Common Faults and Handling Methods for Rolling Mill Roll Change Systems

The automatic roll change process for the finishing mill is divided into four stages:

Pre-change preparation stage

Pre-change equipment shutdown stage

Roll change execution stage

Post-change equipment recovery stage

Pre-change Preparation Process:

The roll change trolley moves the new roll from the initial position E1 (roll storage) to the roll change transfer cover (E7) in front of the finishing mill (the transfer cover is located on the flying shear side);

The roll change trolley returns to position E6, and the transfer cover moves to the colier side;

The roll change trolley advances to position E11.

Pre-change Shutdown Process (switch to roll change mode):

The mill has finished discharging the strip;

All mill cooling water is shut off;

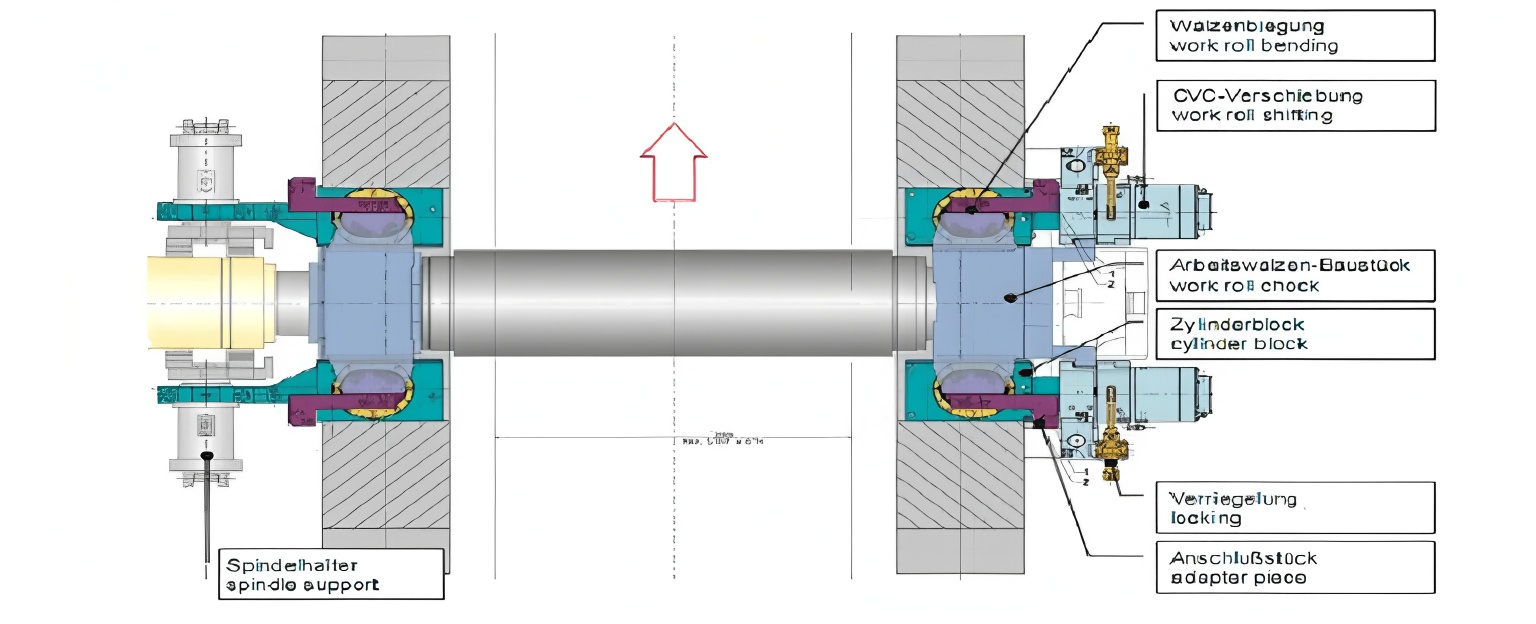

The CVC system moves to the roll change position;

