Types of Rolling Mill Rolls and Material Selection Guidelines

Description: The roll is the most critical component in steel rolling production. It directly contacts the rolling stock, causing plastic deformation to complete the rolling process. All other rolling mill components are designed to install, support, adjust, and replace rolls, as well as to guide and control the entry and exit of the material. Rolls operate under severe conditions including high temperature, high pressure, thermal cycling, and impact, demanding high strength, surface hardness, wear resistance, and thermal crack resistance. This article discusses the selection of roll materials, design, and usage to reduce roll investment and consumption.

Keywords: Rolling mill rolls, material selection

Overview of Rolling Mill Rolls

Position and Structure of Rolls in the Mill Stand

Central Role: All other components and mechanisms are designed to install, support, and adjust the rolls, and to guide the rolling stock correctly.

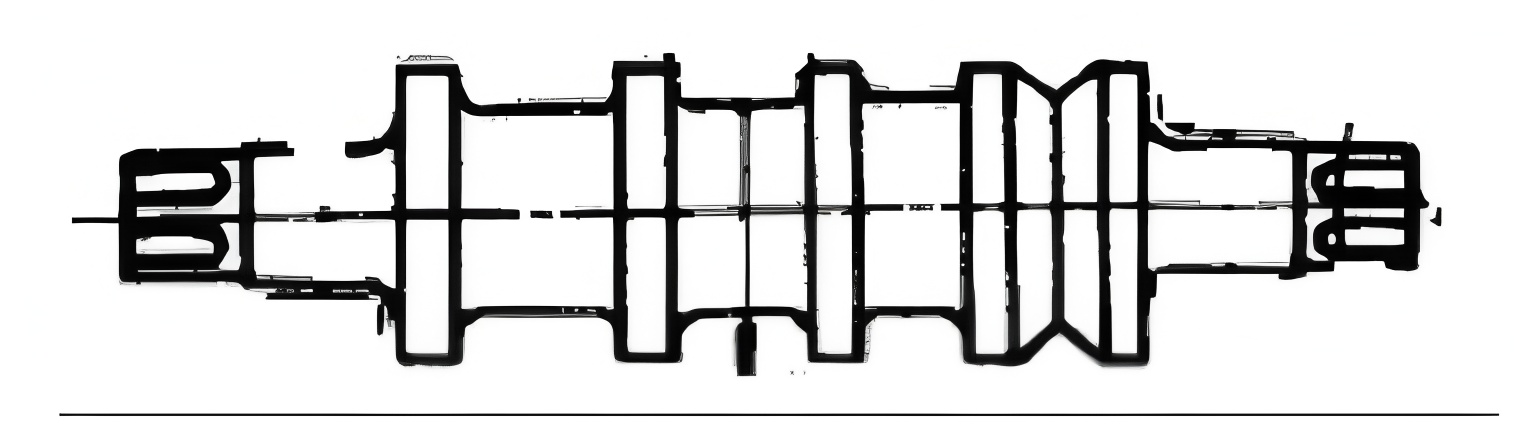

(1) Roll Body: Contacts the rolled material and induces plastic deformation.

(2) Roll Neck: The supporting part, mounted in bearings within the housing, transmitting rolling force to the frame via bearing blocks and loading devices.

(3) Roll Head: Transmits torque through a coupling connection.

