An Overview of Cast Iron Rolls: Types and Characteristics

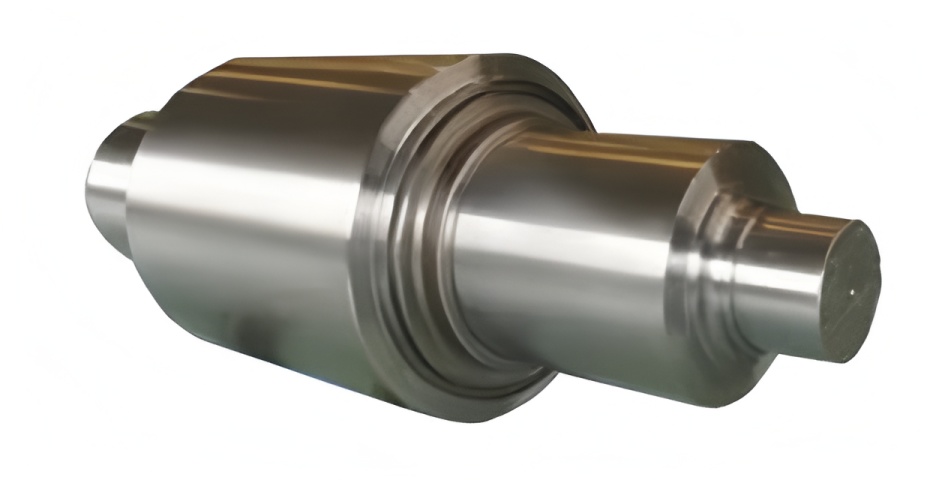

Cast iron rolls are essential components in various rolling mills, offering a range of properties tailored to specific applications. Key types include chilled cast iron rolls, infinitely chilled cast iron rolls, and ductile cast iron rolls, each with distinct characteristics and uses.

🛠️ Types and Characteristics of Cast Iron Rolls

Chilled Cast Iron Rolls

These rolls exhibit excellent wear resistance and provide a smooth surface finish, making them ideal for small-load finishing rolls34.Infinitely Chilled Cast Iron Rolls

Known for their wear resistance, thermal crack resistance, and moderate strength, these rolls are commonly used in hot-rolled strip work rolls, small section mills, and wire rod mills16.Ductile Cast Iron Rolls

With high strength and toughness, these rolls outperform steel rolls in thermal crack resistance and wear resistance. They are widely used in heavy-load hot strip mill work rolls, leveling rolls, and backup rolls16.

🔬 Detailed Types of Alloy Cast Iron Rolls

(1) Alloy Chilled Cast Iron Rolls

These rolls are formed by utilizing the supercooling of molten iron and surface chilling to create a white layer. The working layer has almost no free graphite, featuring a fine pearlite and carbide structure. This provides high hardness and exceptional wear resistance, making them suitable for small bar and wire rod mills and narrow-strip steel finishing mills34.

(2) Alloy Infinitely Chilled Cast Iron Rolls

This material lies between chilled cast iron and gray iron. The working layer contains uniformly distributed graphite, with hardness decreasing gradually from the surface to the core, eliminating a distinct boundary. When alloyed with chromium, nickel, and molybdenum, it becomes a high nickel-chromium infinitely chilled cast iron roll, produced via full flush (overflow) or centrifugal composite casting. The structure contains numerous carbides, offering high wear resistance, while the graphite enhances thermal crack resistance. These rolls are used in finishing stands of wide, medium, and heavy plate mills and strip mills16.

(3) Alloy Ductile Iron Rolls

Graphite is uniformly distributed from the surface to the core, providing high tensile strength, ability to withstand heavy loads, and good wear resistance. The matrix structure consists of carbides, pearlite, or acicular bainite. These rolls are classified into pearlitic ductile iron rolls and bainitic ductile iron rolls based on the matrix structure. They offer excellent thermal shock resistance and wear resistance, and are used in large blooming mills, section steel mills, continuous bar mills, and large seamless tube mills167.

(4) Pearlitic Ductile Iron Rolls

By adding chromium, nickel, and molybdenum to ductile iron and applying special heat treatment, pearlitic ductile iron rolls are produced. They exhibit good strength, high-temperature performance, accident resistance, and minimal hardness drop in the working layer7.

(5) Acicular Bainitic Ductile Iron Rolls

Alloying with nickel, manganese, chromium, and molybdenum results in a needle-like structure (bainite +少量 martensite), offering higher strength, toughness, and wear resistance than pearlitic rolls. These can be produced via static or centrifugal casting, but the centrifugal composite process is preferred for achieving ideal comprehensive properties due to high alloy content and casting stress6.

(6) High Chromium Composite Cast Iron Rolls

Produced by centrifugal composite casting, these rolls use wear-resistant high-chromium white iron (12%–22% Cr) as the outer layer and ductile iron for the core and neck. The matrix contains lath-like M₇C₃ eutectic carbides, chrysanthemum-shaped M₂C eutectic carbides, and granular M₂₃C₆ secondary carbides, providing exceptional wear resistance. They are widely used as work rolls for roughing and finishing in hot strip mills, wide and medium plate mills, and finishing work rolls for small section steel and plate mills25.

🏭 Professional Manufacturer: HANI

HANI, founded in 2007, specializes in manufacturing various metallurgical rolls for hot and cold strip mills, bar mills, high-speed wire mills, and other rolling mills. With a facility covering 100,000 square meters, HANI boasts two complete production lines for cast and forged steel rolls, along with machining workshops, R&D and testing centers, and training facilities. The company supplies top global steel manufacturers like ArcelorMittal, TATA Steel, and EZZ Steel, and has long-term OEM partnerships with Concast and Danieli.

This version maintains the original intent and structure while improving readability and incorporating the requested brand update. Let me know if you need further adjustments!