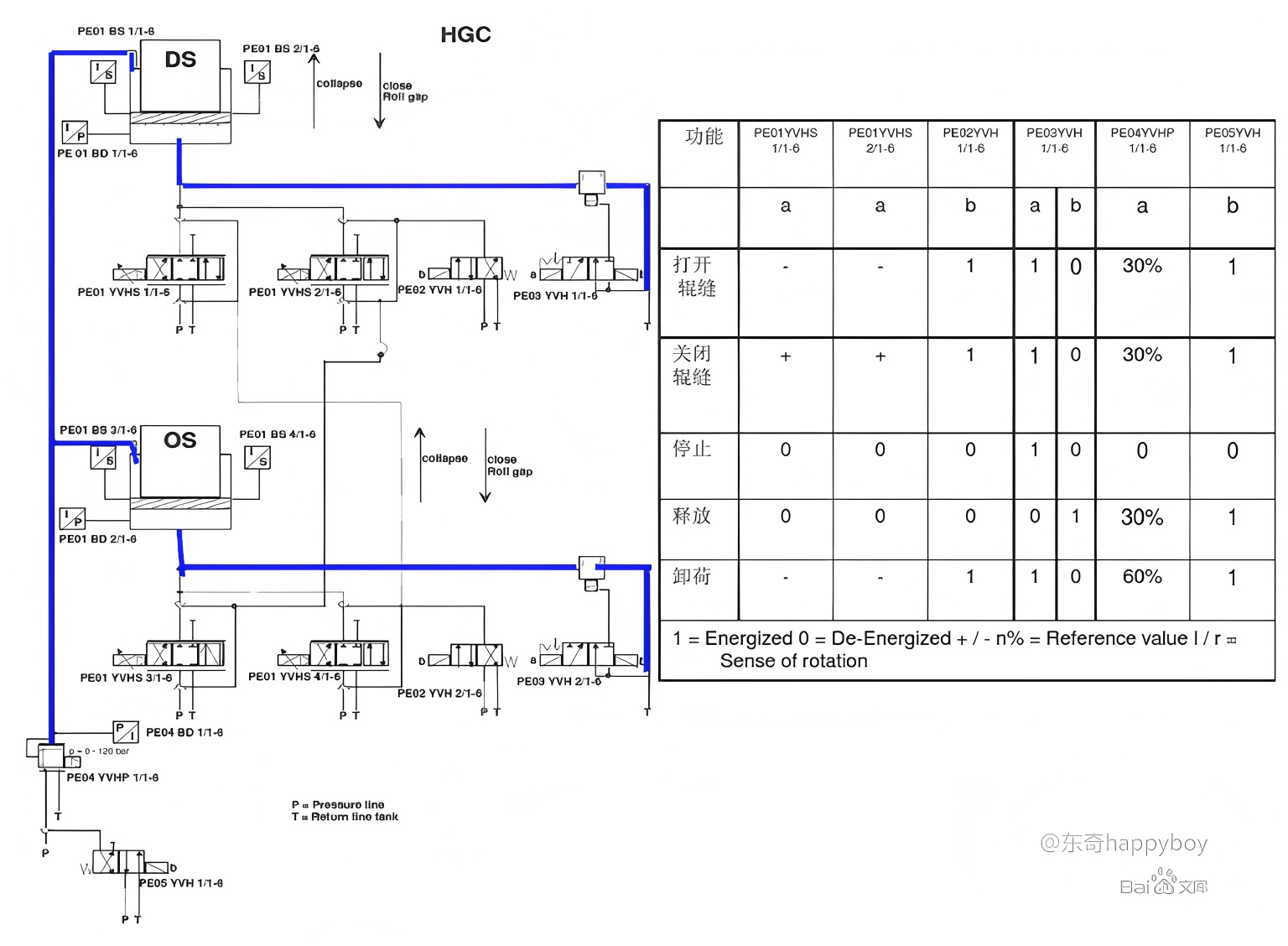

The AGC system is in the unload position;

Spindle positioning is completed;

The main drive is stopped;

