Abstract

With the advancement of rolling technology and mill equipment, coupled with increasing quality requirements for rolled products and the application of semi-high-speed steel (SHS) and high-speed steel (HSS) work rolls (or intermediate rolls), the performance demands on backup rolls (BUR) have become more stringent. This paper reviews the current status of backup roll manufacturing technology and analyzes development trends in materials, melting, and heat treatment processes. To meet the diverse needs of various mills and products, functionally customized backup rolls are becoming an inevitable choice. Key future directions include higher alloy content designs, electroslag remelting (ESR), and advanced induction heating processes.

1 Introduction

The backup roll is a core component of rolling mills, directly influencing mill stability, production line continuity, consumption rates, and product quality 47. In recent years, growing demand for strip products has driven continuous improvements in mill equipment, rolling technology, and roll manufacturing. The widespread adoption of SHS and HSS work rolls (or intermediate rolls) in cold and hot rolling mills—with their significantly enhanced microstructure, hardness, strength, and wear resistance—has raised performance expectations for backup rolls. The development and application of large-scale electroslag remelting and integral induction heating equipment have created opportunities for innovation in the materials, melting, and heat treatment technologies of large forged steel backup rolls.

2 Performance Characteristics and Service Requirements of Backup Rolls

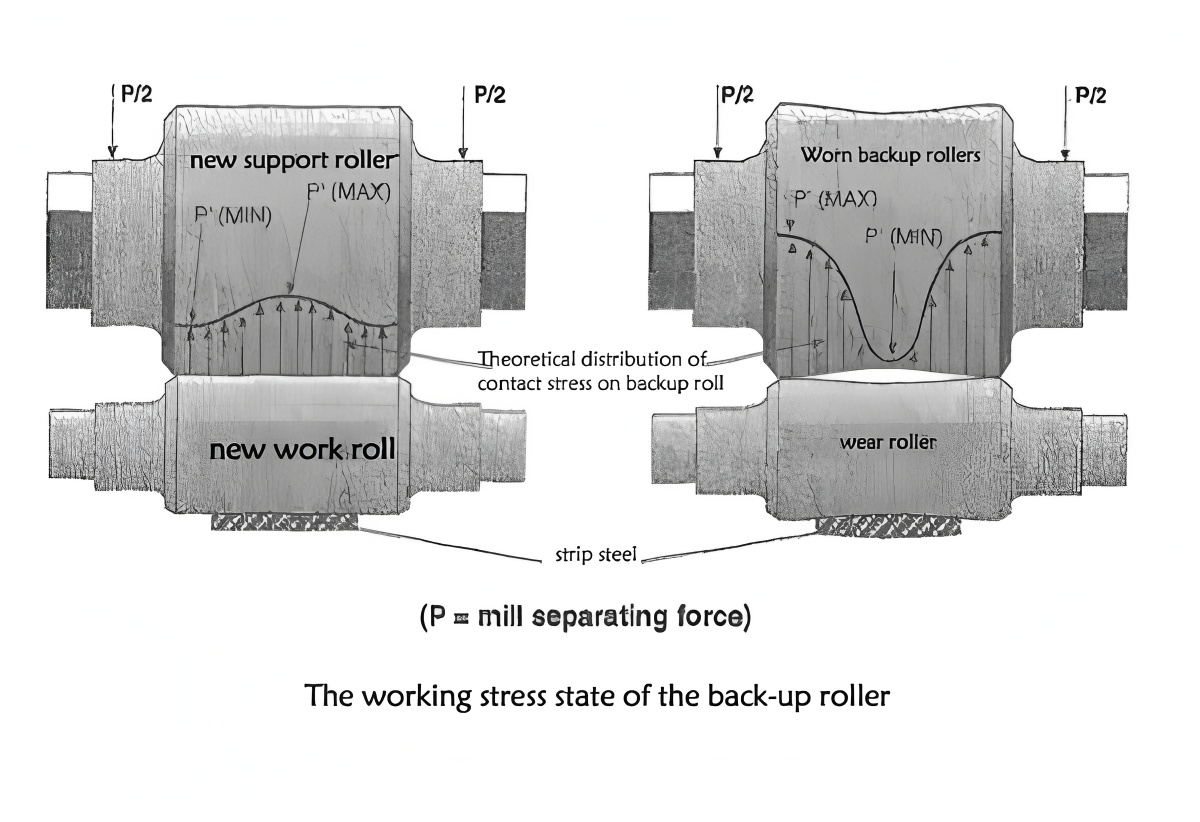

As a critical rolling mill component, the backup roll bears the entire rolling force, requiring high strength and rigidity. It remains in prolonged rolling contact with work rolls (or intermediate rolls), necessitating a roll surface with excellent wear resistance, contact fatigue resistance, and accident resistance (e.g., to impact, scratching, or crack propagation) 47. Simultaneously, the roll neck and body endure cyclic alternating bending stresses, demanding high strength, toughness, and fatigue resistance. Wear resistance and accident resistance are among the most critical performance indicators.

