Abstract: This article provides a concise overview of the casting and heat treatment processes for hot mill rolls, along with an analysis of common issues encountered during their use. High chromium cast iron rolls are widely employed in the front stands of hot-rolled wide strip finishing mills, as well as in certain small bar and section steel finishing mills. They are highly favored by users for their excellent wear resistance and resistance to surface spotting.

Classification and Material Selection of Metallurgical Mill Rolls

High Chromium Cast Iron Rolls

High chromium cast iron rolls have found extensive application as conventional rolls in hot strip mills, cold strip mills, wide and heavy plate mills, and small section and bar/wire mills, delivering significant economic benefits across various contexts. To enhance the thermal conductivity of these rolls, Japan has also developed high chromium cast iron rolls containing graphite within the working layer structure.

Beginning in the mid-1980s, several Chinese research institutes and manufacturers initiated the development of high chromium cast iron rolls. Large-scale rolls are now produced using vertical and horizontal centrifugal casting methods. These are utilized as work rolls in the front sections of both hot roughing and finishing mills in strip production, further expanding their varieties and range of applications.

Production Methods for High Chromium Cast Iron Rolls

Currently, nearly all high chromium cast iron rolls are manufactured via centrifugal casting, with horizontal, vertical, and inclined centrifuges being the main forms. Compared to earlier methods such as the “overflow method,” centrifugal casting enables rapid cooling of a thin shell of high chromium iron, resulting in a finer and more dispersed carbide structure, thereby improving production efficiency.

The roll core is typically made of high-strength nodular cast iron. Due to the high chromium content in the outer layer, the silicon and nickel content in the core must be appropriately increased compared to conventional rolls. This adjustment helps reduce carbide formation in the core structure and enhances core strength.

To prevent chromium from the outer layer from diffusing into the core during pouring, a transition layer is often introduced at an appropriate stage. Materials such as medium chromium cast iron, semi-steel, or gray cast iron may be used for this transition layer. Strict control over pouring time, temperature, and quantity of molten metal is essential.

Metallurgical Properties of High Chromium Cast Iron Rolls

In Fe-Cr-C alloys, when chromium content exceeds 15%, cementite becomes unstable and is replaced by the complex hexagonal M₇C₃ carbide. This chromium-rich carbide consists mainly of chromium and iron, often with traces of other alloying elements. A defining feature of high chromium cast iron roll material is that its eutectic carbide microstructure is dominated by (Cr, Fe)₇C₃, which has a microhardness of 1500–1800 HV, compared to 1000–1200 HV for cementite. This accounts for the superior wear resistance of these rolls.

The primary chemical composition (in %) of high chromium cast iron rolls is: C: 2.2–3.4, Cr: 10–25, Mo: 0.3–4, Ni: 0.3–3.0. The chromium-to-carbon ratio (Cr/C) determines the type of carbides present, while the contents of C, Cr, and Mo influence the volume fraction of carbides. Elements such as Ni and Mo serve to strengthen the matrix and enhance its hardenability.

Most research on the Fe-Cr-C alloy system is based on the corresponding ternary phase diagram.

Production Process

High chromium cast iron is typically melted in induction or electric arc furnaces, using raw materials such as pig iron, scrap steel, charge materials, ferrochromium, ferromolybdenum, and nickel. Controlling silicon content in pig iron and ferrochromium is critical. The influence of various alloying elements in the scrap on hardenability should remain stable. Ferrochromium is generally added during the later stages of melting to minimize oxidation loss.

High chromium cast iron rolls are formed via centrifugal casting. Key advantages of this process include improved molten metal and alloy yield, effective prevention of chromium diffusion into the core, assurance of core and neck strength and toughness, and excellent metallurgical bonding between the two materials. Europe and America commonly use two-material centrifugal composite casting, whereas Japan often employs a three-material approach.

