In cold rolling operations, the performance of cold work rolls directly determines product quality, surface finish, and overall mill efficiency. Selecting the appropriate rolling mill roll hardness and materials is critical for achieving optimal strip thickness uniformity, extended roll service life, and minimized downtime. This comprehensive guide explores the essential factors in cold mill roll selection, hardness specifications, material properties, and advanced shape control techniques used in modern cold rolling mill rolls production.

Key Takeaways

- Work roll body hardness: 95–100 Shore (≈62–65 HRC)

- Backup roll hardness: 60–65 Shore (lower than work rolls)

- Recommended backup roll replacement cycle: 6 months

- Work roll materials: Forged alloy steel, high-chrome steel, tungsten carbide composite

- Surface finish requirements: Ra 0.2–0.8 μm depending on application

Understanding Cold Work Roll Surface Requirements

The surface quality of cold mill rolls represents one of the most critical factors in strip production. Unlike hot rolling operations where scale formation is inevitable, cold rolling demands absolutely defect-free roll surfaces. Any surface imperfection—whether scratches, dents, or adhered material particles—will directly transfer to the rolled strip, creating quality defects that cannot be corrected in subsequent processing stages.

Cold work rolls are engineered with a distinctive metallurgical structure: a hard, wear-resistant surface layer combined with a tough, ductile core. This dual-property design ensures that the roll can withstand the extreme contact pressures encountered during rolling while maintaining sufficient toughness to resist catastrophic failure from impact loads or thermal shock.

Industry Standard: For aluminum foil rolling, surface roughness values as low as Ra 0.05 μm may be required, while general-purpose cold rolling of steel strip typically specifies Ra 0.4–1.2 μm depending on the final product application and subsequent coating requirements.

Hardness Specifications for Work Rolls and Backup Rolls

The relationship between work roll material hardness and backup roll hardness follows a fundamental principle: backup rolls must always be softer than work rolls to prevent surface damage during operation and grinding. This hardness differential ensures that any contact stress between rolls preferentially deforms the backup roll rather than damaging the critical work roll surface.

| Roll Type | Body Hardness (Shore) | Body Hardness (HRC) | Neck Hardness (Shore) | Typical Material |

|---|---|---|---|---|

| Work Roll (Standard) | 95–100 | 62–65 | 45–50 | Forged Alloy Steel |

| Work Roll (High-Chrome) | 100–105 | 65–68 | 48–52 | 5% Cr Steel |

| Work Roll (Tungsten Carbide) | N/A | 82–87 HRA | N/A | WC-Co Composite |

| Backup Roll | 60–65 | 52–56 | 40–42 | Forged Steel/Cast Steel |

Work Roll Hardness Considerations

The specified hardness range of 95–100 Shore (approximately 62–65 HRC) for cold rolling mill rolls represents an optimal balance between wear resistance and toughness. Higher hardness values improve wear resistance and maintain surface finish longer but increase susceptibility to surface cracking and spalling under thermal cycling conditions.

The neck hardness specification of 45–50 Shore ensures adequate toughness in the bearing journal areas where bending moments are highest. This deliberate hardness gradient from body to neck is achieved through controlled heat treatment processes, with the body receiving deep cryogenic treatment while the necks are tempered to lower hardness levels.

Backup Roll Hardness and Fatigue Management

Backup rolls operate under high contact stress and frequent alternating loads during rolling operations. The standard hardness range of Shore 60–65° (approximately 52–56 HRC) provides adequate support for work rolls while maintaining sufficient fatigue resistance. The neck hardness of approximately Shore 42° accommodates the bearing loads transmitted through roll chock assemblies.

Under continuous service conditions, backup rolls are subject to contact fatigue that may result in surface spalling. When minor spalling occurs, the affected area can often be cleaned and dressed, allowing continued use if the spalling depth remains within acceptable limits. However, many modern mills implement strict replacement protocols requiring immediate roll change and regrinding regardless of spalling extent to maintain consistent product quality.

⚠️ Maintenance Recommendation: To minimize spalling risk, backup rolls should undergo stress relief annealing after approximately six months of continuous use. This heat treatment process relieves accumulated residual stresses from rolling contact and thermal cycling, extending roll service life by 30–50%.