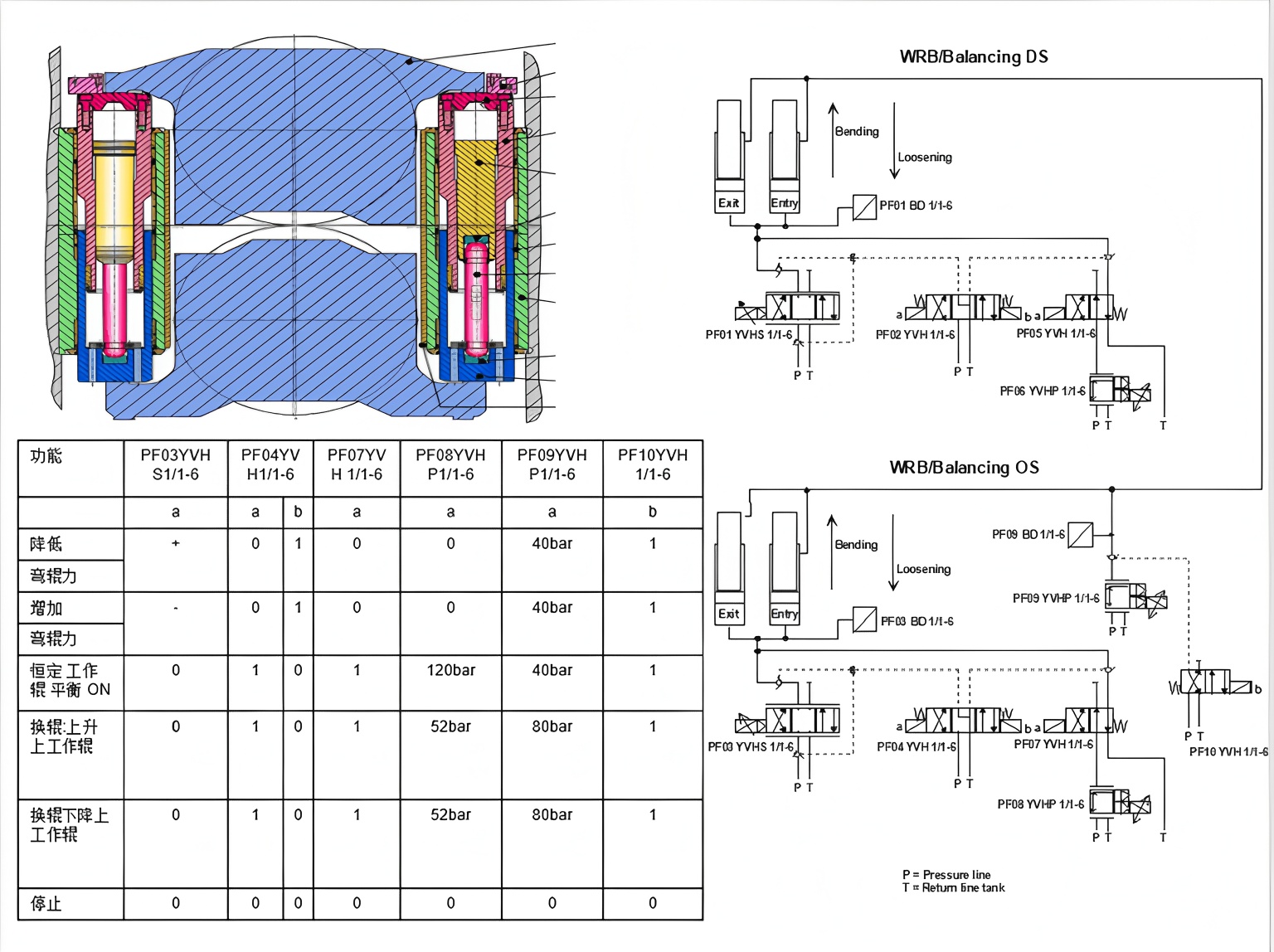

Work roll balance (WR) is switched to constant pressure mode.

Roll Change and Extraction Stage:

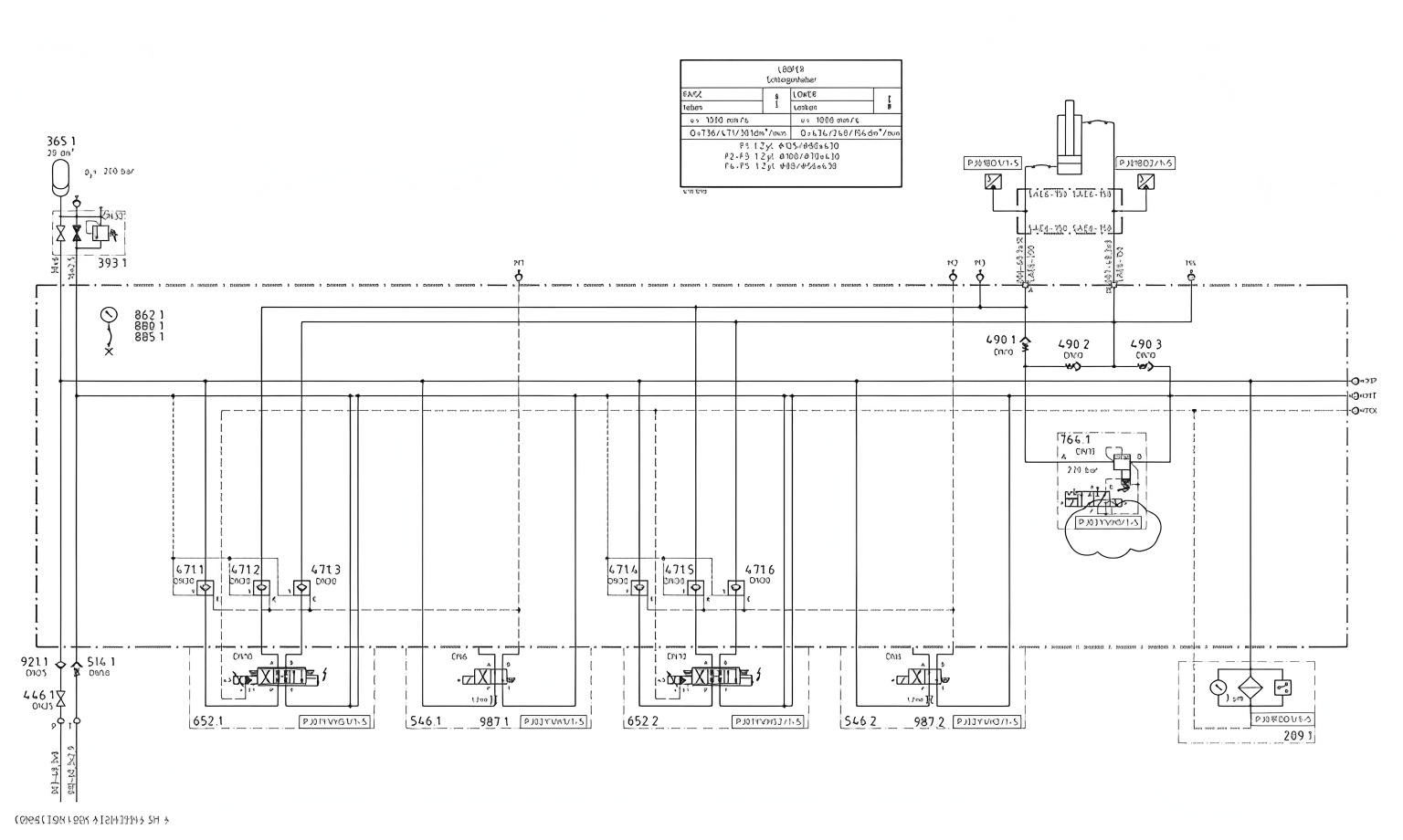

The looper is raised;

Entry and exit guides are retracted;

Entry and exit roll wipers are retracted;

Step plates move to the roll change position;

WR pressure is reduced to minimum;