Classification of Mill Rolls

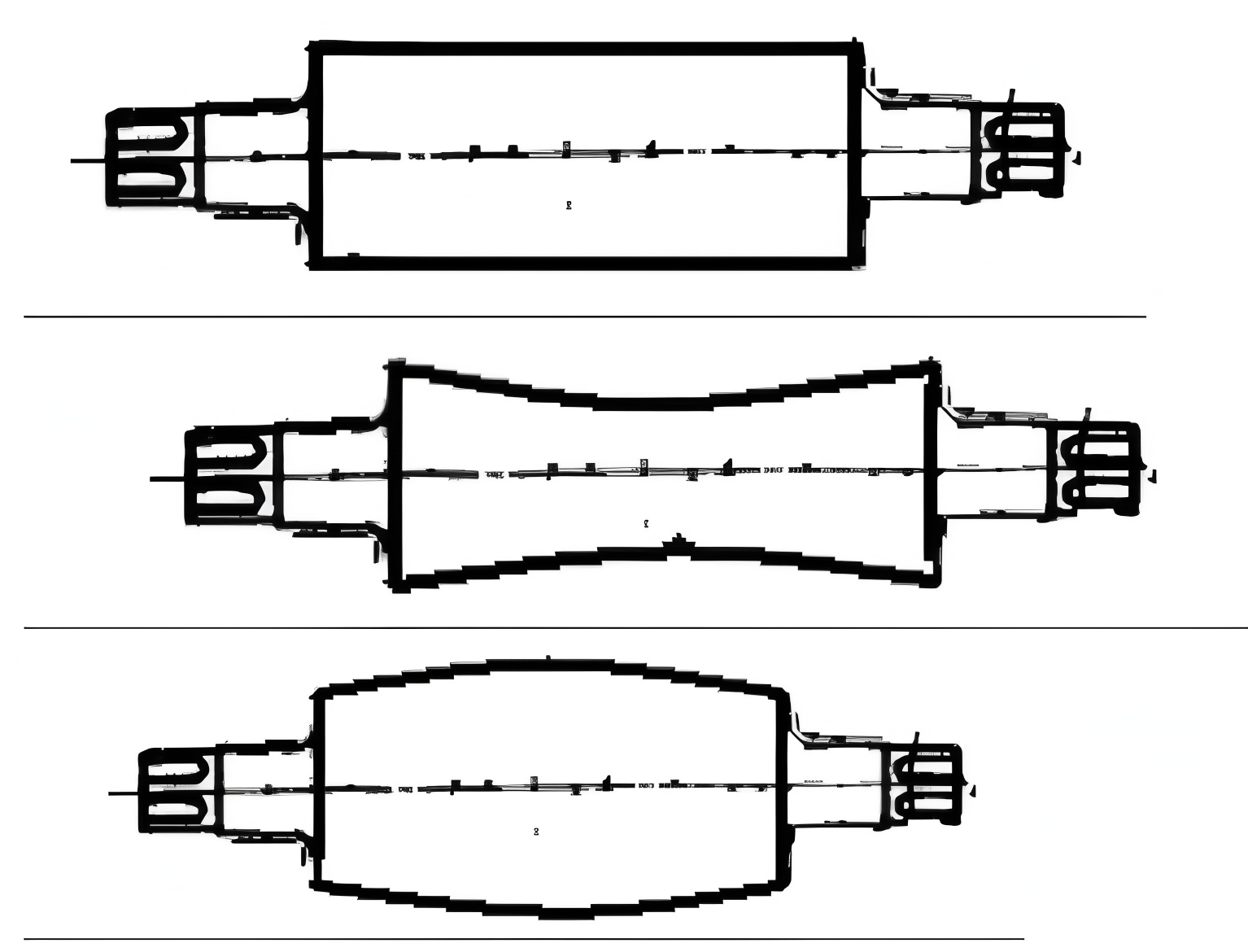

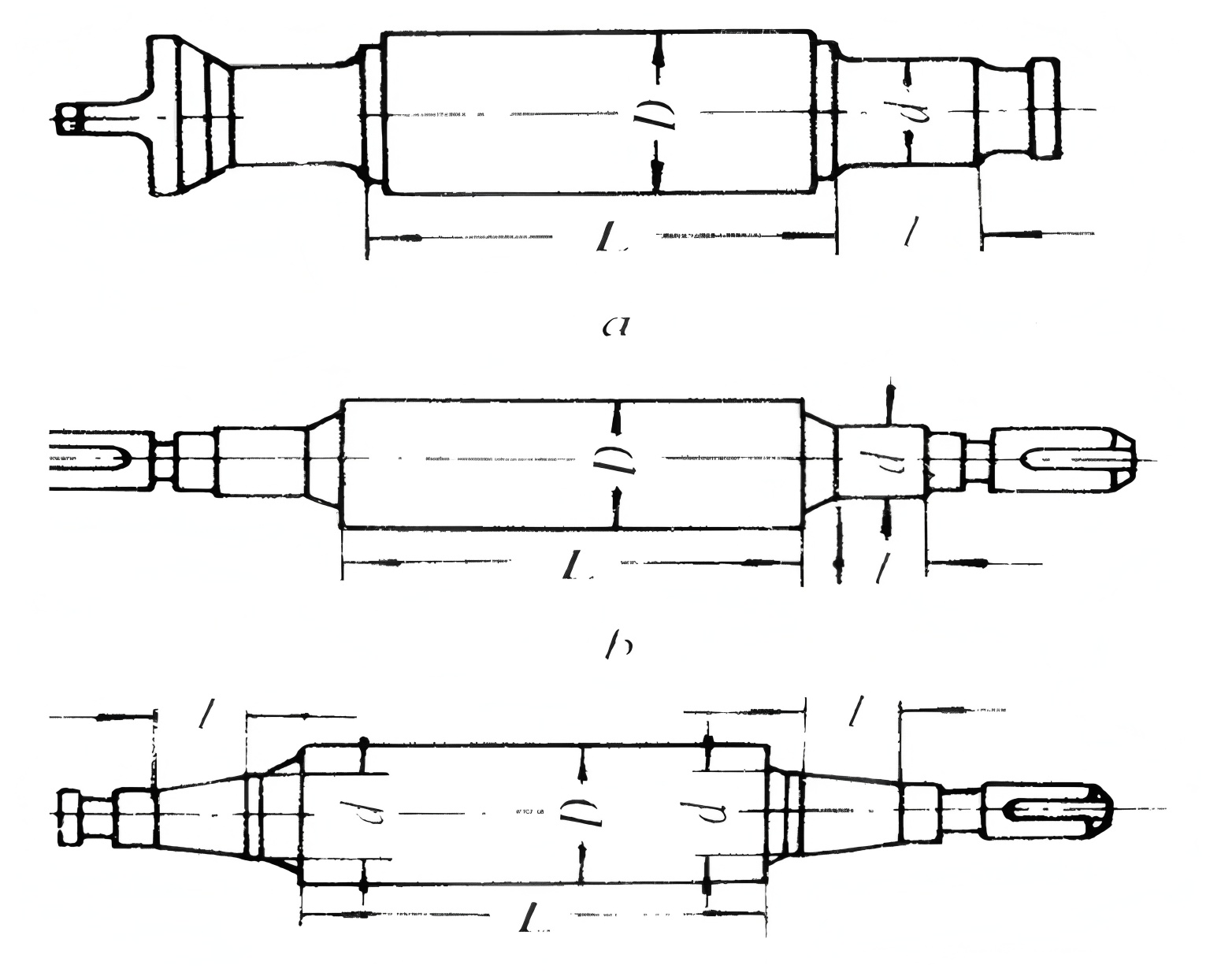

(1) Strip Mill Rolls:

Cylindrical roll body: General-purpose mills.

Concave roll body: Hot rolling, compensates for thermal expansion, controls strip shape.

Slightly convex roll body: Cold rolling, compensates for bending, controls strip shape.

Specially curved roll body (e.g., S-shaped, cigar-shaped): Used in CVC and UPC mills.

(2) Section Mill Rolls:

Feature grooves (passes) on the roll body.

(3) Special Rolls:

Used in specialized mills (e.g., piercing, wheel, gear, cross wedge rolling), with varied shapes.