Material Selection for Cold Mill Rolls

Selecting the appropriate work roll material requires careful consideration of the rolled product, mill configuration, production volume, and economic factors. Modern cold rolling mills employ various roll materials, each offering distinct advantages for specific applications.

| Material Type | Composition | Hardness | Applications | Service Life | Relative Cost |

|---|---|---|---|---|---|

| 2% Cr Forged Steel | C: 0.8–0.9%, Cr: 1.8–2.2%, Mo: 0.3% | 60–64 HRC | General cold rolling | Standard | 1.0× |

| 5% Cr Forged Steel | C: 0.85–0.95%, Cr: 4.8–5.2%, Mo: 0.5%, V: 0.1% | 64–68 HRC | High-reduction rolling | 1.5× Standard | 1.3× |

| High-Speed Steel (HSS) | C: 0.8–1.0%, Cr: 4%, W: 6%, Mo: 5%, V: 2% | 66–70 HRC | Stainless steel rolling | 2× Standard | 2.5× |

| Semi-HSS | C: 0.6–0.8%, Cr: 5%, Mo: 3%, V: 1% | 64–67 HRC | Tin plate, automotive | 1.8× Standard | 1.8× |

| Tungsten Carbide Composite | WC: 85–90%, Co: 10–15% | 82–87 HRA | Wire rod, section rolling | 5–10× Standard | 8× |

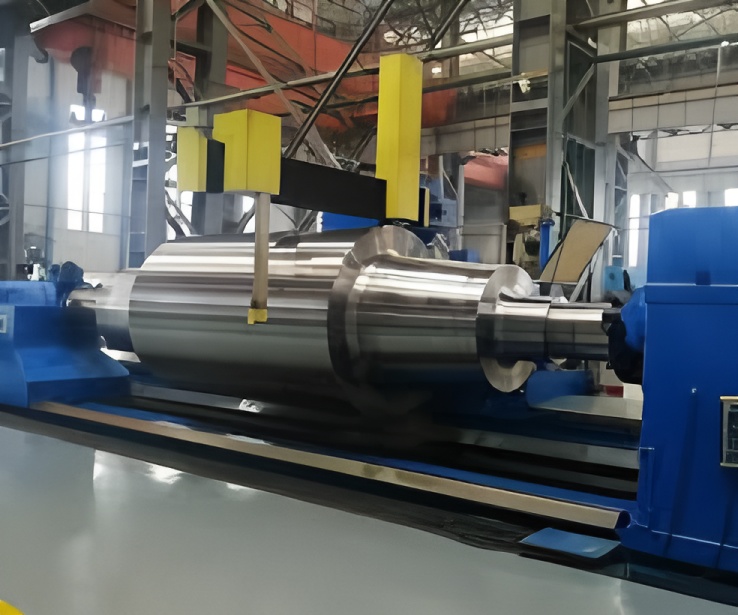

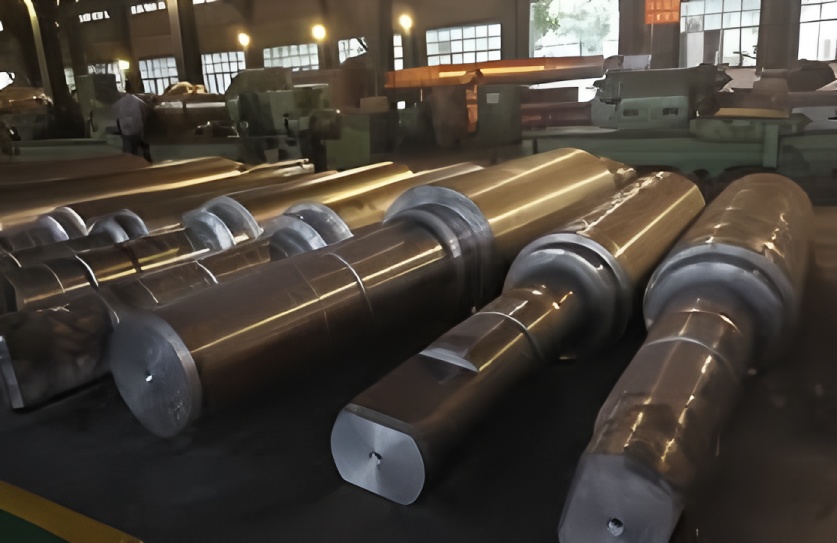

Forged Alloy Steel Work Rolls

Forged alloy steel remains the predominant material choice for cold mill rolls due to its excellent combination of hardness, toughness, and grindability. The forging process produces a refined grain structure with improved mechanical properties compared to cast alternatives. High-quality forged work rolls exhibit uniform hardness distribution across the barrel length, essential for consistent strip thickness control.

