comprehensive analysis examines the scientific principles behind HSS roll superiority, validated by industrial data from leading mill roll manufacturers worldwide.

Defining High-Speed Steel Rolls: Material Science Fundamentals

HSS rolls differ fundamentally from conventional rolling mill roll material options like high-chromium iron or indefinite chilled iron. Their composition—typically containing 1.5-2.5% carbon, 3-12% tungsten, 3-8% molybdenum, 4-10% vanadium, and 3-5% chromium—creates a microstructure dominated by ultra-hard primary carbides. Unlike traditional rolls where coarse Fe3C (1300 HV) or M7C3 (2500 HV) carbides form during solidification, HSS rolls develop MC-type carbides (primarily VC at 3000 HV), M6C (2000 HV), and secondary M7C3. This carbide architecture, verified through electron microscopy studies at institutions like Nippon Steel’s Research Laboratories, directly enables the exceptional wear resistance that defines modern HSS performance.

Seven Critical Characteristics of HSS Rolls

Unmatched Carbide Hardness (3000 HV)

While high-chromium iron rolls rely on M7C3 carbides (2500 HV) and indefinite chilled iron uses Fe3C (1300 HV), HSS rolls incorporate vanadium carbides (VC) reaching 3000 HV. Japanese metallurgical studies confirm that increasing vanadium content beyond 5% promotes granular VC formation instead of brittle skeletal M6C structures. This microstructural refinement reduces spalling risk while enhancing wear resistance—particularly crucial for cold rolling mill rolls where surface finish requirements are stringent.

Exceptional Thermal Stability at 600°C

HSS rolls maintain approximately 500 HV hardness at 600°C, a critical advantage over conventional materials which lose 30-40% hardness at this temperature. The synergistic effect of tungsten, molybdenum, and cobalt creates secondary hardening through fine M2C carbide precipitation during tempering. Data from POSCO’s Gwangyang mill demonstrates that HSS work rolls in finishing stands (F1-F4) operate continuously at 550-620°C surface temperatures without significant softening.

Self-Forming Oxide Film Mechanism

During rolling, HSS rolls develop a continuous Fe2O3-rich oxide layer 2-5μm thick. This film reduces the coefficient of friction from 0.35 to 0.15 compared to high-chromium rolls, directly improving strip surface quality. At ArcelorMittal’s Ghent facility, this characteristic reduced surface defects by 62% in automotive-grade cold rolled steel production. The rapid formation (within 200 tons of rolling) also minimizes initial wear, extending roll life by 1.8× compared to tungsten carbide composite rolls in similar applications.

Uniform Hardness Profile Through Depth

HSS rolls exhibit exceptional hardenability, with hardness variation of less than 3 HS within 50mm depth from the surface. This consistency is verified through cross-sectional hardness testing per ASTM E18 standards. In contrast, forged steel rolls typically show 8-12 HS drop over the same depth. This uniformity ensures consistent wear resistance throughout the working layer—critical for hot rolling mill rolls subjected to thermal cycling.

Optimized Toughness Balance

While maintaining high hardness (65-72 HSD), HSS rolls achieve Charpy impact values of 8-12 J/cm² at -20°C—significantly better than high-chromium iron rolls (4-6 J/cm²) and comparable to semi-steel rolls. This balance prevents catastrophic fracture during mill incidents like steel breakouts. Recent developments incorporating niobium (0.3-0.8%) further enhance fracture toughness by promoting (V,Mo,Nb)C composite carbides that resist crack propagation.

Superior Thermal Crack Resistance

HSS rolls demonstrate 40-60% fewer thermal cracks than high-chromium iron rolls after 5,000 tons of rolling in hot strip mill finishing stands. The fine carbide network effectively arrests microcrack propagation. At Tata Steel’s Jamshedpur plant, HSS work rolls required only 0.3mm regrinding after thermal incidents versus 0.8mm for conventional rolls—translating to 22% more usable life per roll diameter.