Working Characteristics and Requirements for Rolls

| Characteristics | Requirements |

|---|---|

| Subject to high rolling forces, moments, and dynamic loads | High strength, stiffness, surface hardness |

| Operates under high and fluctuating temperatures | High thermal stress stability |

| Severe wear: hot rolling with hard scale, cold rolling with high contact stress | Deep hardened surface layer |

Main Parameter Design of Rolls

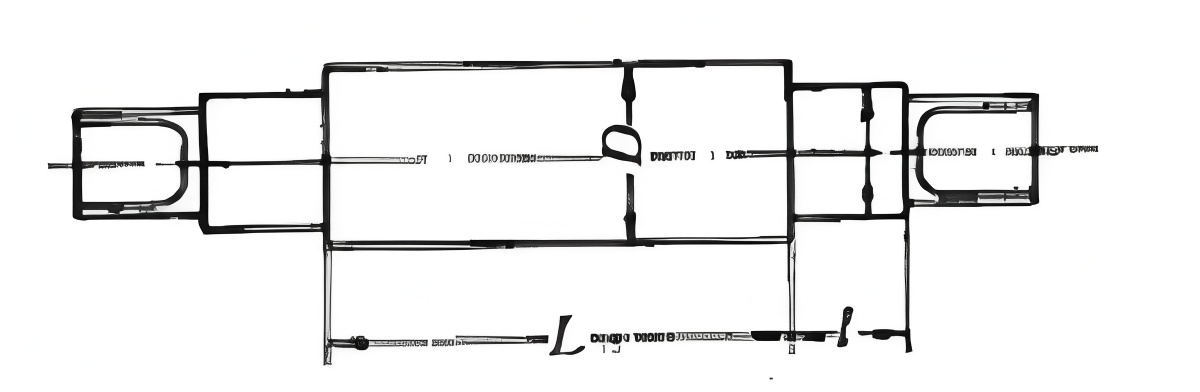

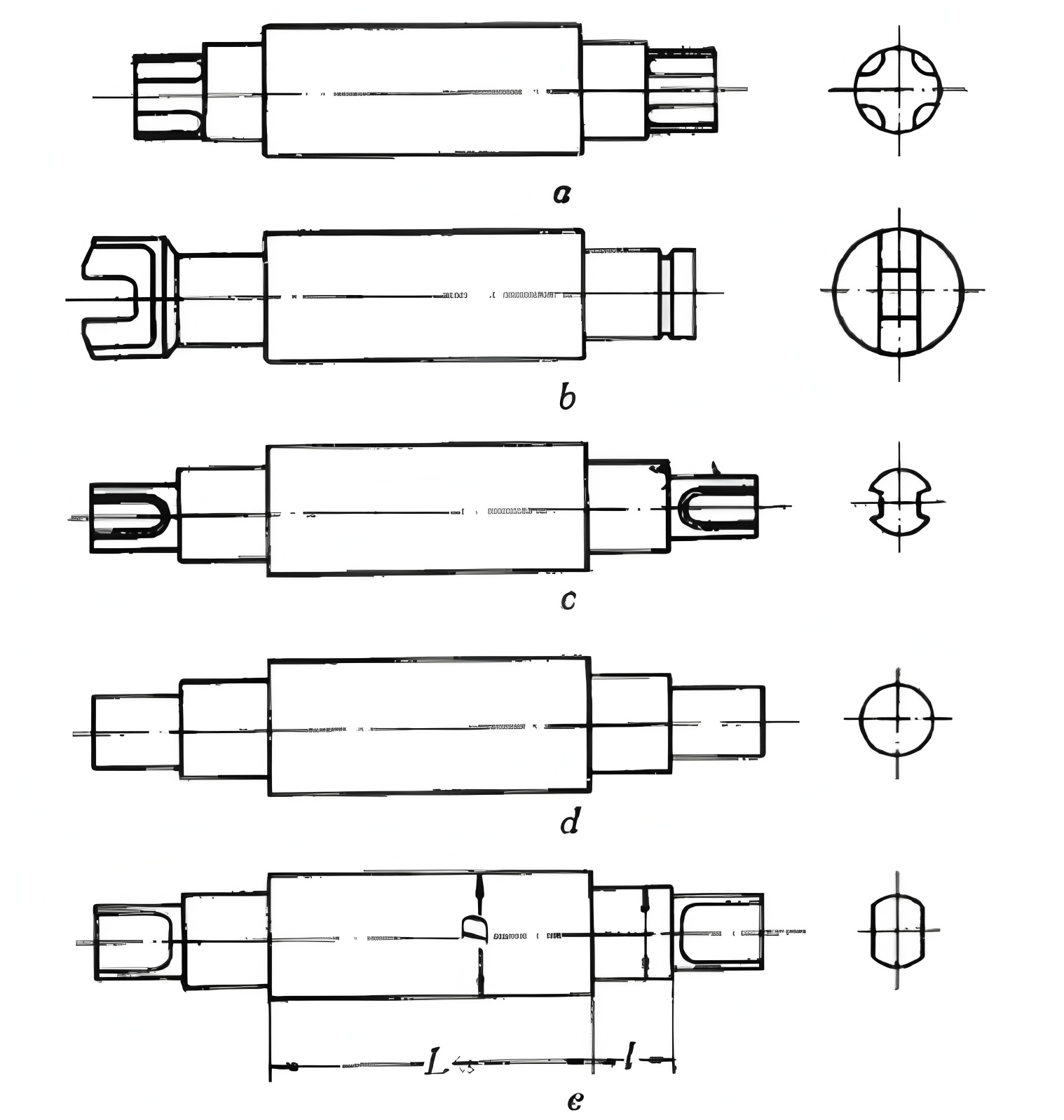

Basic parameters: Nominal diameter D, body length L, neck diameter d, neck length l, head diameter d1.

Roll Diameter Definitions:

Nominal Diameter: Center distance of gear housing; for blooming mills: outer diameter of roll ring or center distance of finishing roll.

Working Diameter: Groove bottom diameter (section mills).

Maximum Diameter: New roll diameter.

Minimum Diameter: Worn roll diameter.

Determination of Nominal Diameter and Body Length

For blooming and section mills, determine roll body diameter based on:

I. Avoid excessive groove depth: nominal-to-working diameter ratio ≤ 1.4.

II. Maximum bite angle.

III. Roll strength (safety factor n=5).

| Rolling Condition | Max Bite Angle | Max Reduction Ratio | Friction Coefficient |

|---|---|---|---|

| Hot rolling, scored/welded rolls | 24~32° | 1/6~1/3 | 0.45~0.62 |