The 5% chromium steel grade has become increasingly popular for demanding applications, offering approximately 50% longer service life compared to conventional 2% chromium grades. The higher chromium content forms stable chromium carbides that enhance wear resistance without significantly compromising toughness.

Tungsten Carbide Rolls for Specialized Applications

For applications requiring extreme wear resistance, tungsten carbide rolls offer unparalleled performance. These rolls typically employ a tungsten carbide ring shrunk onto a steel core, combining the wear resistance of cemented carbide with the toughness and economy of steel construction. Tungsten carbide roll rings can achieve 5–10 times the service life of conventional steel rolls in wire rod and section rolling applications.

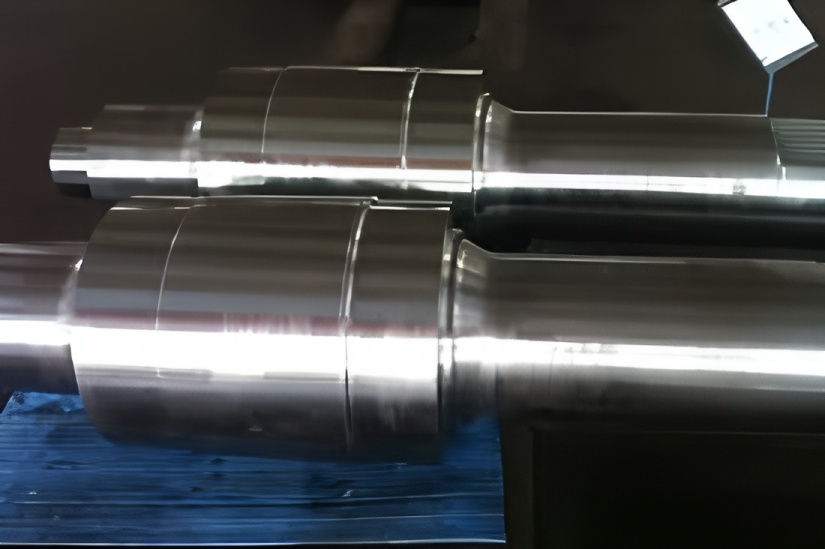

Roll Grinding and Crown Configuration

Proper roll grinding represents a critical maintenance operation that directly affects strip quality and rolling stability. During cold rolling, rolls experience two distinct types of deformation that must be compensated through pre-grinding:

Load-Induced Crown

Roll deflection caused by rolling pressure creates a concave roll gap profile. This effect increases with strip width and rolling force.

Thermal Crown

Non-uniform thermal expansion from frictional heating creates a convex roll profile. This effect varies with rolling speed and cooling efficiency.

To compensate for these effects, rolls are pre-ground with a specific curve known as the roll crown. Cold rolling primarily involves controlling load-induced crown through positive (convex) grinding profiles. The crown magnitude depends on multiple factors including reduction rate, strip yield strength and width, roll heating conditions, material properties, rolling tension, and lubricant performance.

Roll Configuration Guidelines

Roll configuration refers to how the required total crown is distributed among the rolls in a mill stand. The configuration must consider grinding convenience, adjustment flexibility, and product quality requirements.

| Mill Type | Crown Configuration | Typical Crown Values |

|---|---|---|

| Two-High Mill | Crown applied to both upper and lower work rolls; alternatively, crown only on upper roll with cylindrical lower roll | 0.05–0.30 mm total |

| Four-High Mill (Small Crown) | Crown on upper work roll only; backup rolls cylindrical | 0.02–0.10 mm |

| Four-High Mill (Large Crown) | Total crown distributed evenly between upper and lower work rolls; backup rolls cylindrical | 0.15–0.40 mm total |

The crown profile must be centered symmetrically along the roll barrel length, with smooth transitions toward both ends. Any asymmetry in crown distribution will cause strip camber and edge wave defects that cannot be corrected without roll replacement.