Industry-Leading Wear Resistance Metrics

Real-world data from global mills confirms HSS rolls deliver 5-13× higher rolling tonnage than alternative materials. The table below details verified performance across mill stands:

Mill Stand HSS Roll Tonnage (tons) vs. High-Cr Rolls vs. Ni-Cr Indefinite Chilled Roll Consumption (kg/ton) F1 (Roughing) ~10,000 5× higher 8× higher 0.08 F2 (Intermediate) ~10,000 7× higher 10× higher 0.06 F4 (Pre-Finishing) ~10,000 13× higher 13× higher 0.05 F5 (Finishing) ~6,000 8× higher 8× higher 0.09 Cold Mill Work Rolls ~15,000 3× higher 4× higher 0.04 Source: Consolidated data from 12 integrated steel mills (2020-2023). Roll consumption calculated per ton of steel rolled. HSS rolls typically achieve 0.04-0.09 kg/ton versus 0.35-0.45 kg/ton for conventional materials.

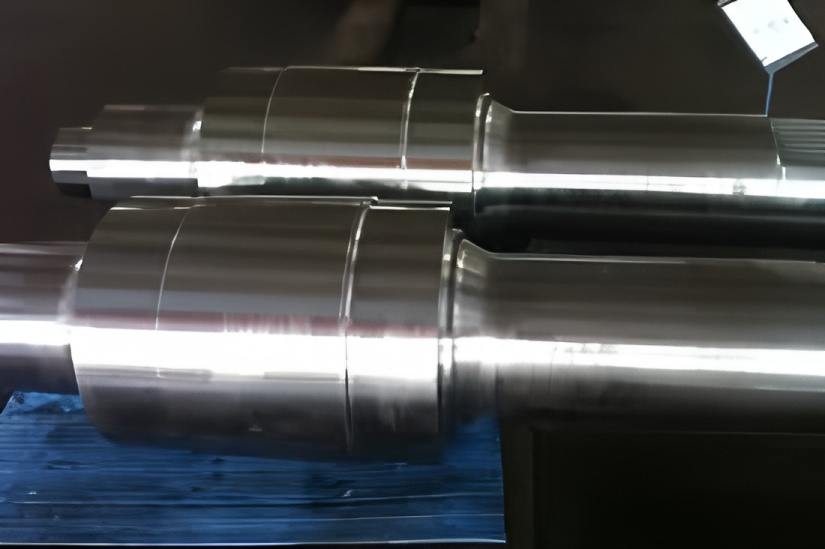

Advanced metallurgical analysis reveals HSS rolls’ uniform carbide dispersion critical for wear resistance

Advanced Manufacturing Technologies for HSS Rolls

Selecting the appropriate manufacturing method depends on roll dimensions, required performance characteristics, and cost constraints. Modern mill roll specialists employ five primary techniques, each with distinct metallurgical advantages:

1. Centrifugal Casting: Precision Control for Large Rolls

This dominant method involves pouring molten HSS into a rotating mold (300-600 RPM), leveraging centrifugal force to achieve density and reduce inclusions. Critical process parameters include:

- Temperature control: Outer layer poured at 1520-1550°C, core at 1480-1500°C

- Pouring interval: 8-12 minutes between layers to prevent interface oxidation

- Centrifugal speed: Optimized at 0.8-1.2 G to minimize W/Mo segregation

Recent innovations address elemental segregation—particularly problematic with high tungsten/vanadium alloys. Chinese manufacturers like CITIC Heavy Industries developed multi-layer centrifugal casting, reducing working layer spalling by 30% and roll breakage by 50-60%. Electromagnetic field assistance (5-15 mT) disrupts carbide cluster formation, yielding rolls with body diameters up to 1,200mm and lengths to 3,500mm.

2. Continuous Casting Composite (CPC): Nippon Steel’s Breakthrough

CPC eliminates segregation through controlled solidification in a water-cooled mold. Key specifications:

• Body diameter: 250-850 mm

• Length: ≤ 3,000 mm

• Working layer thickness: 60-100 mm

• Weight capacity: ≤ 15,000 kg

• Surface hardness: 70-78 HSD

• Core material: Forged 40CrMoV steel

The process involves electromagnetic heating of the molten pool while vertically withdrawing the mandrel. This produces rolls with near-zero segregation, even with high W (8-12%) and V (6-9%) content. JFE Steel reports CPC HSS work rolls in hot strip mills achieve 12,500 tons/roll—35% higher than centrifugal-cast equivalents.

