Considering the complex cross-sections of large and medium section steels and the varying performance requirements for rolls at different stands, this article identifies key factors in roll material selection for roughing, intermediate, and finishing units. It proposes specific material and hardness control ranges suitable for each stand.

Keywords: Large and medium section steel mill; rolling mill rolls; material selection

Characteristics of Large and Medium Section Steel Rolling Mills

The cross-sections of large and medium section steels are generally complex, leading to highly non-uniform metal deformation within the roll grooves during rolling. Due to differences in temperature, deformation, and relative roll surface speed across the profile, temperature stress and rolling force vary significantly, causing uneven wear in different parts of the groove. This complicates the causes of roll failure.

Horizontal rolling mills for large and medium sections are typically reversible. These mills employ rolls with deep grooves. To ensure dimensional accuracy of the rolled product, the hardness from the roll surface to the groove bottom should be relatively uniform to promote even wear within the groove. Moreover, because the grooves are deep, the effective roll diameter is reduced. Thus, rolls must possess sufficient strength and toughness to prevent roll body fracture or neck damage.

Rolling Mill Stands and Roll Material Selection

Based on varying rolling loads and tasks, the rolling mill is divided into the roughing unit, intermediate unit, and finishing unit. Different roll materials and properties are required to suit the specific working conditions of each stand.

3.1 Roughing Unit

Rolls in the roughing stands primarily perform breakdown rolling. They usually have deep grooves and operate under high temperatures and high rolling pressures, requiring high strength and thermal crack resistance. To ensure surface quality and billet dimensions, certain wear resistance is also necessary. Additionally, due to the large cross-section and complex groove shape, good bite performance is essential.

Most mills use forged steel or cast steel rolls made from materials such as 60CrMo and 60CrNiMo. These provide adequate strength and toughness to meet roughing stand requirements.

NiCrMo series alloy cast steel rolls, through proper composition control and special heat treatment, achieve a tempered sorbitic structure. The Ni content refines the grain and strengthens the matrix, significantly improving wear resistance, thermal crack resistance, and toughness compared to CrMo or CrMnMo cast steel rolls. For very deep grooves, pre-machining the groove before final heat treatment can yield a uniform hardness layer on the groove sidewall or bottom, greatly enhancing thermal cracking resistance and wear resistance. Chemical composition and properties of alloy cast steel rolls for roughing stands are shown in Table 1.

3.2 Intermediate Stands

The main task of intermediate stands is to further shape the workpiece and provide suitable specifications for the finishing stand. Rolls here must possess good thermal crack resistance and wear resistance. Due to the deep grooves, certain strength and toughness are also required.