| Section steel | 20~25° | 1/8~1/7 | 0.36~0.47 |

| Strip | 15~20° | 1/14~1/8 | 0.27~0.36 |

| Pipe rolling (piercing mill) | 12~14° | 1/60~1/40 | — |

| Cold rolling, lubricated, smooth rolls | 5~10° | 1/130~1/23 | 0.09~0.18 |

| Well-ground rolls | 3~5° | 1/350~1/130 | 0.05~0.08 |

| Palm/cottonseed oil lubricated | 2~4° | 1/600~1/200 | 0.03~0.06 |

Body Length Determination:

I. Number of passes.

II. Strength conditions.

III. Empirical values:

Strip mills: Set L first, then D.

Hot strip: Medium plate L/D=2.2–2.8; Sheet L/D=1.5–2.2.

| Mill Type | L/D₁ | L/D₂ | D₂/D₁ | Notes |

|---|---|---|---|---|

| Heavy plate | 3.0–5.2 | 1.9–2.7 | 1.5–2.2 | D₁: work roll; D₂: backup roll |

| Wide strip roughing | 1.5–3.5 | 1.0–1.8 | 1.2–2.0 | |

| Wide strip finishing | 2.1–4.0 | 1.0–1.8 | 1.8–2.2 | |

| Cold plate | 2.3–3.0 | 0.8–1.8 | 2.3–3.5 |

For cold strip, maximum work roll diameter is limited by the minimum strip thickness.

Roll Neck and Head Size Determination

Depending on bearing type: plain, rolling, or fluid film bearings.

Roll head types: splined, universal joint, keyed, cylindrical, or with flats.

Selection of Roll Material

Principles:

Based on working conditions and failure modes, ensure performance: strength, wear resistance, heat resistance.

Common Roll Materials:

(1) Alloy Forged Steel (JB/ZQ4289-1986):

Hot rolls: 55Mn2, 55Cr, 60CrMnMo, 60SiMnMo.