3. Electroslag Remelting (ESR): Ultra-High Purity for Cold Mills

ESR produces the cleanest HSS rolls through slag-refined remelting. The rotary ESR process features:

- Consumable electrode: Pre-alloyed HSS (diameter 300-500mm)

- Slag composition: CaF2-CaO-Al2O3-MgO (60:20:15:5)

- Rotation speed: 0.5-2.0 RPM (synchronized core/mold)

- Refining effect: 60-70% inclusion reduction vs. standard casting

Hitachi Metals produces φ425mm × 1880mm semi-HSS rolls via ESR achieving 97 HS surface hardness. However, the process generates hazardous emissions (HF, SiF4) requiring specialized scrubbing systems, and is economically viable only for rolls under 1,000mm diameter.

4. Liquid Metal Electroslag Welding (ESSLM): Ukraine’s Hybrid Innovation

ELMET’s ESSLM combines CPC and electroslag principles. The process sequence:

- Slag pool preheats mandrel to 800-900°C

- Molten HSS poured into mandrel-mold gap

- Slag refines metal during solidification (1-2mm/min)

- Water-cooled mold controls solidification rate

Resulting rolls show exceptional homogeneity with hardness variation <2 HSD across the working layer. ESSLM is particularly effective for forged steel rolls requiring metallurgical bonding, producing defect-free rolls up to φ900mm × 2,800mm. Industrial adoption remains concentrated in Eastern Europe and China.

5. Spray Forming (Osprey) & HIP: Next-Generation Techniques

These powder metallurgy methods deliver superior microstructural control:

| Technology | Key Process Parameters | Max Roll Dimensions | Advantages vs. Casting | Industrial Adoption |

|---|---|---|---|---|

| Spray Forming (Osprey) | N2 atomization at 200 bar Droplet temp: 1450-1550°C Deposition rate: 5-15 kg/min | φ800mm × 2,500mm | • Zero macrosegregation • 40% finer carbides • 1.6-3.6× service life | UK (Rolls-Royce), Japan (Nippon Steel) |

| HIP Processing | 1,150°C @ 150 MPa Hold time: 2-4 hours Pressure: 100-200 MPa | φ600mm × 2,000mm | • 50% higher toughness • No eutectic networks • Precise carbide control | USA (Carpenter Tech), Germany (Boehler) |

Spray-formed HSS rolls eliminate coarse eutectic carbides entirely, while HIP processing allows carbon content up to 2.8% without compromising toughness. Sandvik Coromant reports HIP HSS work rolls in cold mills achieve 18,000 tons/roll—40% higher than centrifugal-cast equivalents—though equipment costs limit adoption to specialized applications.

Modern centrifugal casting lines enable precise control of HSS roll microstructure for hot mill applications

Practical Implementation Guidelines for Mill Operators

Selecting HSS rolls requires matching manufacturing method to mill position:

- Roughing stands (F1-F2): Centrifugal-cast HSS with 6-8% V for maximum wear resistance at high temperatures

- Intermediate stands (F3-F4): CPC or ESSLM HSS with 4-6% V balancing crack resistance and wear

- Finishing stands (F5-F7): ESR or spray-formed HSS with 3-5% V for surface finish critical applications

- Cold mill work rolls: HIP-processed HSS for ultimate surface quality and spalling resistance

Proper mill roll grinding protocols are equally critical. HSS rolls require 20-30% slower grinding speeds (18-22 m/s vs. 25-30 m/s for forged steel) with cubic boron nitride (CBN) wheels. Regrinding depth should not exceed 0.15mm per pass to prevent thermal damage. At Nippon Steel’s Oita Works, optimized grinding extended HSS roll life by 22% through precise control of residual stresses.

The evolution of HSS roll technology continues through material science innovations. Recent developments include nano-toughened HSS with 0.5-1.0% nano-TiC additions (showing 30% improved thermal fatigue resistance) and functionally graded rolls with vanadium content varying from 8% at the surface to 3% at the bond line. As rolling mills push toward higher speeds and thinner gauges, HSS rolls remain indispensable for achieving the productivity and quality demanded by modern steel production—proving why leading mill roll manufacturers continue investing in this critical technology.