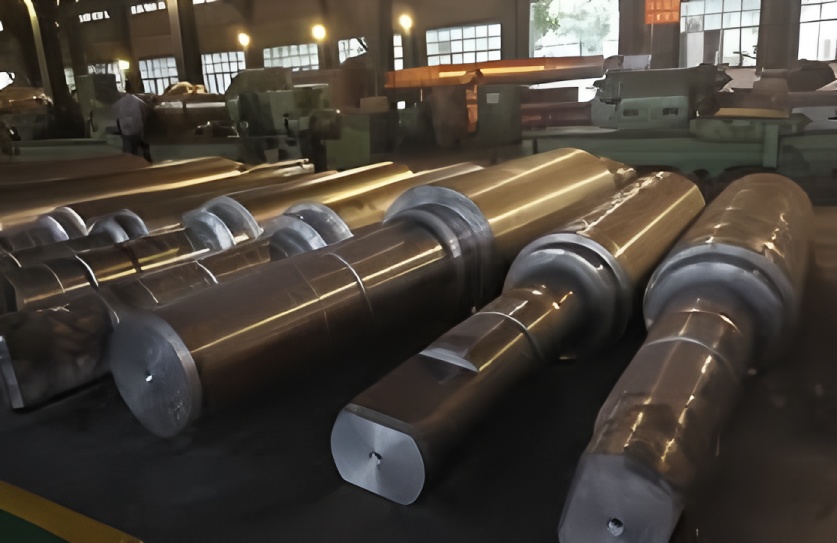

Forged rolls are categorized into forged steel hot rolls and forged steel cold rolls.

chill-rolls

Forged steel hot rolls are primarily used for hot rolling blanking and as roughing rolls in section steel mills.

Forged steel cold rolls are widely employed as work rolls in cold rolling applications.

Due to the high quality requirements of cold-rolled sheets—especially as they are extensively used in light industry, automotive, construction, and railway sectors—producing high-quality cold-rolled sheets necessitates the use of high-performance cold-rolled work rolls. This imposes stringent demands on the properties of cold-rolled work rolls.

The roll body surface must possess high and uniform hardness to ensure dimensional accuracy and excellent surface quality of the cold-rolled strip or plate.

The roll body must have a hardened layer of sufficient depth.

The roll body must exhibit high resistance to accidental damage.

To achieve these properties, the initial microstructure of the roll material must meet strict criteria, including high metallurgical quality and structural uniformity.

High metallurgical quality requires that the steel ingot has dense crystallization, minimal segregation, no permitted white spots, and as low as possible non-metallic inclusion content.

The in-service microstructure of the roll requires carbides to be as fine as possible (0.5–2 microns) and uniformly dispersed. A adequate hardened layer depth is also essential, as increasing its depth can reduce the frequency of re-quenching during use, significantly lowering roll costs.

Rolling Mill Roll Design:

Material of Forged Rolls

To ensure the necessary wear resistance of cold-rolled work rolls, the surface hardness must reach 780–900 HV. Meeting this requirement involves advanced heat treatment quenching and tempering processes. Through these processes, the surface layer of the roll is hardened and tempered, resulting in a martensitic structure at a depth of 25 to 50 mm. HANI uses roll materials made from high-purity steel with C 0.8% and Cr 2–5%. For foil rolling applications, ultra-pure steel produced via electroslag remelting in specialized facilities is employed.Heat Treatment of Forged Rolls

The forging billets are supplied by professional forging plants using open-die forging or precision GFM forging. Prior to heat treatment, forged billets are machined to positive tolerance dimensions and finished to final specifications after heat treatment. The initial heat treatment aims to dissolve carbon into the matrix and spheroidize any remaining compounds.

Conditioning heat treatment is conducted in gas combustion furnaces, each capable of holding 10 rolls. The entire process takes about 10 days from loading to completion. After conditioning, rolls are reheated to approximately 900 °C for austenitization, followed by water spray quenching. Two methods are used:

high speed steel rolls

Quenching of Mill Rolls

(1) Conventional Method: This method uses a new 5-zone vertical gas burner. Rolls are preheated in a preheating furnace utilizing exhaust heat from the austenitizing furnace. The austenitizing furnace employs computer-regulated high-velocity gas burners. After austenitization, the roll surface is quenched with water sprayed at 12–5000 liters/min in a vertical quenching tank, with water flowing through drilled holes along the roll axis. The entire heat treatment process takes about 12 hours.

(2) Induction Heating: HANI utilizes a novel double induction coil furnace that can harden a roll in approximately three hours. The roll surface is gradually heated to the austenitizing temperature via the induction coil. The roll is clamped vertically and slowly descends through the coil. The main induction coil operates at 50 Hz, heating the surface to a depth of about 50 mm to 900 °C.

Due to varying roll types and applications, automated flaw detection time is about 1/4–1/2 shorter than manual inspection. A second induction coil operating at 5 Hz compensates for surface cooling. Directly below the coil, a quenching ring sprays pressurized water onto the roll. The entire operation takes about 3 hours. After quenching, rolls are tempered at 180–200 °C for 24 hours. Approximately 10% of rolls undergo deep cryogenic treatment in liquid nitrogen for 2–4 hours to transform retained austenite into martensite, ensuring isotropic consistency.

After heat treatment, rolls undergo final machining and grinding.

Compared to conventional quenching, induction hardening offers several advantages aside from cost. In fact, fuel cost per roll is lower in the new conventional furnace. The choice of method depends on final performance requirements, such as residual stress and achieved hardened layer depth.