Work Roll Shape Control Methods

During strip rolling, variations in rolling pressure and thermal deformation cause dynamic roll shape changes that lead to uneven strip thickness or wave formation. Waves may appear at the center (center buckle) or edges (quarter buckle or edge wave), indicating uneven pressure distribution across the strip width. Excessive waving can result in scrap generation or strip breaks that damage equipment and reduce productivity.

1. Conventional Shape Control

At lower rolling speeds, wave formation can be mitigated by adjusting operational parameters including spray cooling distribution, roll bending force, front and back tension, reduction rate, and rolling speed. The appropriate adjustment depends on the wave size, position, and persistence.

2. Hydraulic Roll Bending for Shape Control

Hydraulic systems installed on backup or work roll bearings enable active roll bending for rapid shape adjustment. This method significantly improves flatness control, especially during high-speed rolling where thermal transients occur rapidly.

Edge Waves Correction

Increase positive bending force (P) or reduce negative bending force (Q) to enhance roll crown through positive bending action.

Center Waves Correction

Increase negative bending force (Q) or reduce positive bending force (P) to reduce crown through negative bending action.

3. Automatic Shape Control Systems

Modern cold rolling mills are equipped with shape meters (shapemeters) integrated with hydraulic bending, roll tilt, rolling force, cooling, and tension systems through computer control. This closed-loop automatic shape regulation enables real-time flatness correction with response times measured in milliseconds, maintaining strip flatness within ±5 I-units across the full speed range.

Tension Control in Cold Rolling

Modern strip rolling mills employ robust entry and exit tension systems that profoundly influence strip flatness, rolling force, and process stability. Proper tension control is essential for producing high-quality cold rolled strip.

| Parameter | Typical Value | Notes |

|---|---|---|

| Unit Tension (Steel) | 15–35% of yield strength | Higher values for final passes |

| Unit Tension (Aluminum) | 50–60% of yield strength | Consider material plasticity and edge condition |

| Tension Adjustment Range | 10:1 to 20:1 | Full control range capability |

| Tension Stability Requirement | ±1–3% | Fluctuations cause layer misalignment |

| Maximum Tension Limit | <100% of yield strength | Never exceed strip yield strength |

Front tension can exceed the strip’s yield strength slightly, helping to minimize wave formation from uneven elongation and improving overall flatness. Increased tension reduces rolling force requirements, with back tension having a more significant effect than front tension on force reduction.

💡 Technical Insight: As rolling passes increase, work hardening progressively raises the strip’s yield strength. Therefore, unit tension should be gradually increased with each pass to maintain optimal rolling conditions. The uncoiling tension for subsequent passes should be lower than the previous coiling tension to prevent interlayer slippage and surface damage.

Maintenance and Service Life Optimization

Maximizing the service life of cold rolling mill rolls requires systematic maintenance programs that address both surface condition and metallurgical stability. The following practices have proven effective in extending roll campaigns:

- Regular inspection intervals: Visual and ultrasonic inspection every 500–1000 tons of production

- Preventive grinding: Schedule grinds based on tonnage rather than visible damage

- Stress relief treatment: Perform after 6 months of service for backup rolls

- Proper storage: Support rolls horizontally on V-blocks to prevent bending

- Temperature monitoring: Track roll surface temperatures during rolling to optimize cooling

- Lubrication management: Maintain consistent lubricant film for uniform wear patterns

Summary: Critical Selection Factors

Work Roll Hardness:

95–100 Shore (62–65 HRC)

Backup Roll Hardness:

60–65 Shore (52–56 HRC)

Material Choice:

Forged alloy steel for most applications

Service Interval:

6-month grinding/annealing cycle

Selecting the optimal hardness and material for cold work rolls requires balancing wear resistance, fatigue strength, and economic considerations. By understanding the relationships between roll properties and rolling performance, mill operators can make informed decisions that maximize productivity while minimizing roll consumption costs. Proper maintenance programs, including regular grinding and stress relief treatments, ensure consistent roll performance throughout the service life.