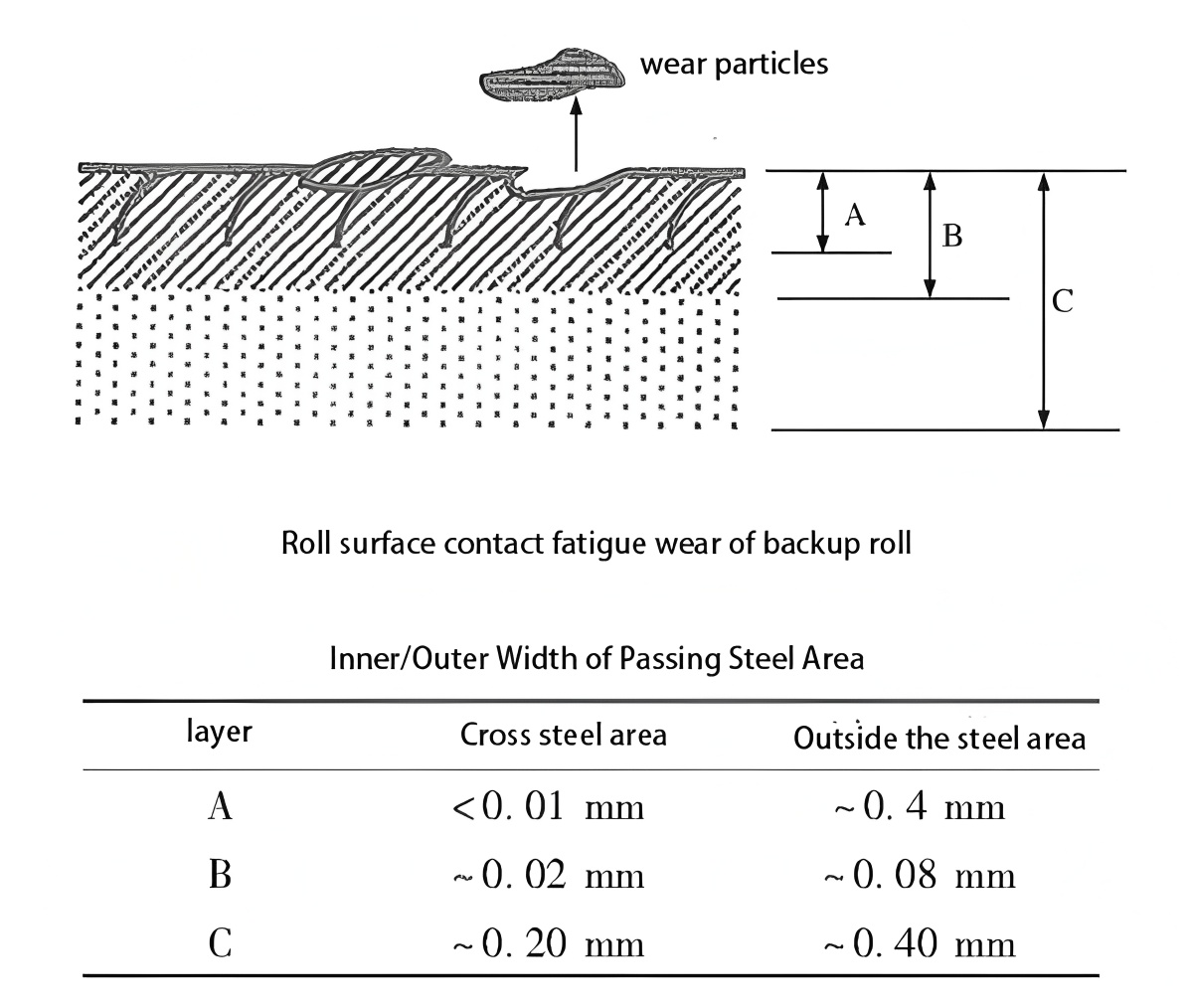

The wear process of a backup roll surface typically involves: rolling contact → fatigue → micro-crack generation → crack propagation → minor spalling. Wear patterns vary across mills: in the strip contact area of early stands of cold tandem mills, backup rolls often develop a “box-type” roll profile; in later stands, influenced by work roll bending, they are prone to “edge drop” wear; in cold rolling mills, roughened work rolls can cause severe wear across the entire backup roll surface; in hot rolling mills, the alternating action of high temperatures and cooling water creates an oxidative and corrosive environment, making backup roll wear more complex. Common backup roll failures include localized wear, roll surface indentation, spalling, and fracture. Accident resistance primarily refers to capabilities against intrusion, scratching, contact fatigue, and crack propagation, which are closely related to the material’s matrix strength and fracture toughness.

3 Development of Materials for Forged Steel Backup Rolls

Early backup roll materials were primarily 2% Cr series (e.g., 9Cr2Mo) and 3% Cr series (e.g., 70Cr3Mo, 50Cr3MoV, 40Cr3MoV). The 1980s saw the development of 4% Cr and 5% Cr forged steel backup roll materials. The overarching design philosophy has been to increase alloy content (e.g., Cr, Mo) and reduce carbon content.

