Keywords: rolling, temperature control

In hot working, the deformation termination temperature significantly influences steel microstructure. A higher termination temperature promotes grain coalescence and growth, resulting in coarser austenite grains. Therefore, the termination temperature should be minimized, though generally not below Ar3, to refine grains through controlled rolling and cooling, thereby improving product quality.

For low-carbon steel, the deformation termination temperature should be maintained near 800°C, and not below 750°C.

In high-carbon steel, to prevent the formation of network cementite, the deformation termination temperature should be controlled around 850°C. Proper matching of termination temperature with post-rolling rapid cooling can suppress proeutectoid cementite precipitation. Even if formed, it remains thin and easily eliminated without additional treatment.

In hypereutectoid carbon and alloy steels, excess cementite tends to form a carbide network along grain boundaries after rolling. This network reduces cold deformability and increases quench cracking susceptibility. Eliminating it requires complex heat treatment, which is not always effective. Thus, preventing its formation through appropriate rolling and cooling is essential. This can be achieved through rapid cooling after finishing and low-temperature rolling.

For instance, in GCr15 bearing steel, the temperature is reduced before final rolling. A water cooling unit is installed ahead of the finishing mill. After rolling, rapid cooling is applied using compressed air before transferring to a slow cooling pit.

Slow cooling after rolling produces coarse ferrite grains, lowering yield point and raising the brittle transition temperature. Cooling rate correlates with steel cross-section; larger sections cool slower, leading to inferior mechanical properties. Overseas, round steel is often air-cooled, benefiting from low gas content. Online water cooling is more effective for sections below Ф75mm, though longer water cooling lines increase investment. Rapid cooling helps reduce secondary banding, but with coarse austenite grains—especially in high-manganese steel—it may form Widmanstätten ferrite. Thus, rapid cooling should be paired with low deformation termination temperatures to avoid this.

For alloy structural steel rolled on medium mills, sections under Ø60mm are air-cooled, while larger sections are cooled in unheated slow cooling pits. Cooling to 100–150°C should take no less than 30 hours.

Bearing steel is prone to white spots, so it must be slowly cooled after rolling or heat-treated per specified regimes, with charging temperature not below 700°C. Billets are pit-cooled to below 100–200°C for an average of 72 hours. Even with low finishing temperatures, slow cooling can cause cementite networks. These do not form if cooling below 650°C is rapid. To avoid networks, each bar should be cooled individually and quickly below 650°C. The required cooling rate depends on the final rolling temperature: at 900–950°C, it should be no less than 45–50°C/min, decreasing with lower finishing temperatures.

Controlling the final finishing temperature (near Ac3) in the finishing mill, coupled with adequate reduction (~40%), yields ideal microstructures and mechanical properties in low- and medium-carbon steels, alloy steels, spring steels, bearing steels, and other medium-alloy steels. Water cooling boxes before the last two stands of the bar finishing mill, along with an equalizing section, ensure uniform temperature in rapidly cooled stock.

Cooling methods after rolling include:

Air cooling

Low thermal conductivity materials

Incubators

Unheated holding pits

Preheated holding pits or ovens

Heated holding pits or furnaces

Water cooling

Controlled Rolling and Cooling for Representative Steels:

Bearing and Spring Steels

Require low-temperature finishing and slow cooling after rolling. To prevent carbide precipitation, bearing steel should be rapidly cooled after rolling, then slowly cooled. The final rolling temperature is strictly controlled at 800–850°C to help break up carbide networks. If above 900°C, water spraying quickly cools the steel to 600–650°C, followed by slow cooling. A cooling water tank before the finishing mill controls entry temperature.

Quenched and Tempered Steel (Quenching + High-Temperature Tempering)

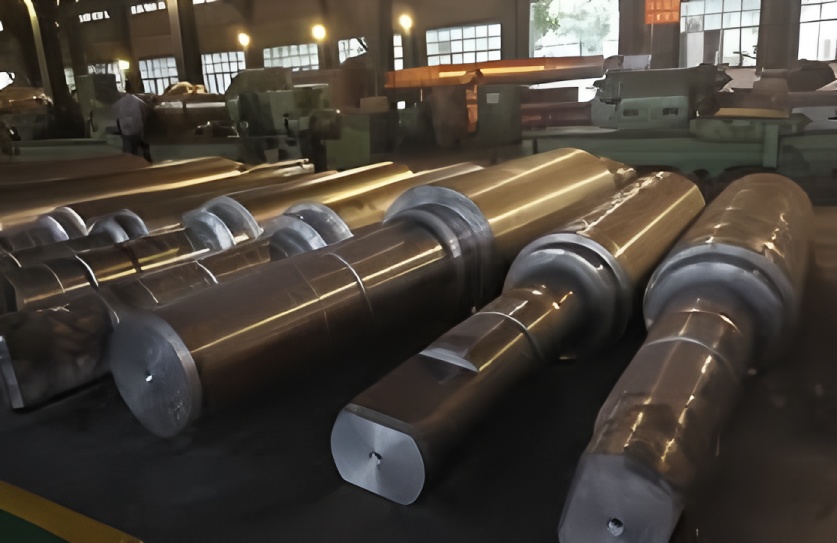

The structure is tempered sorbite, offering high strength, yield limit, ductility, and toughness—ideal for impact or alternating load components like connecting rods and shafts.

