Description: This article analyzes common issues in hot-rolled narrow strip steel production, such as irregular spalling, roll ring cracking, and groove pitting. It proposes effective solutions including improving roll cooling, increasing roll ring width, and selecting appropriate roll materials to enhance performance and reduce costs.

Keywords: Steel mill roll, roll life, production cost, roll maintenance

Optimizing the steel rolling process and enhancing roll device performance through technical measures can significantly improve roll hardness, thermal crack resistance, and impact resistance. These improvements extend roll service life and reduce consumption, thereby lowering production costs.

The Importance of Extending Roll Life

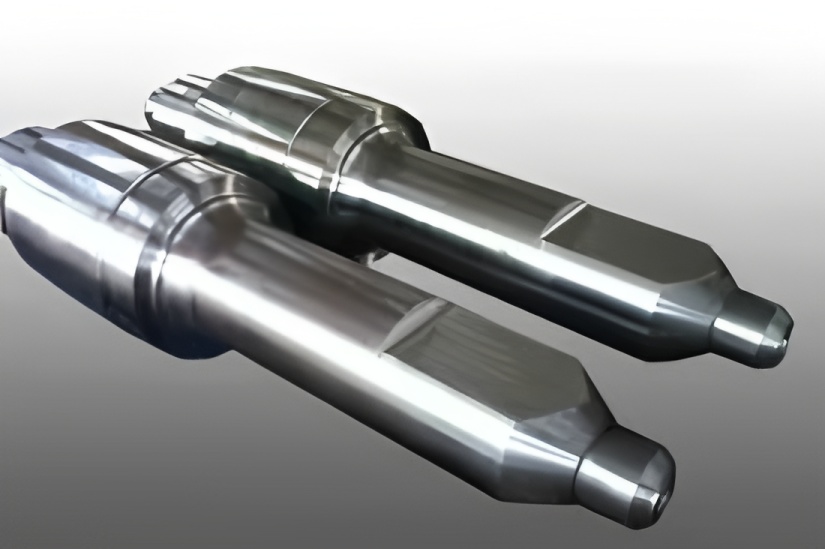

Rolls are critical components in rolling mills, subjected to continuous metal plastic deformation. They represent a significant portion of production costs due to their high consumption rate. Implementing a comprehensive roll management system allows managers to track each roll’s condition and usage, optimize pairings, maximize utilization, and determine appropriate grinding amounts. This reduces roll fatigue, ensures compliance with production standards, minimizes abnormal roll changes, improves rolling line efficiency, and increases overall benefits. A well-managed roll system is essential for reducing production costs and extending service life.

Dedicated personnel should manage rolls, maintaining detailed records for acceptance, usage, cracking, and abnormal removals. Such management controls each roll’s trajectory and condition, which is vital for reducing consumption and extending life.

Common Roll Problems in Production

Irregular Spalling in the Rolling Groove

Excessive copper components in the groove center can cause irregular spalling. Copper flow during heating forms low-melting-point phases, reducing thermoplasticity and causing surface cracks. As copper continues to move, cracks expand, leading to spalling. For example, in hot-rolled narrow strip steel, inconsistent groove wear due to inadequate daily supervision and incomplete crack removal during repairs can lead to rapid crack growth and macroscopic failure.

Roll Ring Cracking

Roll rings are affected by assembly, thermal, and rolling stresses. The tangential tensile stress at the inner diameter is particularly high. Single-material roll rings are less durable, and localized stress increases can cause cracking under combined stresses.

Groove Pitting

Pitting appears as rough, uneven surfaces, often continuous but sometimes partial. allowed if depth does not exceed product thickness tolerance. Causes include:

Worn finishing or pre-finishing holes, or damaged iron oxide.

Broken iron oxide pressed into the rolled piece surface then peeling off.

Roll corrosion.

Severe surface oxidation of the billet during heating.

Roll Breakage

Cracks and soft spots form due to impact, tail flicking, or steel clamping, severely affecting production and roll life. Severe cracks cause premature spalling or breakage. Causes include improper operation, poor cooling, production technology issues, and roll quality. Inadequate cooling causes surface temperature differences, accelerating thermal stress and spalling. Overheating reduces strength and wear resistance, leading to burst grooves, bonding issues, burning, or breakage. Incorrect roll material selection or human errors like rolling accidents also cause failures.

Brittle inclusions (e.g., SiO₂, Al₂O₃, silicates) in steel materials harm roll life, with severity depending on quantity, size, and type.

Process Improvement Measures

Enhancement of Roll Cooling

Improving cooling water utilization and efficiency prolongs roll life. Rolling generates significant heat, requiring cooling to maintain replacement cycles, service life, and post-processing temperature. Two cooling water systems are used: primary cooling water sprayed axially for lubrication and cooling, and secondary cooling to rapidly reduce temperature and prevent oxidation. Cooling spray rings manage roll temperature.

At high speeds (main transmission ≥1300 rpm, auxiliary ≥700 rpm), cooling water flow and pressure must be tightly controlled. Continuous, sufficient cooling is essential; overheating necessitates immediate replacement to prevent thermal fatigue cracking. A cooling rate ≥3500 L/h and pump pressure ≤0.8 MPa maintain temperature stability.

The original square box structure with holes was replaced with a solid cylindrical nozzle, adding two rows of elliptical water seams on the split wedge, covering 5–8 mm width. The split wedge receives three times more water to enhance cooling and groove life.

Optimization of Cooling Water Parameters and Supply System

Cooling water temperature should be 40–60°C. Extreme temperatures accelerate fatigue or affect recrystallization and product quality. The water supply system was upgraded from low to medium turbidity, with frequency-converted motors maintaining 0.8 MPa pressure and automatic adjustment.

Optimization of Groove Configuration

Due to insufficient cooling, the original φ550 groove for hot-rolled narrow strip steel was modified. The I-stand rolling mill uses a forced widening principle. For high-temperature K1 steel, forced widening is applied at K3 and K4, with a straight-line groove bottom and a 17.7° slope to prevent wrinkles. K6 groove size was adjusted accordingly to prevent tailing.

Roll Material Optimization

For Q215 hot-rolled narrow strip steel, the initial groove center distance was 19.0 mm with a 7.8 mm roll ring width. To prevent cracking under fatigue, the design was updated to a 22.0 mm roll gap and 10.8 mm roll ring width.

Modification of Automatic Thickness Control Configuration

Rolling force varies with entry thickness, tension, friction coefficient, and deformation resistance, affecting exit thickness. Automatic Gauge Control (AGC) uses model algorithms to adjust juicing pressure, speed, and roll gap, ensuring thickness deviation control. A hydraulic press-down system offers high precision and speed. For example, the No. 6 rolling mill for steel wire finishing has a rough rolling thickness of 27–2.7 mm with a 10% deviation rate.

Prevention of Improper Operation

To avoid roll damage:

Prevent direct contact between guides and rolls.

Strictly control cooling water switches to prevent dehydration of replaced heads.

Conduct regular inspections; stop immediately if issues are found, and process only after cooling to room temperature.

Control rolled piece material shape per process requirements to prevent excessive single rack material shape.

Cleanly cut blackheads on rolled pieces; prohibit black steel.

Adequate Repair Amounts

Ensure each groove’s output remains stable without excess cracks, which reduce rolling capacity and product quality. For example, the turning amount for Q215 hot-rolled narrow strip steel finished rolls must reach 600 mm.

Implementing these measures significantly extends roll life, reduces replacement frequency, and lowers labor intensity. Addressing irregular spalling, cracks, and pitting minimizes cooling-related grooves, improves product quality, and increases average productivity.