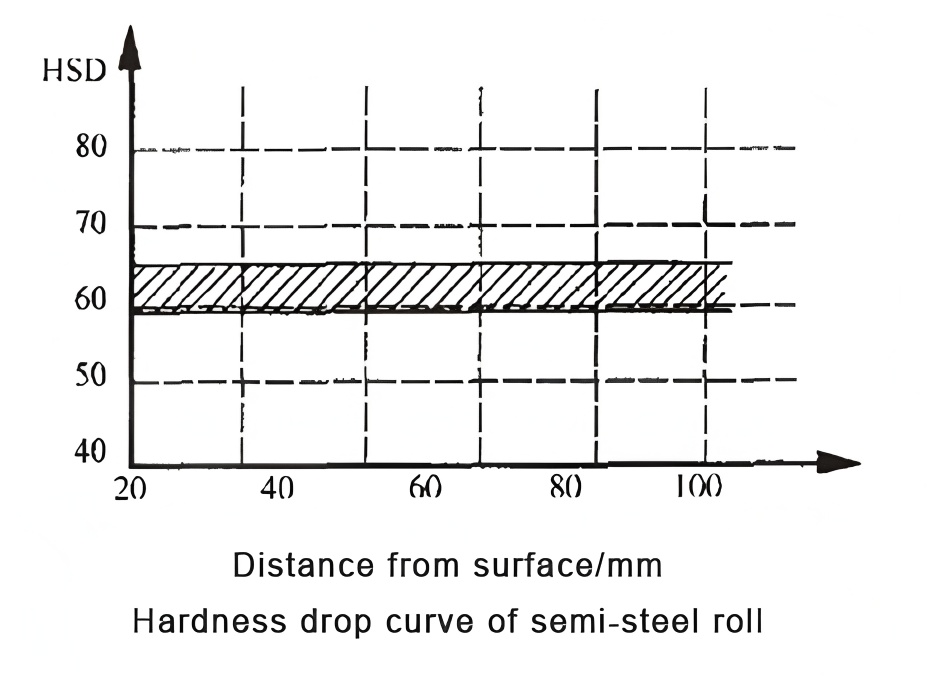

Before the 1980s, nodular semi-chilled cast iron rolls with a hardness of 40–45 HSD were commonly used in domestic mills. However, due to the sand-lined mold process, these rolls had low hardness, coarse structure, and unsatisfactory wear resistance and mechanical properties. Later, some manufacturers switched to CrMo and NiCrMo nodular infinite chilled cast iron rolls produced by cold spray coating, which refined the graphite, carbides, and matrix structure, improving wear resistance and overall mechanical properties. Nevertheless, for large sections with groove depths exceeding 100 mm, the chilling effect at the groove bottom is weak, and the matrix structure resembles that of nodular semi-chilled rolls, still lacking sufficient wear resistance for high-precision products. Alloy semi-steel rolls are recommended for such applications. With a carbon content between 1.3% and 2.3%, these rolls offer a balance of wear resistance, high strength, and good toughness. By adjusting composition and heat treatment, a fine pearlitic structure can be achieved. The hardness drop of semi-steel rolls is small—less than 2.5 HSD over 100 mm. Pre-machining the groove before final heat treatment can produce a uniform hardness layer, significantly improving thermal crack and wear resistance. Alloy semi-steel rolls require strict water cooling (typically, the groove surface temperature should be below 70°C after removal).

For rolls with simpler grooves, infinitely chilled or semi-chilled nodular cast iron grooved rolls may be used. Casting with grooves avoids excessive hardness drop during integral casting, thereby improving wear resistance.

For shallow grooves, pearlitic nodular iron rolls can be employed. These contain finely distributed graphite, which hinders the propagation of microcracks under alternating rolling stress, greatly enhancing thermal crack resistance and reducing demands on mill cooling water. Chemical composition and properties of alloy semi-steel and pearlitic nodular iron rolls for intermediate stands are shown in Table 2.

3.3 Finishing Stand

The finishing operation is critical for achieving negative tolerance rolling and improving dimensional accuracy. Rolls must therefore exhibit excellent wear resistance and thermal crack resistance, along with sufficient strength due to deep grooves.

For large section finishing stands, ordinary CrMo infinitely chilled cast iron rolls are often used, but they suffer from significant hardness drop, leading to low rolling capacity per groove, frequent groove and roll changes, increased roll consumption, reduced mill operating rate, and compromised product quality. High-carbon semi-steel rolls with carbon content above 1.9% are recommended. Alloying elements such as Ni, Cr, and Mo promote a bainitic or bainitic-martensitic structure, with slow hardness decline from surface to interior. Hardness is typically controlled at 50–60 HSD.

For mills with poor cooling conditions, graphite steel rolls are suitable. Developed from semi-steel, graphite steel forms spherical graphite in the matrix. Spherical graphite effectively prevents the initiation and expansion of thermal fatigue cracks. Alloying elements enhance matrix strength and toughness. Through controlled smelting, pouring, and heat treatment, fine pearlite with spherical graphite and hardened carbides is achieved, offering excellent thermal conductivity, lubrication, damping, crack resistance, and wear resistance. For deep grooves, secondary heat treatment after rough machining ensures uniform wear resistance at the groove bottom.

Depending on specific conditions, pearlitic alloy nodular iron rolls may also be used for finishing stands. The structure consists of pearlite + carbides + spherical graphite, or pearlite +少量 bainite + carbides + spherical graphite, with hardness of 55–65 HSD. Increased hardness improves wear resistance. Chemical composition and performance of graphite steel, semi-steel, and pearlitic rolls for finishing stands are compared in Table 3.

Conclusion

Based on the rolling conditions and required roll properties for each stand in large and medium section steel mills, the following principles should guide roll material selection:

Roughing stands: alloy cast steel rolls, hardness 35–45 HSD.

Intermediate stands: alloy semi-steel rolls, hardness 40–50 HSD; or alloy nodular iron rolls, hardness 45–60 HSD.

Finishing stands: high-carbon semi-steel rolls, hardness 45–55 HSD; graphite steel rolls, hardness 45–55 HSD; or pearlitic nodular iron rolls, hardness 55–65 HSD.