High-speed wire rod mills ensure precise product cross-sections through accurate pass design, proper tension and looper control, twist-free high-speed continuous rolling, robust mill rigidity, and small-diameter wear-resistant tungsten carbide roll rings. The high rolling speed significantly enhances production efficiency and reduces operating costs compared to conventional mills.

Tungsten carbide roll rings are standard in finishing stands due to their excellent thermal conductivity, minimal high-temperature hardness loss, strong thermal fatigue resistance, high wear resistance, and structural strength.

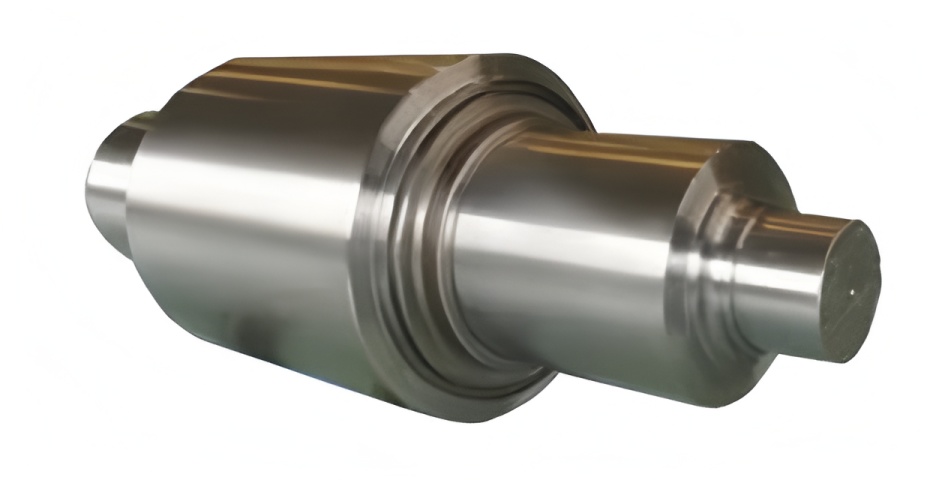

Introduction to Tungsten Carbide Roll Rings

Tungsten carbide roll rings are manufactured via powder metallurgy, distinct from steel or iron rolls. They are produced by mixing refined tungsten carbide particles with a cement-like binder—typically cobalt, sometimes with 0.5%–1.0% nickel or chromium to improve thermal fatigue and corrosion resistance. Before thermal sintering, the powder is finely ground, mixed, and extruded under heat. Production methods include hot pressing, cold pressing, hot isostatic pressing (HIP), and cold isostatic pressing. HIP-produced roll rings offer the best density, highest strength, and superior wear resistance, though at a higher cost due to process complexity.

As rolling speeds and rhythms increase, insufficient attention to roll ring material selection, installation, cleaning, alignment, and maintenance often leads to premature failure in finishing stand inner roll rings. This results in unplanned downtime, reduced output, higher costs, and negative impacts on operational efficiency.

3. Analysis of Causes for Roll Ring Breakage in Finishing Stands

3.1 Improper Roll Ring Material Selection

A high-speed wire rod finishing train typically comprises 8–10 stands, each subject to varying rolling forces, impacts, and wear. As rolling progresses, roll ring speed increases significantly, accelerating wear. Material selection must account for the specific rolling force, impact load, and wear resistance required per stand. Incorrect choices can lead to roll failure, which is often difficult to diagnose.

In early finishing stands, where section sizes and reductions are larger, roll rings should prioritize high strength and thermal fatigue resistance, with wear resistance secondary. Later stands, experiencing lower loads and impacts, should emphasize wear and thermal fatigue resistance.

3.2 Unstable Rolling and Cobbling in Finishing Stands

3.2.1 Incorrect Roll Ring Matching

Morgan high-speed wire rod mills impose strict requirements for inner roll ring and roll matching. The finishing train is collectively driven by a 6000 kW AC variable-frequency main motor with fixed gear ratios between stands, preventing individual speed adjustment. Thus, roll ring outer diameter tolerance for the same pass must be within ±0.05 mm, and no round-pass roll diameter may be smaller than the preceding stand’s. If an oval-pass roll diameter exceeds the previous round-pass roll diameter, strip oscillation between stands can cause cobbling. The heat from cobbling transfers to adjacent roll rings, raising temperatures and concentrating thermal stress. Large differences between cooling water temperature and roll ring temperature can cause breakage.

3.2.2 Incorrect Roll Gap Setting

Operators must set roll gaps strictly according to process specifications to minimize cobbling from misalignment. Proper settings reduce impact forces on roll rings and the risk of thermal stress concentration and breakage.