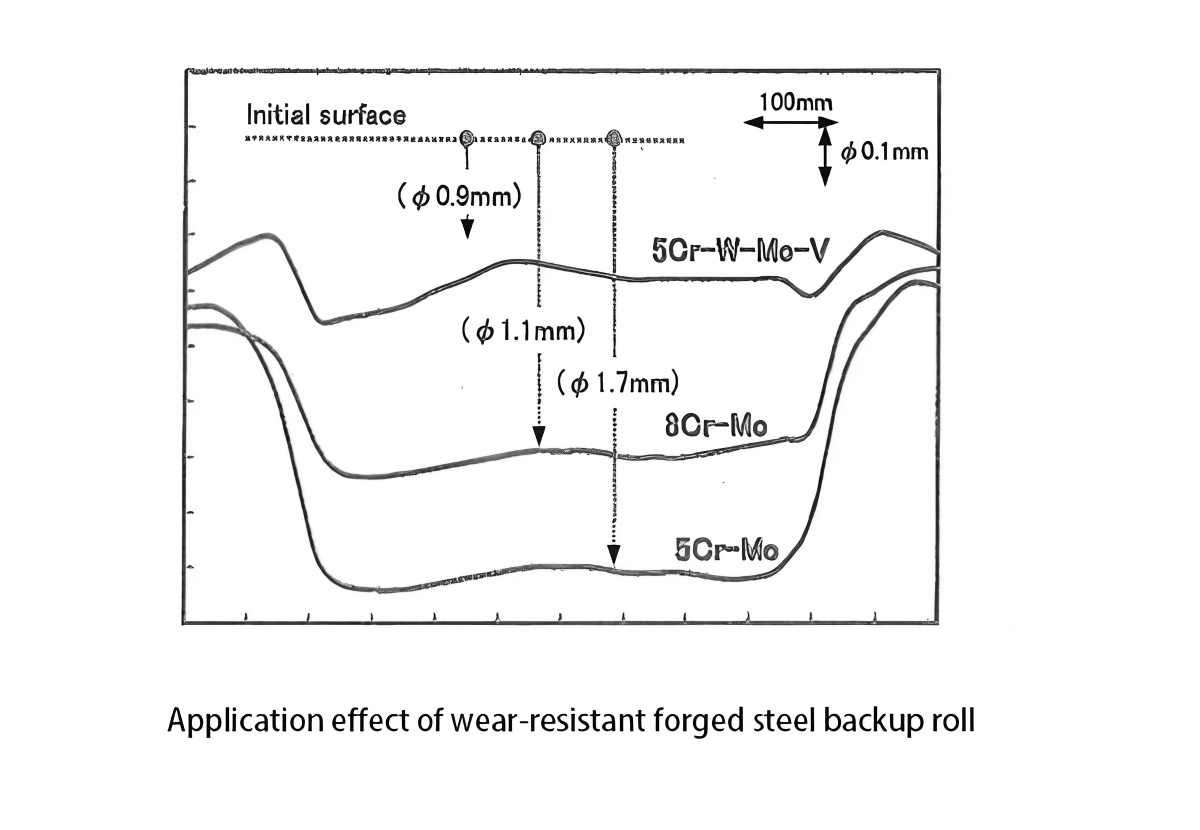

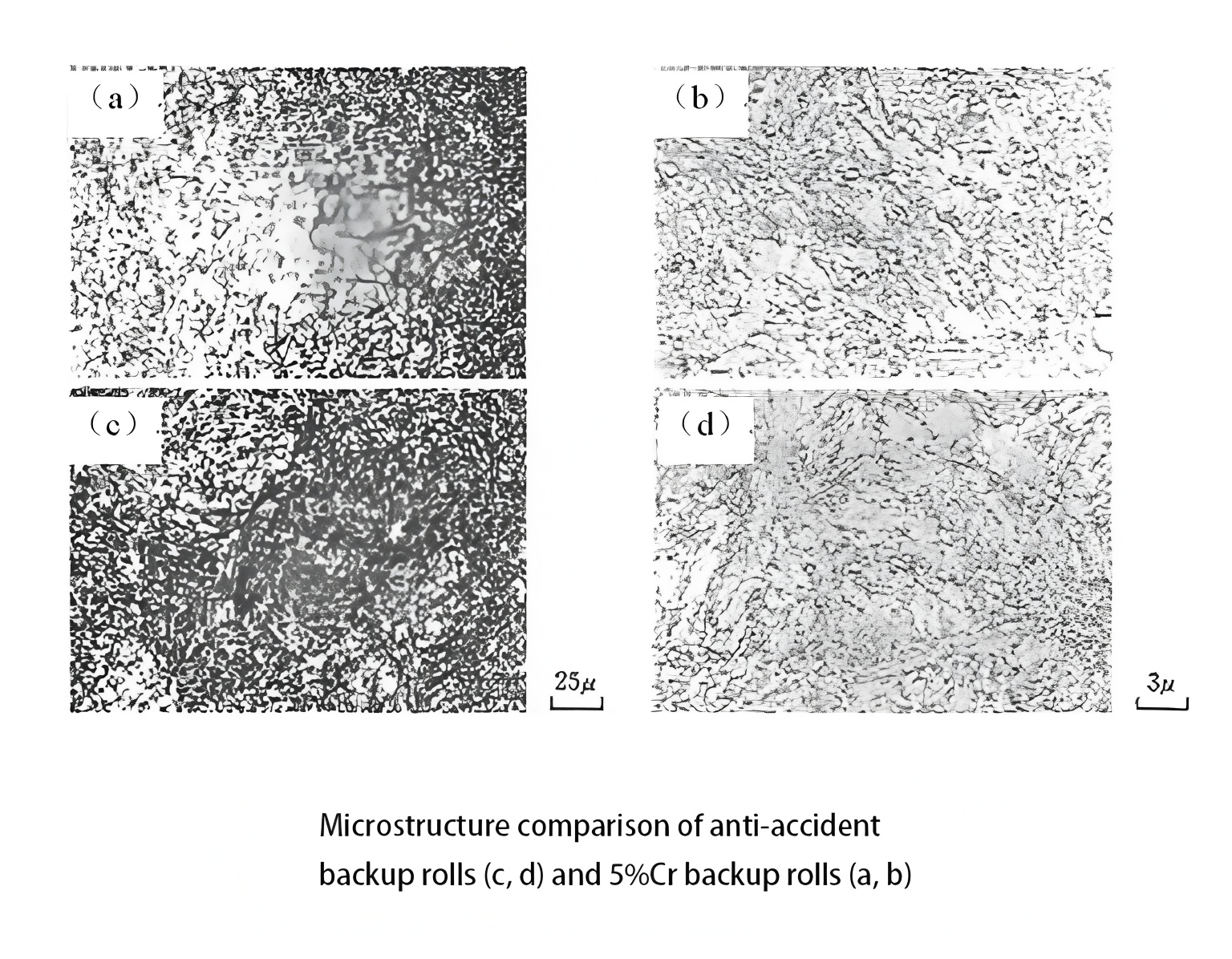

Currently, 5% Cr series forged steel backup rolls are widely used in large strip mills. These typically contain 0.4%–0.6% C and 4%–5% Cr, offering good hardenability and wear resistance. Their microstructure consists of granular MₓC₃ carbides dispersed on a tempered bainite matrix. The roll surface hardness reaches approximately 70 HSD, with a working layer depth exceeding 70 mm. Adding vanadium (V) refines grains and enhances core strength and toughness. To improve wear resistance, some manufacturers have developed modified 5% Cr and 8% Cr materials by increasing Mo, W, V, or Cr content. The microstructure of these forged steel backup rolls comprises tempered martensite/bainite matrices with composite carbides (MₓC₃, M₂C, MC), which have demonstrated effective application results.