Cold rolls: 9Cr, 9Cr2, 9Cr2W, 9Cr2Mo, 60CrMoV, 80CrNi3W.

Pros: Good comprehensive properties; Cons: Expensive, difficult to manufacture.

(2) Cast Steel: ZG70, ZG70Mn, ZG8Cr, ZG75Mo.

(3) Cast Iron: Gray iron, alloy iron, nodular iron.

Varying hardness by casting method: semi-chilled, chilled, indefinite chilled.

Pros: High hardness, smooth surface, wear-resistant, simple manufacture, low cost.

Cons: Lower strength than steel (except nodular iron).

(4) High-Speed Steel:

Pros: Excellent wear resistance, good surface roughness retention. Developed over past 20 years with broad prospects.

Material Selection by Application:

(1) Blooming, billet, heavy plate, large rail/beam, section roughing mills:

Use forged steel rolls; alloy steel for higher demands. Cast steel often in section roughing.

Reason: High reduction, force, and impact require high strength and high friction (for good bite and reduction).

(2) Finishing stands of small/medium section mills:

Mostly cast iron or nodular iron.

Reason: Emphasis on hardness and wear resistance for accurate size, good surface, fewer changes, higher productivity.

(3) Wire rod mills:

Roughing: Annealed pearlitic nodular iron or cast steel.

If thermal cracking is main issue: lower hardness (HS=38–45).

If wear is main issue: higher hardness (HS=45–55). Prefer cast iron: at same hardness, service life is twice that of cast steel.

Intermediate stands: Pearlitic or bainitic nodular iron, higher hardness (HS=60–70).

Pre-finishing: High-Ni-Cr centrifugal composite, tool steel, tungsten carbide.

Finishing: Tungsten carbide carbide for its thermal conductivity, minimal hardness drop at high temperature, thermal fatigue resistance, wear resistance, and strength.

(4) Hot strip mills:

Work rolls: Mostly cast iron for high surface hardness.

Backup rolls: Mostly Cr-alloy forged steel for high strength and hardenability, as they mainly bear bending moment and have large diameter.

(5) Cold strip mills:

Work rolls: Mostly high-strength alloy cast steel or composite with carbide sleeve for high surface hardness and strength.

Backup rolls: Similar to hot strip, Cr-alloy forged steel, but higher hardness (HS=50–65) for strength and hardenability under bending.

Summary of Roll Types and Applications:

| Roll Type | Surface Layer Characteristics | Typical Applications |

|---|---|---|

| Chilled cast iron | Hard, brittle, high wear resistance, smooth finish | Light-duty finishing; roughing/intermediate stands |

| Indefinite chilled iron | Moderate wear, thermal crack resistance, strength | Hot strip/sheet work rolls; small section/wire rods |

| Nodular iron (chilled) | Two-high sheet mills; three-high Lauth mills | |

| Nodular iron (indefinite chilled) | Section steel rolls; heavy-duty hot strip work rolls; temper mill backup rolls | |

| Nodular iron (initial rolling) | High strength, toughness, thermal crack resistance | Blooming rolls |

| Semi-chilled cast iron | Small hardness drop, deep grooves possible | Large/medium section rolls; small roughing rolls; hot-rolled tube mills |

| Cast steel | High strength, lower wear resistance | Blooming rolls; large/medium roughing; hot strip backup rolls; vertical rolls; piercing mills |

| Semi-steel | Balance of strength and wear, small hardness drop | Light/medium blooming; section rolls; hot strip work rolls; hot-rolled tube rolls |

| Forged steel (hot) | High strength, non-sticking (non-ferrous) | Blooming rolls; non-ferrous metal rolls; backup rolls |

| Forged steel (cold) | High strength, wear resistance, surface quality | Cold work rolls |

| High-chromium steel | Good wear resistance, strength, toughness | Hot strip roughing/pre-finishing; cold strip work rolls; small section/wire finishing |

| Tungsten carbide | Excellent wear, minimal flattening, high precision | Small rounds, bar, wire rods; high-speed wire ring rolls; 20-high mill work rolls |