What are the commonly used types of cast iron rolls?

Cast iron rolls are divided into four main categories: chilled cast iron rolls, infinite chilled cast iron rolls, ductile iron rolls, and high chromium cast iron rolls.

Due to differences in composition, inoculation, cooling rate, heat treatment, and other factors, cast iron has developed into a extensive material system. Various types of cast iron rolls possess different structures and properties, making them suitable for use in different kinds of rolling mills.

chill-rolls

Alloy Chilled Cast Iron Rolls

Alloy chilled cast iron rolls (or roll rings) are manufactured by utilizing the inherent supercooling of the molten iron along with the chilling effect of the mold surface, while also adding alloying elements such as Ni, Cr, and Mo. The basic microstructure of the working layer of the roll body contains almost no free graphite, giving it high hardness and excellent wear resistance.

This material can be used to produce large-scale rolls through a static composite casting process, enabling the roll body to achieve high hardness while the roll neck maintains high strength and toughness. This results in good thermal stability and accident resistance.

| Material | C | Si | Mn | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|---|

| CC-1 | 2.9-3.8 | 0.4-1.0 | 0.2-1.0 | 0.2-0.6 | – | 0.2-0.6 | – |

| CC-2 | 2.9-3.8 | 0.4-1.0 | 0.2-1.0 | 0.2-0.6 | 0.5-1.0 | 0.2-0.6 | – |

| CC-3 | 2.9-3.8 | 0.4-1.0 | 0.2-1.0 | 0.2-0.6 | 1.0-3.0 | 0.2-0.6 | – |

| CC-4 | 2.9-3.8 | 0.4-1.0 | 0.2-1.0 | 0.2-0.6 | – | 0.2-0.8 | (0.1-0.3) |

Alloy Infinite Chilled Cast Iron Rolls

In alloy infinite chilled cast iron rolls, graphite is uniformly dispersed throughout the cross-section of the roll body, with its amount and size increasing with depth. The alloy infinite chilled cast iron rolls supplied by HANI are enhanced with the addition of manganese, chromium, nickel, molybdenum, and other alloying elements. The presence of a small amount of fine graphite not only improves the roll’s resistance to peeling, thermal cracking, and wear but also ensures a smaller hardness drop in the working layer of the roll body. Additionally, the fine graphite pores on the surface improve the roll’s biting ability.

chill-rolls

High Nickel-Chromium Infinite Chilled Cast Iron Rolls

High nickel-chromium infinite chilled composite cast iron rolls are high-performance rolls manufactured through centrifugal or full flushing (overflow) methods. By increasing the content of alloying elements such as nickel, chromium, and molybdenum, a microstructure with high microhardness and carbides is achieved. Special heat treatment results in a working layer with a uniform structure, high density, and minimal hardness drop. The presence of a small amount of free graphite provides excellent wear resistance, thermal crack resistance, spalling resistance, and indentation resistance.

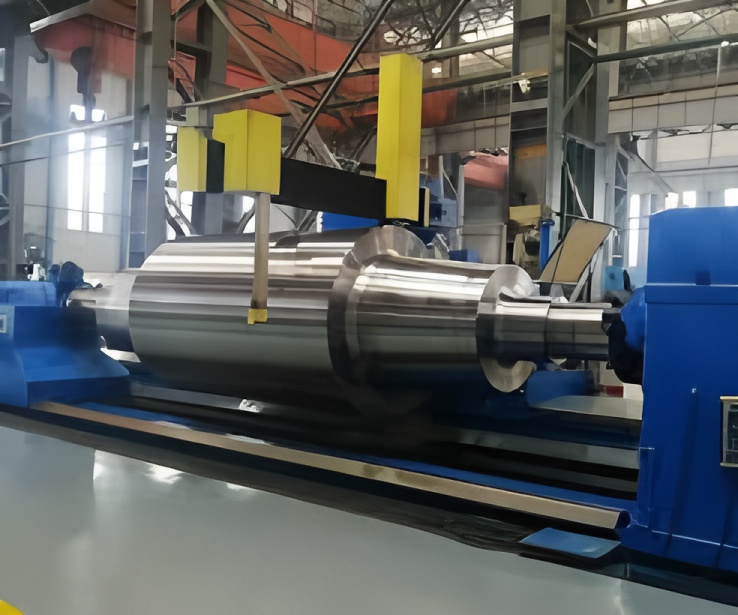

Professional Manufacturer of Chilled Cast Iron Rolls

Established in 2007, HANI is dedicated to producing various types of metallurgical rolls for hot and cold strip mills, bar mills, high-speed wire mills, and other rolling mills.

Covering an area of 100,000 square meters, our facility includes two complete production lines for cast rolls and forged steel rolls, machining workshops, a product R&D center, testing center, training center, office buildings, and other supporting infrastructure. The factory environment is modern and well-maintained.

HANI has been supplying top global steel manufacturers such as ArcelorMittal, TATA Steel, and EZZ Steel for many years. We also have long-term OEM partnerships with Concast and Danieli.