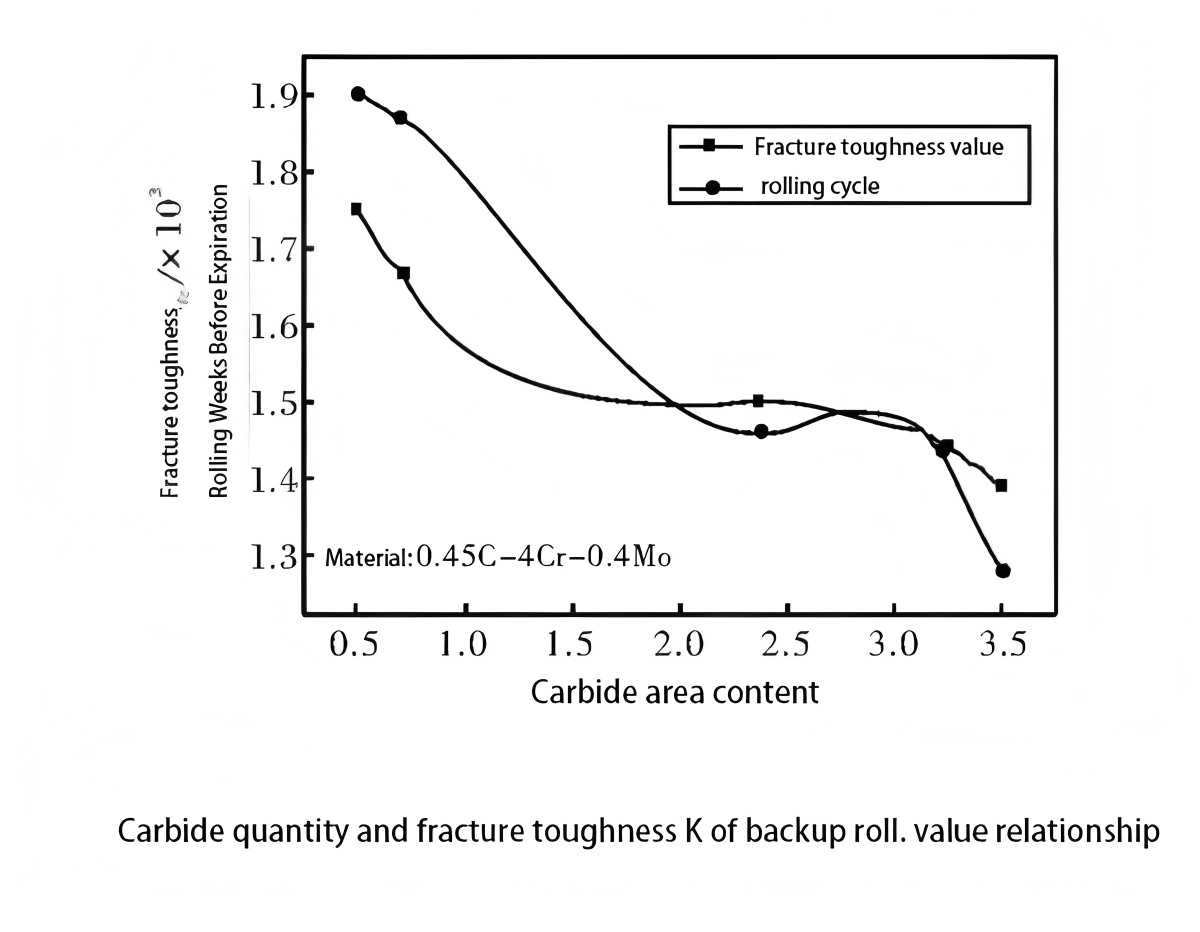

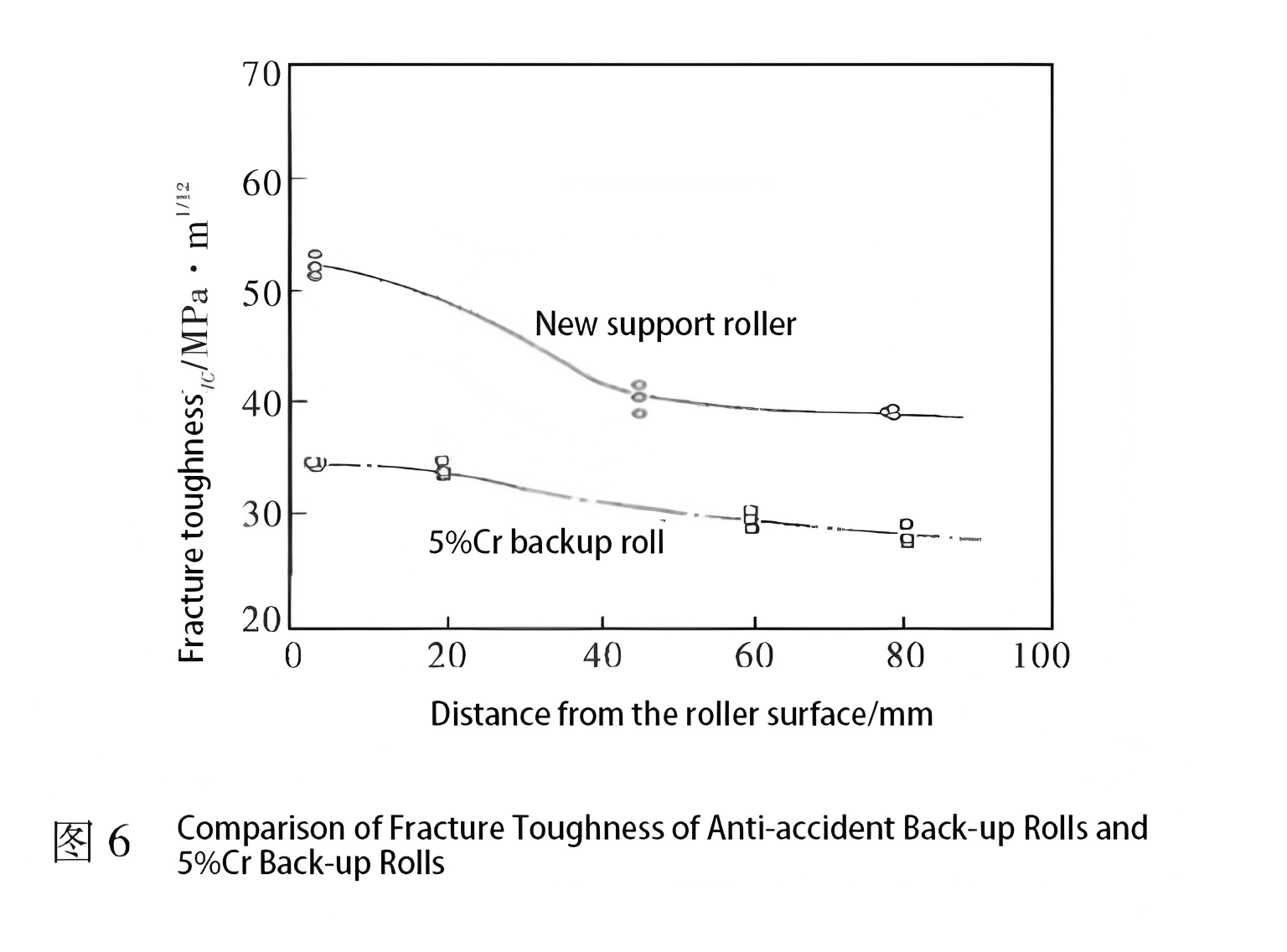

Research indicates a correlation between the fracture toughness (KIC) of backup roll materials and their contact fatigue cycles. Increasing fracture toughness extends service life, which can be achieved by reducing the carbide count in the microstructure. To enhance accident resistance, some manufacturers have developed accident-resistant forged steel backup rolls by reducing Cr, Mo, and V (main carbide-forming elements) while increasing Si and Mn content. This promotes solid solution strengthening of the matrix, improving fracture toughness.

However, trade-offs exist between different backup roll properties (e.g., strength vs. toughness). Thus, future material development will focus on ensuring comprehensive performance while enabling functional and personalized customization to meet diverse mill and product needs.

4 Advancements in Smelting Technology for Forged Steel Backup Roll Blanks

The primary manufacturing process for forged steel backup roll blanks is: electric furnace melting → ladle refining → vacuum degassing → (vacuum) ingot casting → forging → post-forging heat treatment → rough machining → ultrasonic testing → forged blank.