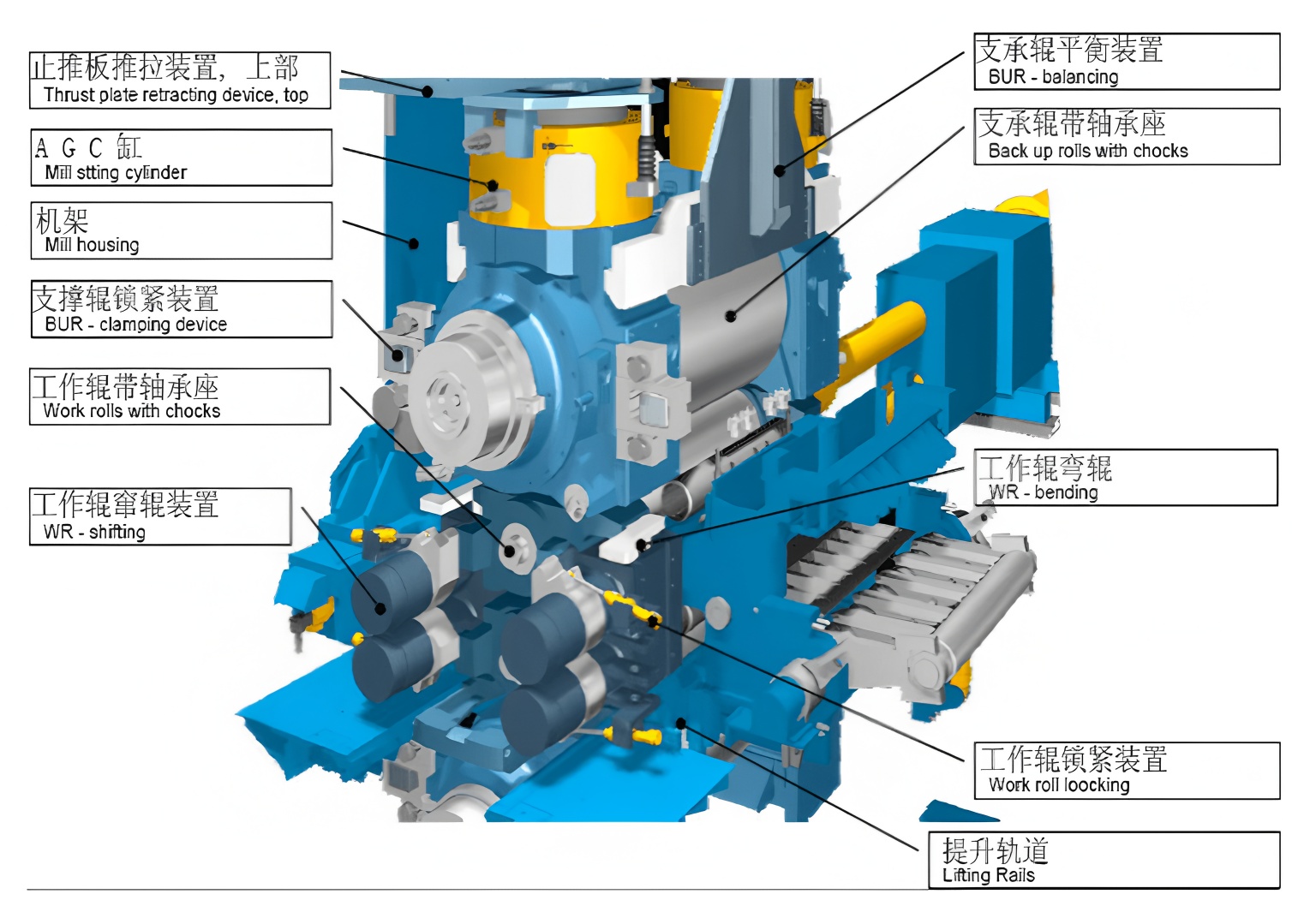

Lifting tracks are raised;

The roll change trolley moves from E11 to E13, and the hook lowers;

Lower spindle supports are closed;

Lower WR locking flaps are opened;

The roll change trolley moves from E13 to E12;

The upper work roll is lowered;

Upper spindle supports are closed;

Upper WR locking flaps are opened;

The roll change trolley pulls the work roll out to frame E7.

Roll Installation Stage:

The transfer cover moves laterally to the flying shear side;

The roll change trolley pushes the new roll from E6 to E12 (note: lifting tracks are raised, backup rolls and bending force are in roll change position, locking flaps are open);

Locking flaps are closed;

Upper spindle supports are opened;

Upper WR pressure is set to minimum;

The roll change trolley is pushed from E12 to E13;

Lower locking flaps are closed;

Lower spindle supports are opened;

Work roll change tracks are lowered;

Work roll balance is switched to constant pressure;

New roll data is entered;

Required step plate gap for the new roll is calculated and adjusted;

Entry/exit roll wipers and guides are reset;

Entry side guide height is adjusted;

Looper is lowered;

Cooling water is turned on;

The system is switched back to rolling mode.

Common Faults and Solutions:

Fault 1: Cable reel motor trips during trolley movement.

Usually caused by motor overcurrent, triggering thermal relay protection in the MCC cabinet.

Solution: After maintenance resets the thermal relay, reset the fault on the HMI screen.

Fault 2: Transfer cover does not move fully or fails to move.

Causes:

Mechanical obstruction or short movement;

On-site alignment is correct, but HMI does not show “in position”.

Solution:

Check for obstructions; operate valve manually after ensuring safety;

If mechanically aligned, check proximity switch and signal with electrical personnel; replace if faulty.

Fault 3: CVC shifting not in position.

