Description:

This paper studies and analyzes the application of high-speed steel rolls in hot-rolled strip production. It highlights the broad prospects of these rolls based on their wear resistance, chemical composition, heat resistance, and mechanical properties. Solutions and recommendations are provided to address issues encountered during the production of steel rolls in hot-rolled strip mills.

Keywords: High-speed steel rolls, hot-rolled strip production

High-chromium cast iron has traditionally been used for work rolls in the front stands of finishing mills in hot strip continuous rolling processes. It forms a hard, wear-resistant high-chromium oxide film on the roll surface through contact with the high-temperature strip, thereby extending roll service life. The formation of this oxide film is a dynamic process highly dependent on cooling and rolling conditions, which directly influence its density and thickness. Due to the complexity of controlling these conditions, achieving an ideal oxide layer is challenging. As a result, when high-speed steel rolls are used in hot-rolled strip production, oxide spalling can occur, adversely affecting strip surface quality and roll service life.

Enhancements in High-Speed Steel Rolls

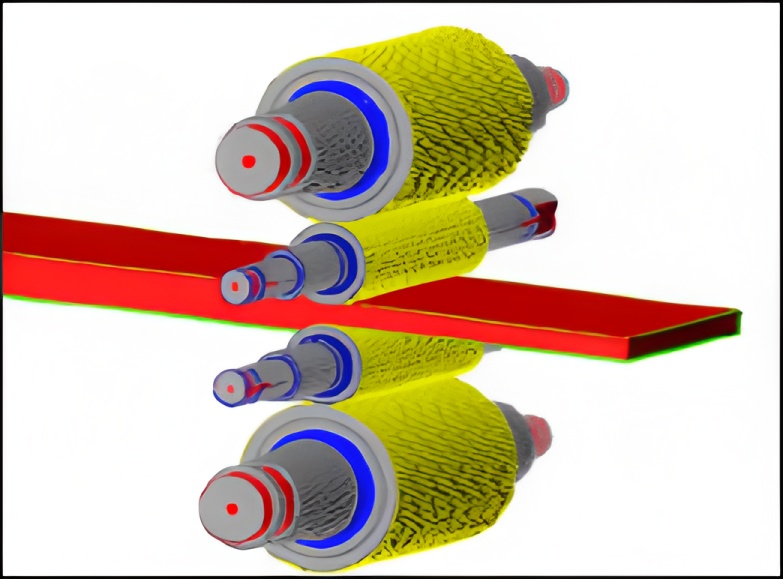

By modifying the chemical composition and improving the matrix structure, the wear resistance of high-speed steel rolls has been significantly enhanced. After more than a decade of technological refinement, these rolls are now effectively employed in hot strip finishing mills. Combined with lubrication processes, this innovation not only improves product quality but also substantially reduces production costs. The high-speed steel composite roll features a defect-free metallurgical bond between the core and the outer layer. The core offers high tensile strength and strong bonding layer integrity, increasing the roll’s bending resistance and contributing to better strip shape.

Excellent Wear Resistance

Comparative studies show that high-speed steel rolls exhibit superior wear resistance under identical mill stand and operating conditions. Given their good surface condition even after use, the number of regrinding cycles per roll can be increased. This reduces both grinding workload and production costs. The rolling capacity per millimeter of high-speed steel rolls is approximately 26–28 times greater than that of high-chromium iron rolls, offering significantly improved cost efficiency.

Superior Thermal Crack Resistance

Owing to their unique microstructure, high-speed steel rolls effectively inhibit crack initiation. Practical applications confirm their better thermal crack resistance compared to high-chromium cast iron rolls. In the event of common production incidents, the effects can often be mitigated through light regrinding, simplifying processing and reducing costs.

The friction coefficient of high-speed steel rolls ranges between 0.40–0.44, higher than that of high-chromium iron rolls. When used in the F-stand, these rolls improve bite conditions and increase rolling force. This can be counteracted by implementing process lubrication to reduce rolling force.

Optimization and Inspection of High-Speed Steel Rolls

The high wear resistance, hardness, and friction coefficient of high-speed steel rolls pose challenges in grinding and quality control, such as reduced grinding efficiency, vibration marks, difficulties in roll shape control, and surface roughness management. Manufacturers can address these by selecting appropriate grinding wheel materials and adjusting parameters like hardness and grain size to enhance grinding efficiency. Optimizing grinding parameters—such as controlling feed rate and current during fine grinding, adopting variable speed control, and ensuring smooth finishing passes—ensures that the surface quality of high-speed steel rolls meets production requirements.

Application of Process Lubrication

Lubrication in the finishing mill reduces rolling force, energy consumption, and roll wear, while improving roll surface condition and strip quality. A process lubrication system mixes oil and water, spraying the emulsion onto the roll surface to form a continuous lubricating film. This film reduces the friction coefficient between the work roll and the strip, decreasing rolling force, mill vibration, and roll wear. Used in conjunction with roll gap spraying (to prevent oxide spalling), this technology effectively minimizes oxide film loss, reduces roll surface temperature in the deformation zone, and lowers thermal cycling stress, thereby preventing crack formation.

In practice, combining process lubrication with high-speed steel rolls counteracts the increased rolling force caused by their higher friction coefficient, improving product quality and reducing roll consumption and energy consumption.

Inspection of High-Speed Steel Rolls

To ensure reliable performance, high-speed steel rolls must undergo strict inspection. Issues generally arise from:

Mechanical Impact: causing surface cracks.

Production Incidents: such as cobbling. Although high-speed steel rolls have good thermal crack resistance, prompt operator response is essential to prevent defects. Stacked steel may cause spalling, requiring post-incident eddy current testing. If cracks are detected, they must be ground out. Ultrasonic testing or surface wave testing can confirm defect presence and extent. Dye penetrant or magnetic particle inspection may also be used, followed by angle probe measurement to determine crack depth and necessary grinding allowance.

Although high-speed steel rolls resist thermal cracking well, they are sensitive to mechanical cracks. Any mechanical damage must be ground out to prevent spalling or breakage during production. Eddy current or surface wave testing should be performed after any mechanical impact to ensure no cracks are present.

PC FC Shape Control Optimization

Due to differences in physical and chemical properties—such as thermal expansion coefficient, friction coefficient, elastic modulus, and hardness—between high-speed steel rolls and high-chromium or ICDP rolls, roll shape adjustments are necessary. After rolling, cooling water should be stopped immediately, and the stop time recorded before replacing the roll. Temperature measurements should be taken at 2-meter intervals from the roll body center, with 21 points across the roll body, every 10 minutes. Temperature distribution data helps optimize the thermal model. The roll is then air-cooled to room temperature, and the wear curve is measured by the grinder and fed back to the PC FC system to optimize the wear model.

The continuous adoption of new technologies to enhance product quality, precision, and cost efficiency remains a key direction in rolling technology. High-speed steel rolls, with their excellent wear and thermal crack resistance, contribute to improved product quality and reduced production costs—though they also present certain limitations. Therefore, ongoing summarization and learning from practical experience with high-speed steel rolls are essential.