3.2.3 Poor Entry Stock Dimensions

Oversized stock exiting the pre-finishing mill increases impact force, deformation, and rolling pressure on the first finishing stand. This also raises rolling forces in early stands and causes vibration, increasing the risk of roll ring breakage. Entry section dimensions into the twist-free finishing mill should be controlled within ±1% to ±1.5% of standard values.

3.3 Excessive Impact from Misaligned Guides

Guides in each finishing stand must allow smooth strip passage without impacting roll rings. After replacing guides, inspect entry and exit alignments using a flashlight and mirror. Misalignment causes repeated impacts during rolling, leading to overstress and breakage. Regularly verify guide alignment to reduce impact forces and breakage risk.

3.4 Poor Cooling Water Quality

The roll ring cooling system is critical, especially for tungsten carbide rolls. Inadequate cooling accelerates hot crack formation and propagation in roll grooves, shortening service life. Effective cooling is essential given the high cost of tungsten carbide rolls. Water should be directed as close as possible to the strip exit side, covering the full groove width.

Cooling water pressure should be 0.4–0.6 MPa. Pressure above 0.6 MPa causes water to bounce off grooves, reducing cooling effectiveness; below 0.4 MPa, a vapor layer forms in grooves, impairing heat transfer. Both scenarios can lead to breakage.

Nozzle blockages or insufficient flow cause thermal failure, carbide dispersion, and reduced roll life. Operators should check roll ring surface temperatures during shutdowns to assess cooling effectiveness and prevent breakage from poor cooling.

3.5 Low Installation Temperature of Roll Shaft, Taper Sleeve, and Roll Ring

The finishing mill roll boxes are lubricated by a dedicated system that also heats components to ensure continuous operation at suitable temperatures. Oil leaves the tank at ~40°C, raising roll shaft temperatures to ~25°C after circulation. This minimizes temperature differences between roll shafts, taper sleeves, and roll rings during installation, preventing excessive stress and breakage.

In northern regions, large day-night temperature differences cause roll shaft temperatures to drop sharply after lubrication system shutdown. Upon resuming operation, roll shaft temperatures rise, causing thermal expansion and increased interference fits, which can lead to roll ring脱落 or breakage. Storage areas for taper sleeves and roll rings should be heated to ensure pre-installation temperatures. After lubrication system stoppage, pouring boiling water on roll shafts can raise their temperature before installation to avoid breakage from large temperature differences.

3.6 Issues with Roll Ring Installation Carts

Installation carts are critical for proper roll ring mounting. If cart working pressure is insufficient, interference fits between roll rings, taper sleeves, and roll shafts may be inadequate, causing taper sleeves to loosen and roll rings to fail. Excessively high pressure (e.g., above 7100 PSI) can also cause breakage. Regularly maintain and inspect installation carts.

3.7 Severe Wear of Taper Sleeves and Roll Shafts

Inadequate cleaning of oxide scale, rust, oil, or particles from taper sleeves and roll shafts accelerates wear. Oil residue reduces friction, causing roll rings to loosen or fail. Oxide scale and particles between taper sleeves and roll shafts cause wear over time. Morgan requires ≥85% contact between taper sleeves and roll shafts; otherwise, poor contact can cause taper sleeve withdrawal and roll ring failure. Regularly inspect contact surfaces using blue powder to ensure ≥85% contact.

Worn taper sleeves should be reconditioned to ensure good contact. The outer surface of taper sleeves and inner bore of roll rings should have a close fit—tight to 0.005 mm or loose to 0.035 mm. This allows hydraulic thrust to build pressure between them rather than expanding the taper sleeve to eliminate radial clearance.

Additional factors such as roll ring cleaning, installation quality, handling, and manufacturing density also contribute to breakage and require attention.

Our plant has achieved significant results by analyzing each roll ring breakage and implementing effective measures, reducing economic losses and generating considerable benefits.

4. Conclusion

4.1 Finishing stand roll breakage reduced from 3–4/month to 1–2/half-year. At an average cost of ¥7,000 per roll ring, this avoids ~¥300,000 in direct annual losses.

4.2 Each breakage requires roll ring replacement. If no matching roll ring is available, all finishing stand roll rings must be replaced. Assuming 10 minutes per pair replacement, unplanned downtime from breakage is 480 minutes annually. At 2 minutes per wire rod, this reduces output by 240 rods/year. At ¥4,000/rod, annual lost output value is ¥960,000. Total direct and indirect losses from breakage exceed ¥1.3 million annually.

4.3 Strengthening process and technical management to control finishing stand roll breakage is essential for high output, reduced costs, increased productivity, and minimized unplanned downtime. This enables effective utilization of high-speed mill capacity, stable output growth, and enhanced competitiveness, delivering higher economic benefits.