Solution:

Re-execute automatic sequence after confirming WR balance;

If CVC position is incorrect during recovery, set reference position to 0 manually: Nx-RS_WR_REF (G2);

If entry/exit positions differ within 1mm, proceed with closing operation.

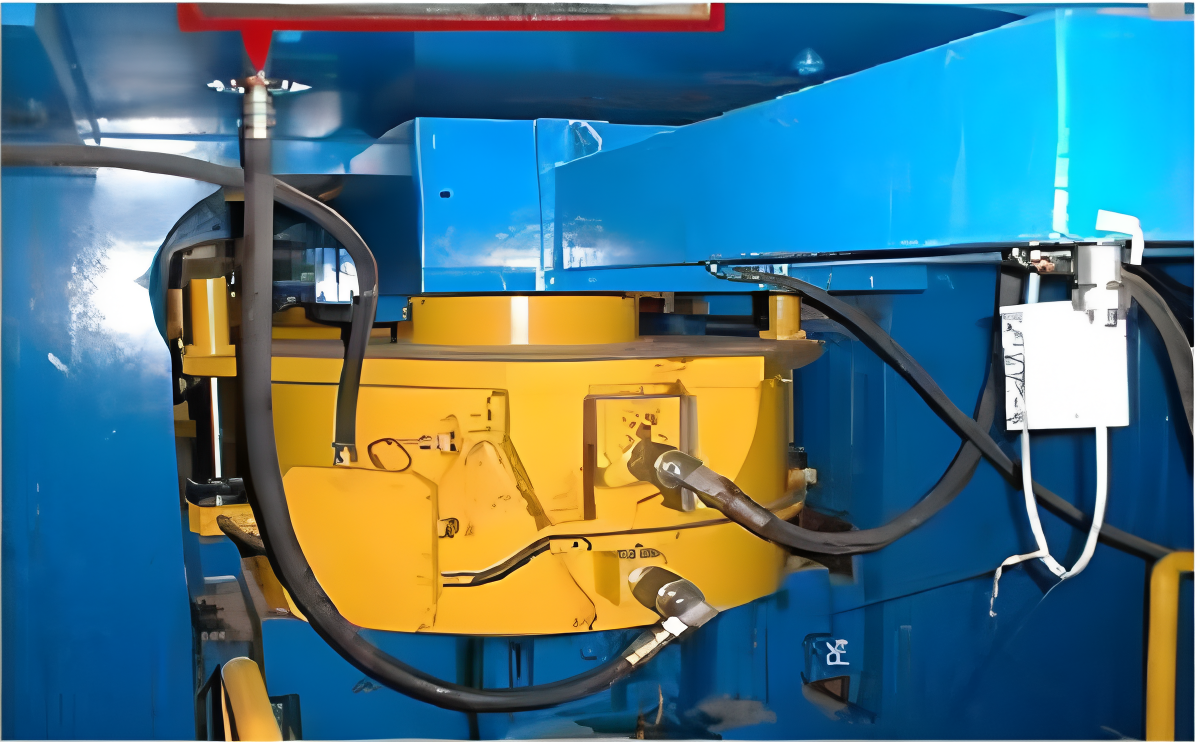

Fault 4: AGC not reaching unload position.

Check:

Actual AGC cylinder position;

Proximity switch signal;

Solenoid valve power status;

Mechanical obstruction.

Fault 5: Spindle positioning signal loss.

Solution: Temporarily bypass in program: Change N3_RC-IN_SOFTWA_I (G3)\LQD552.OR from 16#0000 to 16#0200. Restore after roll change.

Fault 6: Work roll balance not in position.

Check:

Solenoid valve signal output;

Proportional valve output.

Solution: Manually operate valve if needed, then inspect solenoid and electromagnet.

Fault 7: Looper not in position.

Check:

Actual looper position vs. HMI display; adjust encoder or recalibrate;

Ensure exit guides and wipers are clear.

Fault 8: Guides/wipers not in position.

Check:

Proximity switch signals for guides;

Pressure switch values for wipers;

Manually operate valves if necessary.

Fault 9: Lifting track issue.

Check: Proximity switch and solenoid valve signals. Manually operate valve if energized but not acting; replace solenoid valve if faulty.