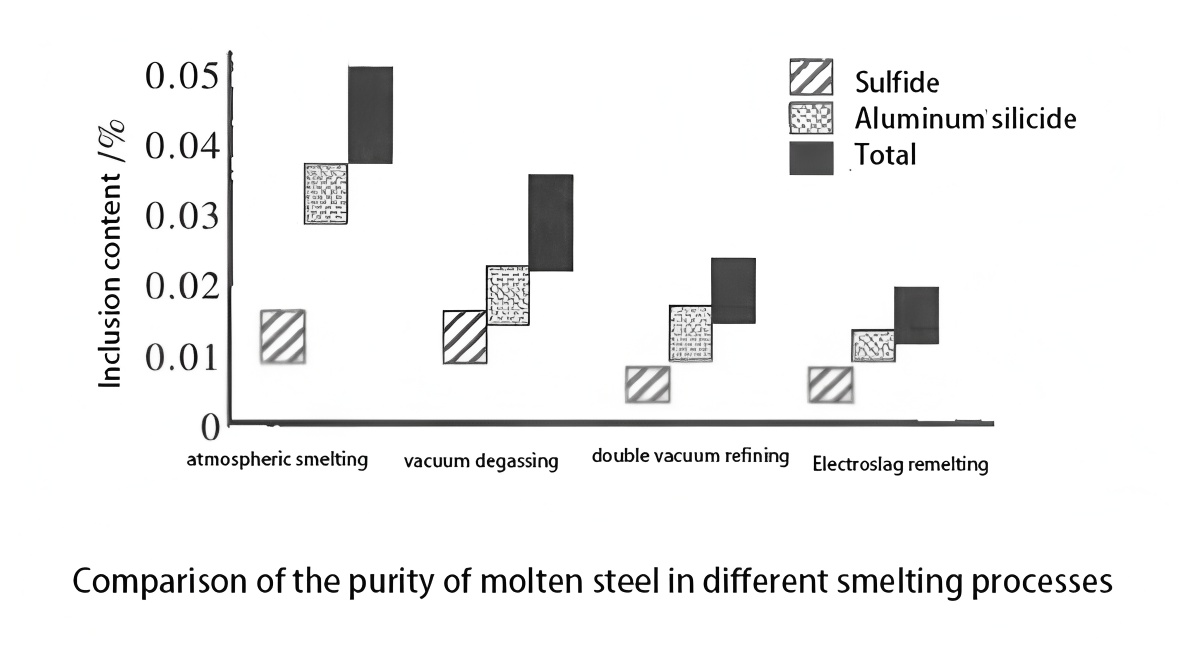

Due to their large size and heavy tonnage, large forged steel backup roll blanks are prone to casting defects. Their smelting process is complex, representing the pinnacle of large casting and forging technology. The double vacuum treatment process (vacuum degassing + vacuum pouring), emerging in the 1990s, improves molten steel purity by minimizing H, O, N gas content and reducing inclusions. It also enhances ingot segregation, crystallization state, and effectively controls the billet’s chemical composition, macro/microstructure, and inclusions.

Compared to traditional refining, the electroslag remelting (ESR) process offers distinct advantages:

High Molten Steel Purity: Under electroslag action, large non-metallic inclusions are removed, with excellent desulfurization and deoxidation capabilities, resulting in better plasticity and toughness than other melting methods.

Low Ingot Segregation: Molten steel solidifies in a water-cooled crystallizer with rapid cooling, reducing compositional segregation. Solidification proceeds sequentially from bottom to top, yielding a uniform structure free from porosity and shrinkage cavities.

High Ingot Utilization Rate: Typically reaching 85%–90%, with advantages becoming more pronounced for larger forgings.

However, ESR technology faces challenges in manufacturing large backup roll blanks, including equipment size limitations, slag composition variability, hydrogen control, and deoxidation issues. Consequently, large forged steel backup rolls produced via ESR have not yet demonstrated practical performance. Recent advancements in large-scale ESR technology and equipment are poised to make ESR-fabricated large backup roll blanks a reality.

5 Evolution of Heat Treatment Processes for Forged Steel Backup Rolls

The main heat treatment and processing sequence for forged steel backup rolls is: preliminary heat treatment of forged blank → semi-finishing → final heat treatment → finishing → ultrasonic testing → finished product.

Preliminary heat treatment (e.g., high-temperature normalizing, quenching, and tempering) ensures mechanical properties of the roll neck and body, adjusts the microstructure, and prepares the roll for final heat treatment. Quenching and tempering impart higher strength and toughness, particularly fracture toughness.