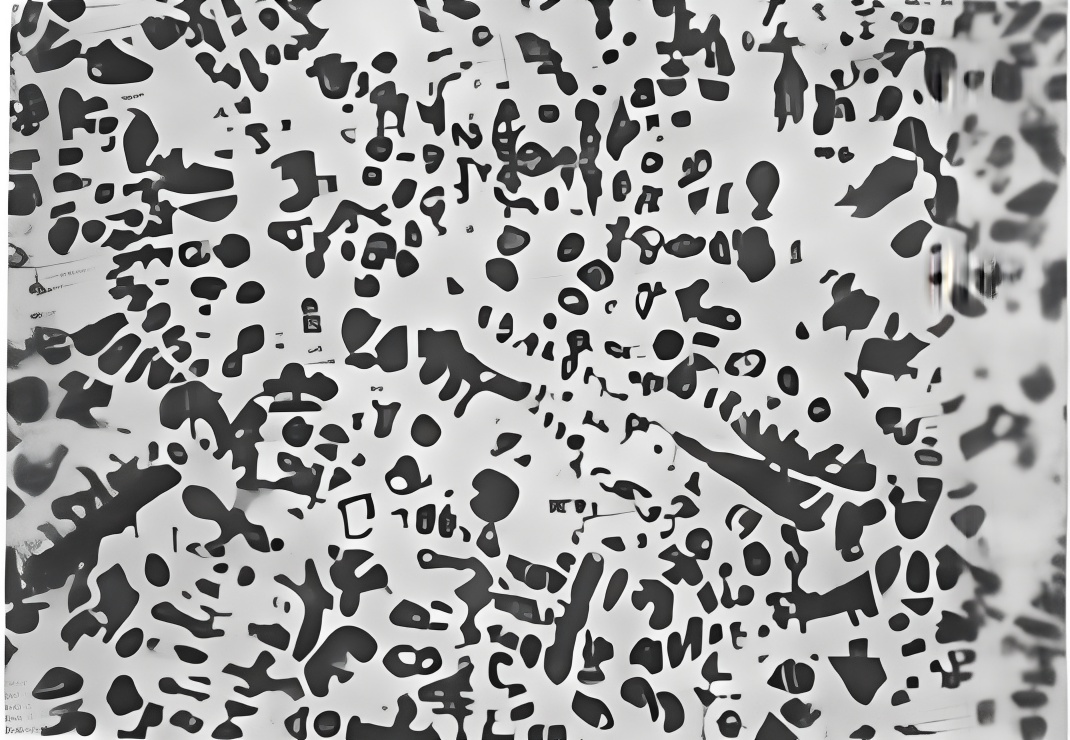

Heat treatment generally includes high-temperature austenitization, normalizing, and tempering. This process controls the retained austenite content in the working layer and achieves the desired matrix structure. Heating and cooling rates must be carefully managed to prevent cracking. A typical metallographic structure of the heat-treated outer layer is illustrated in the accompanying figure.

Performance and Applications

The (Cr, Fe)₇C₃ carbides in high chromium cast iron rolls are distributed discontinuously, unlike the continuous M₃C carbide network in conventional white cast iron. This structure imparts higher strength and toughness alongside exceptional wear resistance. The presence of isolated high-hardness carbides and the formation of a protective dense oxide layer during rolling—thanks to high oxidation resistance—contribute to this performance.

The high wear resistance and surface roughness retention not only extend service life but also improve the dimensional accuracy and surface quality of rolled products. For instance, when used in the front stands of hot strip mills, these rolls resist spotting defects, making them suitable replacements for indefinite chill cast iron and semi-steel rolls.

However, the relatively low thermal conductivity of high chromium cast iron necessitates sufficient water cooling during use to reduce thermal stress and prevent heat cracking. Additionally, machining, grinding, and surface roughening of these rolls are more challenging compared to conventional cast iron rolls.

By adjusting chemical composition and heat treatment, the carbide content and matrix structure can be tailored to produce rolls with varying hardness levels, broadly categorized as low-carbon, low-chromium types for accident resistance and high-carbon, high-chromium types for wear resistance. The table lists typical chemical compositions and application ranges for several common hardness grades.

High Chromium Cast Steel Rolls

These rolls use high chromium steel for the outer layer, with a nodular iron core and neck, produced via centrifugal composite casting. The primary carbides are mainly (Cr, Fe)₇C₃. Typical chemical composition (%) is: C: 0.7–1.4, Cr: 6–15, Mo: 0.5–3.0, Ni: 0.3–2.0.

High chromium cast steel rolls represent another advancement following high chromium cast iron rolls. First trial-produced in Europe in the early 1980s via centrifugal casting, they are now widely used in hot strip mill roughing stands globally.

Production Process

High chromium cast steel is generally melted in electric arc furnaces due to its high melting point, using raw materials similar to those for cast iron rolls. The nodular iron core requires specialized treatment to ensure good graphite nodulization in large sections. Centrifugal casting offers benefits akin to those for cast iron rolls.

High chromium cast steel, being a hypereutectoid Cr-Mo steel, has a wide solidification range. Centrifugal casting promotes rapid solidification under centrifugal force, reducing defects, segregation, and grain size. Producing defect-free rolls with a sound bonding layer demands scientifically determined process parameters and strict control.

In the as-cast state, high chromium cast steel is relatively soft and machinable but requires heat treatment, typically normalizing or spray quenching and tempering. The resulting microstructure consists of primary (Cr, Fe)₇C₃ carbides, tempered martensite, finely dispersed secondary carbides, and some retained austenite. Heat treatment induces beneficial circumferential compressive stresses, enhancing resistance to thermal fatigue cracking.

Material Characteristics

With lower carbon content, high chromium cast steel contains fewer primary carbides (generally <10%), leading to higher yield strength, toughness, and improved surface roughness resistance than cast iron. Better thermal conductivity also enhances thermal crack and accident resistance. Consequently, cooling requirements are less stringent, and rolling bite performance is improved—an issue often encountered with cast iron rolls in roughing stands.

Higher Cr/C ratio and matrix chromium content grant superior oxidation resistance. The dense oxide film formed during rolling ensures high wear resistance, extends service life, and boosts productivity.

Both the high chromium steel outer layer and nodular iron core have high elastic modulus, resulting in much lower elastic deformation during rolling compared to indefinite chill cast iron rolls. Some countries have trialed these rolls as work rolls in cold strip mills and hot strip finishing stands.