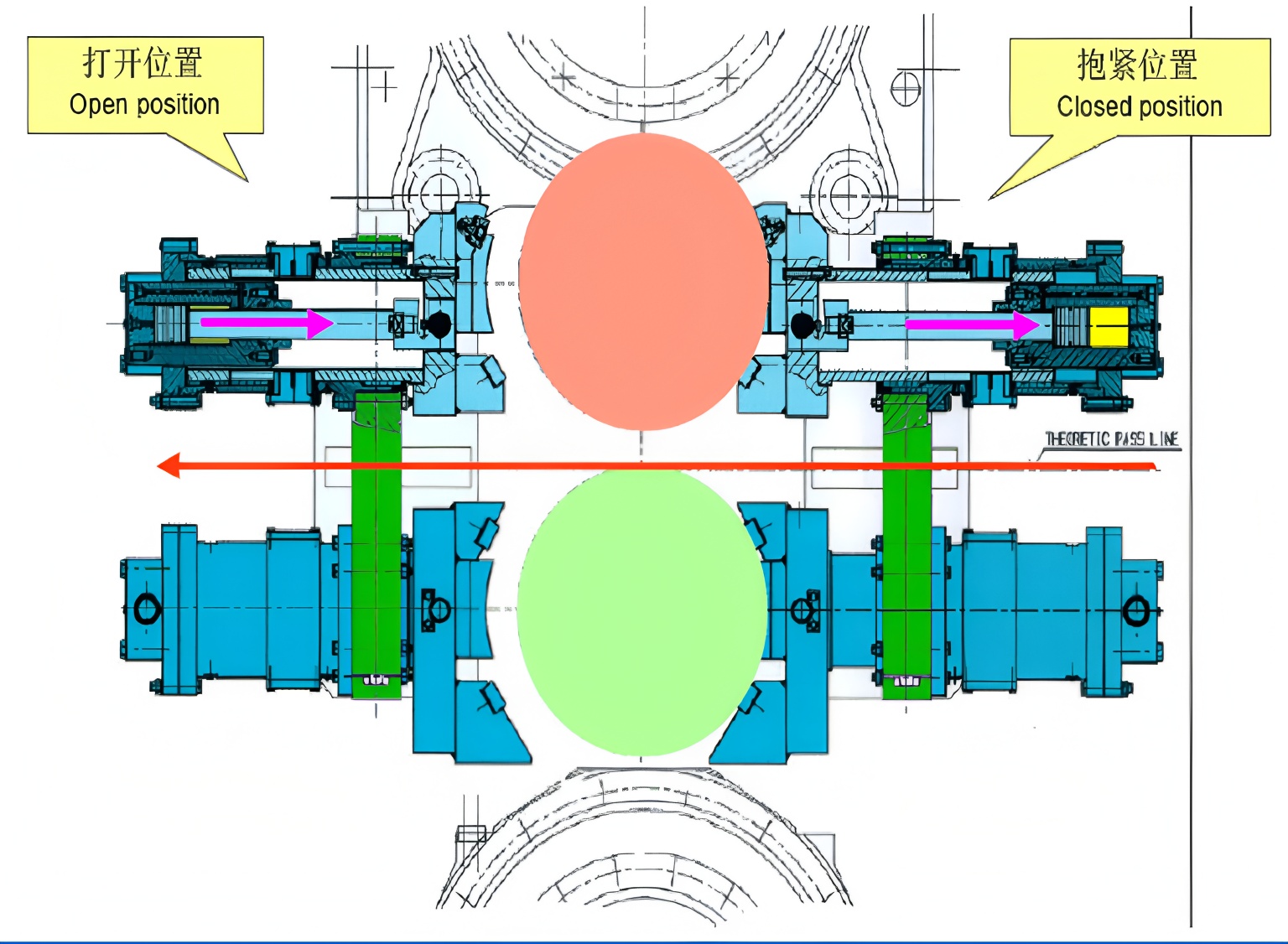

Fault 10: Spindle not clamping during roll change.

Causes:

Proximity switch not activated;

Solenoid valve issue.

Solution: Manually operate valve; replace solenoid valve if stuck.

Fault 11: WR locking flap not opening/closing.

Check:

Mechanical obstruction or trolley position;

Solenoid valve signal and operation;

Hydraulic cylinder connection.

Solution: Manually operate valve; replace solenoid if faulty.

Fault 12: Step plate not adjusting automatically.

Solution:

Verify roll data;

Ensure backup roll balance pressure is 130Bar—switch modes to reset if needed;

Manually adjust step plate after confirmation.