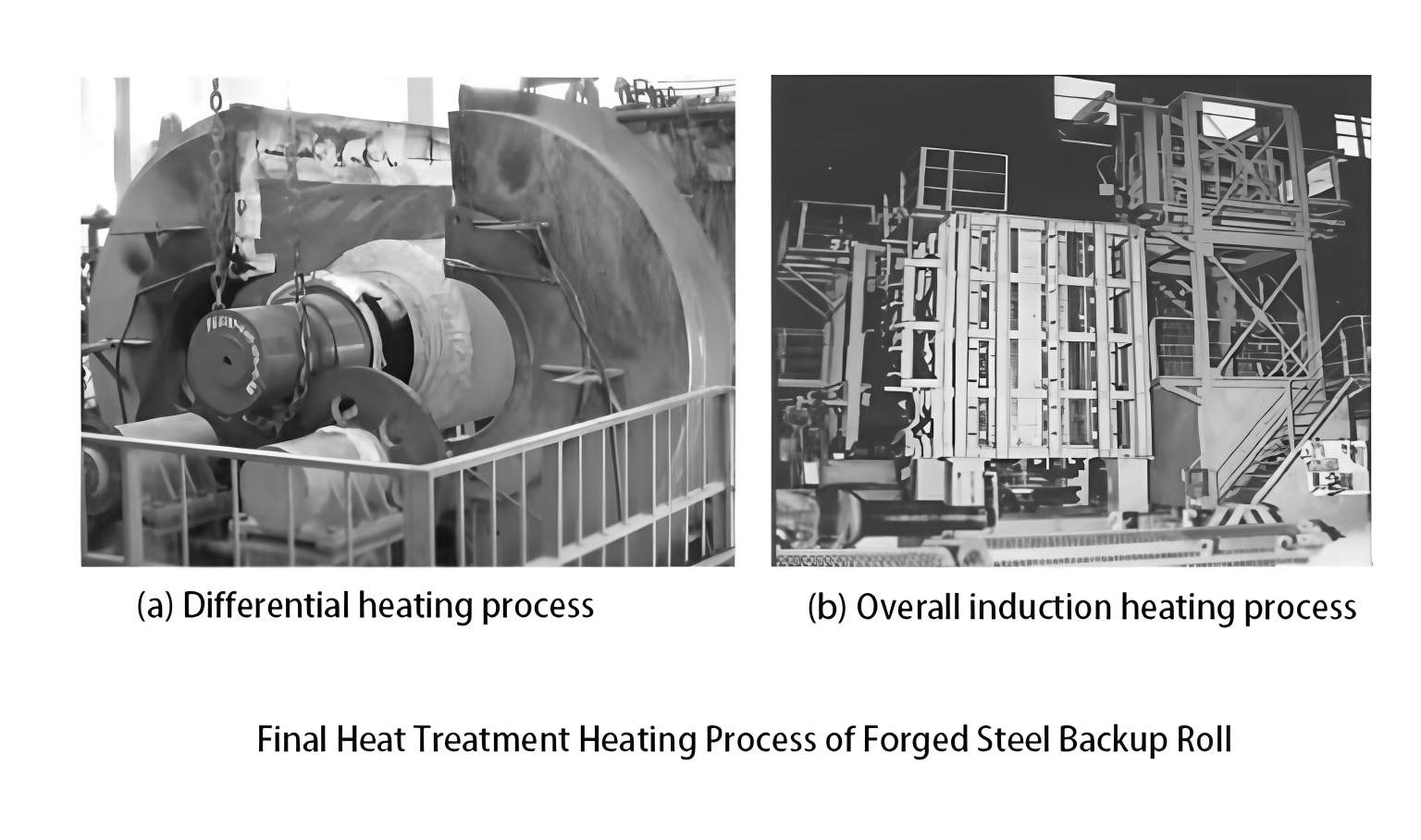

Final heat treatment (e.g., surface quenching and tempering of the roll body) is the critical process determining the backup roll’s working layer microstructure, hardness distribution, stress state, and performance. It represents the core of backup roll manufacturing technology. Heating methods typically include differential temperature heating or integral induction heating, while quenching mediums commonly involve spray cooling or oil cooling.

The differential temperature heating process uses high-velocity burners to rapidly heat the roll body surface, austenitizing it to a certain depth while the core remains below the phase transition temperature. This is followed by quenching, enabling deep surface heat treatment.