High-Quality Carbon and Alloy Structural Steels

Both are hypoeutectoid steels. The quenching temperature is 30–50°C above Ac3. For rounds under Ø40mm, a water cooling tank before the finishing mill refines grains to obtain martensite, which is then tempered to stable tempered microstructure.

Online temperature control for larger rounds (e.g., Ø20–Ø100mm) is implemented at plants like ABS LUNA in Udine, Italy, for carbon, surface-hardened, quenched and tempered, microalloy, bearing, spring, and stainless steels.

Given current market trends, supplying automotive-grade steel and moving upmarket is essential. Providing ideal microstructure and mechanical properties offers competitive advantage. For rounds under Ø40mm, water cooling boxes before and after the finishing mill help control online temperature.

Long-term, online temperature control should be considered, with water cooling after finishing to remove scale and improve surface quality. Heating, finishing, and cooling systems for various steels are summarized in Table 1:

| Steel | Heating Temperature (°C) | Cooling Method | Finishing Temperature (°C) |

|---|---|---|---|

| 45# | 1050–1180 | Air cooling | ≥850 |

| 40Cr | 1050–1180 | Air cooling | ≥850 |

| 20MnV, 40MnB, 20CrMo | 1050–1180 | Heap cooling | ≥850 |

| GCr15 | 1050–1100 | Pit cooling, entry ≥600°C | ≥850 |

| 20CrMnTi | 1050–1120 | Heap cooling (<Ø85mm), Pit cooling (≥Ø85mm), entry ≥600°C | ≥850 |

| 45Mn2, 27SiMn | 1050–1180 | Pit cooling, entry ≥400°C | ≥850 |

| 60Si2Mn | 1030–1120 | Pit cooling, entry ≥400°C | ≥850 |

Controlled Rolling Theory

Through controlled heating, deformation, and temperature systems, hot rolling combines solid-phase transformation with thermoplastic deformation to achieve fine grain structures and excellent comprehensive properties.

For mild and low-alloy steels, rolling parameters are controlled to refine deformed austenite grains. Transformation to ferrite and pearlite yields fine ferrite grains and relatively fine pearlite nodules, enhancing strength, toughness, and weldability.

For high-carbon and hypereutectoid steels, temperature-controlled rolling refines austenite grains, finishing near the transformation point.

Thermomechanical Rolling

Currently for rounds under Ø40mm, mainly low-carbon and low-alloy steels, aimed at refining ferrite grains. Finish rolling at 750–790°C, with water cooling before and after. For larger rounds, uneven surface-to-core cooling can cause small surface cracks and inconsistent grain size, leading to structural non-uniformity.

Normalized Rolling

For Ø40–Ø80 rounds, normalized rolling is used, with total deformation in the last four passes at 50–60%.

Temperature-Controlled Rolling

Final rolling at 850–900°C, with controlled cooling to improve surface quality. For high-carbon steel, fine pearlite nodules are obtained; for hypereutectoid steel, carbide network precipitation is reduced.

HANI employs normalized rolling for steels like 20#, 45#, 20CrMo, 20CrMnTi, 40Cr, and 40MnB for Ø50–Ø80 rounds, though isothermal holding before finishing increases process length and reduces output. Greater deformation in the last four passes is applied. A sizing mill ensures dimensional accuracy and uniform cross-section deformation but requires investment. For sizes above Ø80mm, temperature-controlled rolling is used. For spring flat steel, thermomechanical rolling in the ferrite-austenite two-phase region refines grains and improves strength and toughness, though water cooling before and after finishing increases investment and process length. Bearing steel requires temperature-controlled rolling to prevent carbide networks and improve surface quality.

From an investment and process standpoint, HANI adopts temperature-controlled rolling to lower initial temperatures, control finishing temperatures, and manage cooling for improved surface quality and internal structure.

Rolling Processes for Different Steel Grades and Specifications:

| Steel | Specification | Rolling Process |

|---|---|---|

| 20#, 45#, 20CrMo, | Ø50–Ø80 | Normalized rolling; Temperature-controlled rolling |

| 20CrMnTi, 40Cr, 40MnB | ||

| Ø80–Ø150 | Temperature-controlled rolling | |

| GCr15 | Ø50–Ø95 | Temperature-controlled rolling |

| 60Si2Mn | 14–20mm × 160–165mm | Thermomechanical rolling with water cooling; Temperature-controlled rolling |