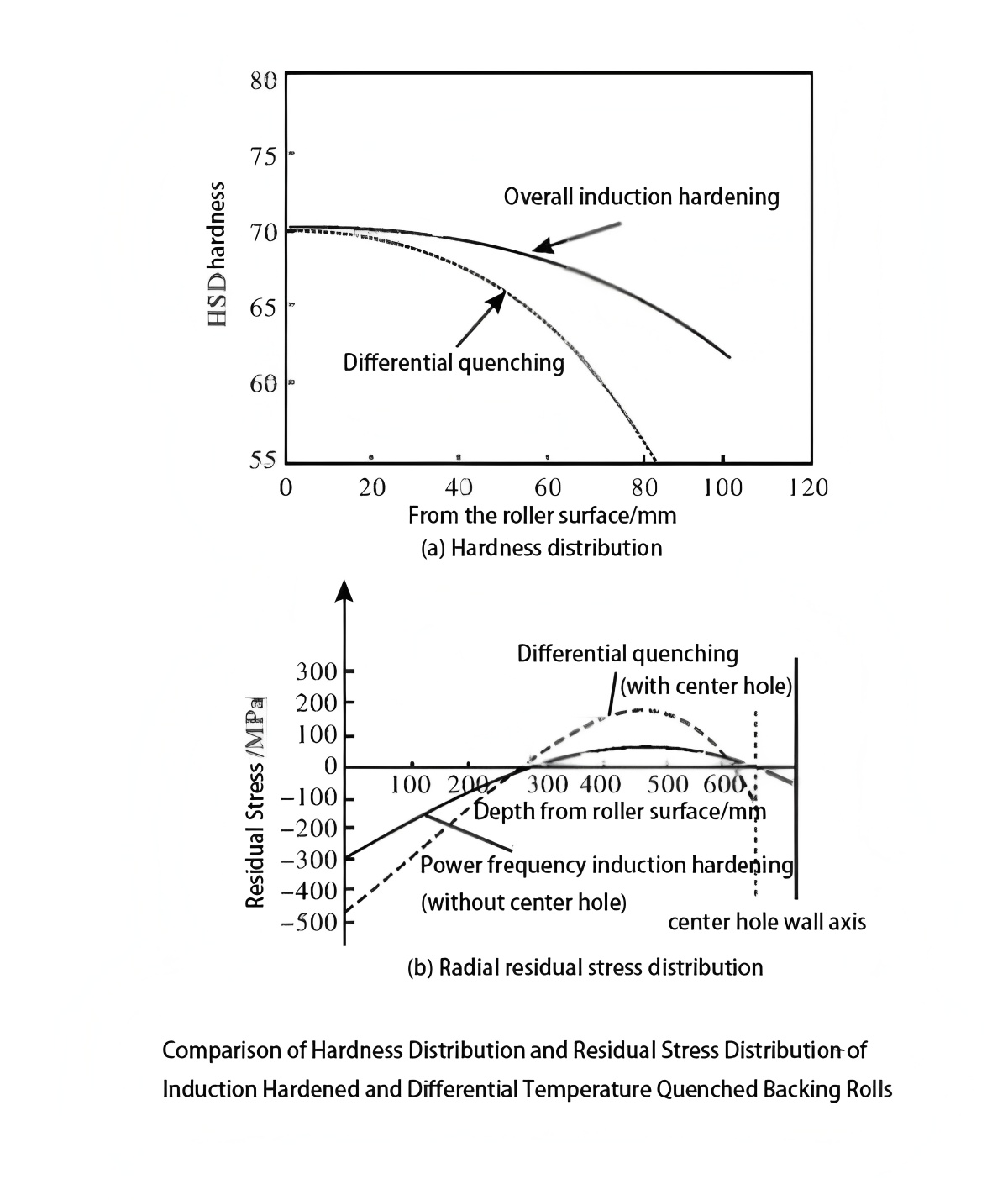

Currently, most backup rolls are produced via differential temperature heating and quenching. In the 1980s, Hitachi pioneered the power frequency integral induction heating process, later adopted by Japanese Cast & Forged Steel, Kanto Special Steel, and Nippon Steel. This process features short heating times, uniform temperature distribution, and deep heating penetration. Compared to differentially quenched backup rolls, induction-quenched rolls exhibit improvements in hardened layer depth, hardness gradient distribution, and radial residual stress distribution.

The surface hardness of differentially quenched backup rolls typically reaches 70 HSD, with a microstructure primarily of tempered bainite. In contrast, integral induction-hardened backup rolls can achieve surface hardness exceeding 75 HSD, with a microstructure dominated by tempered martensite, significantly enhancing wear resistance. Thus, integral induction-hardened backup rolls have become essential for producing high-quality steel strips in the metallurgical industry.

Recent research highlights the application of low-frequency integral induction quenching technology for large backup rolls. This involves developing locally integrated induction quenching equipment based on the one-shot method principle, utilizing high-power low-frequency (4 MW/25 Hz) digital power supplies and multi-tap variable-turn induction coils. These innovations ensure roll body surface temperature field uniformity ≤ ±5°C. Coupled with multi-furnace engineering temperature field tests, simulation technology for large backup roll induction heating has been successfully developed, covering nearly 70 specifications (e.g., φ1000mm–φ1650mm × 1200mm–2400mm). Industrial applications confirm that this independently developed technology achieves “roll body hardness uniformity Δ≤±1 HSD” and “zero hardness drop at 100 mm radial depth in the working layer,” reaching international top-tier hardness quality 7.

Additionally, research on large Cr5 forged steel backup rolls has focused on developing manufacturing technology without hardness drop. Through optimization of differential temperature furnace equipment and combining numerical simulation with experimental temperature measurement, the differential heat treatment process has been refined. Trial production and testing confirmed the achievement of “no hardness drop” in the working layer 10.

6 Future Development Trends

Functional and Customized Design: Backup rolls will increasingly be tailored to specific mill types, product mixes, and process conditions. This includes developing high-wear-resistance, high-accident-resistance, or comprehensive-performance grades 4.

Advanced Smelting Processes: Large-scale electroslag remelting (ESR) technology is expected to overcome current limitations, producing ultra-high-purity, homogeneous backup roll blanks that enhance overall performance and longevity 410.

Advanced Heat Treatment Technologies: Integral induction hardening will become more prevalent, leveraging its advantages in achieving deeper hardened layers, superior hardness profiles, and minimized residual stresses. Further developments in process simulation and precision control (e.g., AI-powered parameter optimization) will improve consistency and quality 47.

Integration of AI and Digitalization: Artificial intelligence will transform backup roll production and maintenance. AI can optimize material composition, forging parameters, and heat treatment processes, reducing waste and energy consumption. In operational settings, AI-driven predictive maintenance models, analyzing real-time sensor data from rolling mills, will anticipate wear or failures, minimizing downtime and ensuring consistent product quality 4.

Lightweight and High-Strength Materials: Responding to trends in end-use industries (e.g., automotive, aerospace), there will be a push towards developing lighter yet stronger backup roll materials without compromising performance 4.

Sustainability and Efficiency: Emphasis on resource-efficient production and sustainable practices will grow, driven by environmental regulations and cost pressures. This includes reducing energy consumption during manufacturing and extending service life to decrease the environmental footprint per ton of rolled product 4.

7 Conclusion

Wear resistance, contact fatigue resistance, and accident resistance remain the most critical performance indicators for backup rolls.

Functional and personalized material design for forged steel backup rolls is essential to meet the diverse needs of different rolling mills and products.

The electroslag remelting (ESR) process and integral induction hardening technology are key to producing high-performance backup roll products. They represent crucial directions for future manufacturing technology development and warrant further in-depth research and application.

The integration of AI and digital technologies throughout the product lifecycle—from design and manufacturing to in-service monitoring and maintenance—will be a major driver of innovation, efficiency, and reliability in the backup roll industry 47.