High-speed steel rolls demonstrate exceptional wear resistance, offering 3–6 times longer service life than high-chromium iron rolls in hot tandem mill finishing stands. However, challenges such as significant thermal expansion, high friction coefficients, and oxide film detachment have limited their optimal utilization. Addressing these issues is crucial for improving on-site performance.

Performance Characteristics of High-Speed Steel Rolls

Wear Resistance

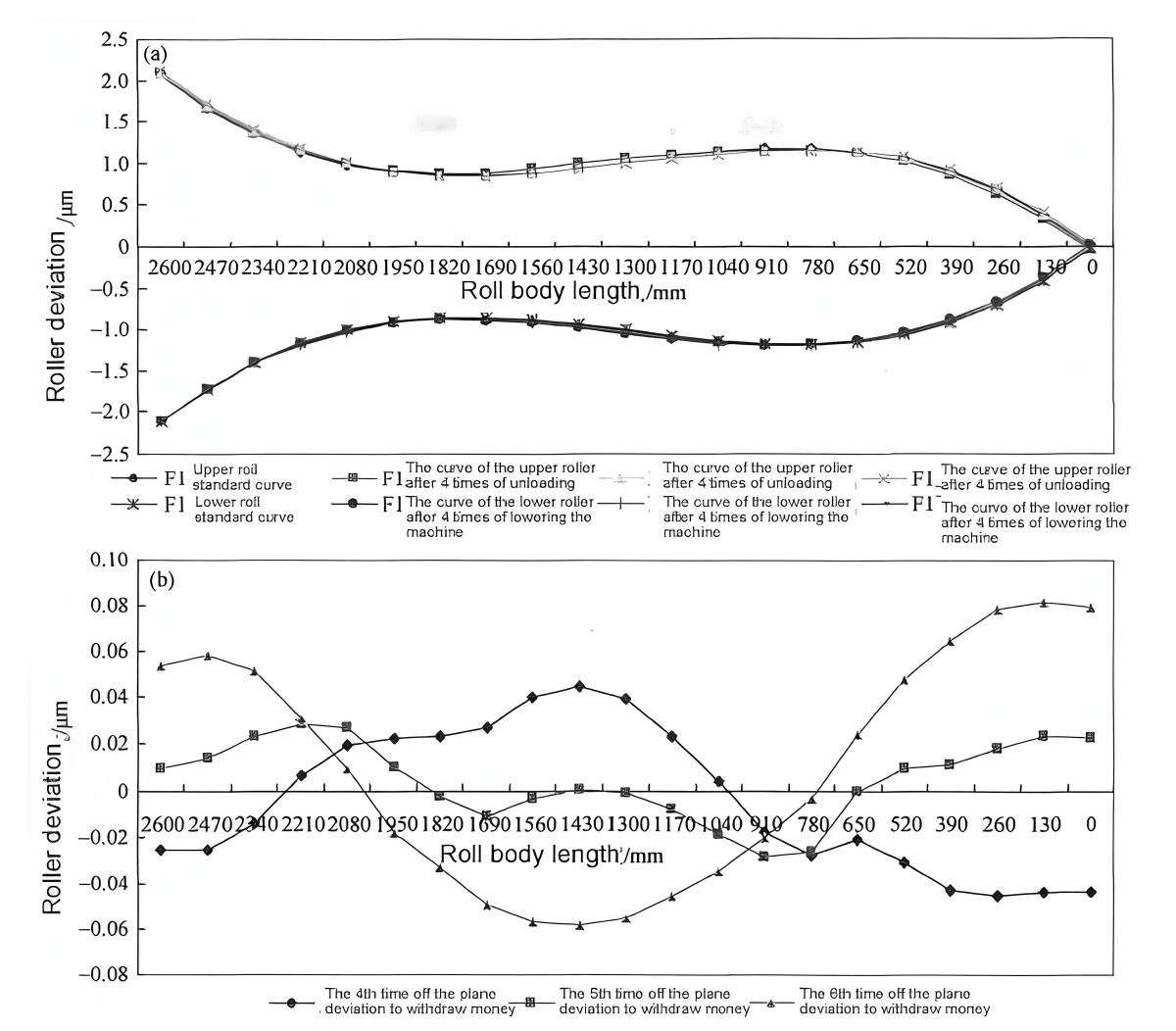

High-speed steel rolls are typically used multiple times between regrinding cycles and are air-cooled after removal. Figure 1 illustrates the measured roll profile and deviation curves for F1 stand rolls in a 2300 hot-rolling line after six consecutive uses. The rolls maintained excellent wear resistance, though surface roughness increased after the fifth use.

Surface Oxide Film

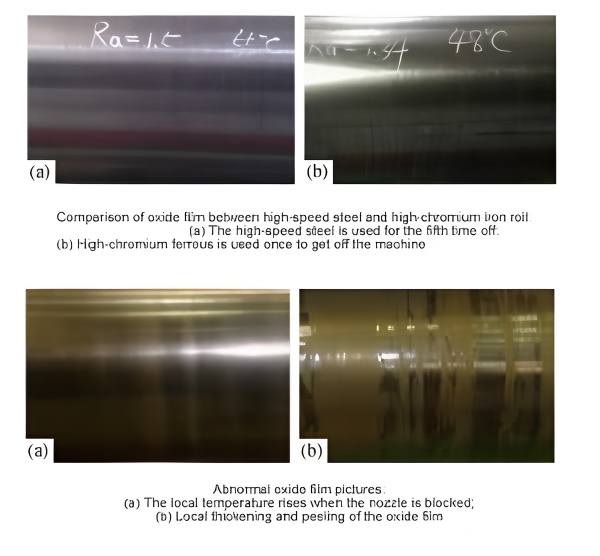

During contact with hot strip, a uniformly distributed silver-gray or light blue oxide film forms on high-speed steel roll surfaces. Figure 2 compares the oxide film morphology of F1 stand high-speed steel rolls after five uses versus high-chromium iron rolls after one use. The maximum roughness (Ra) was 1.5 μm for high-speed steel rolls and 1.34 μm for high-chromium iron rolls, indicating comparable roughness retention despite extended use.

Oxide film formation and detachment represent a dynamic balance between oxidation and friction. Initially, a surface oxide film forms rapidly at high temperatures. During use, the film thins while ion diffusion through the film enables continued oxidation of the underlying material, maintaining a relatively stable thickness. Hot cracks in the oxide film exhibit heredity, with quantity, depth, and width increasing over successive rolling cycles. Axial-parallel cracks are particularly evident, and surface roughness progressively increases with use.

Thermal Expansion

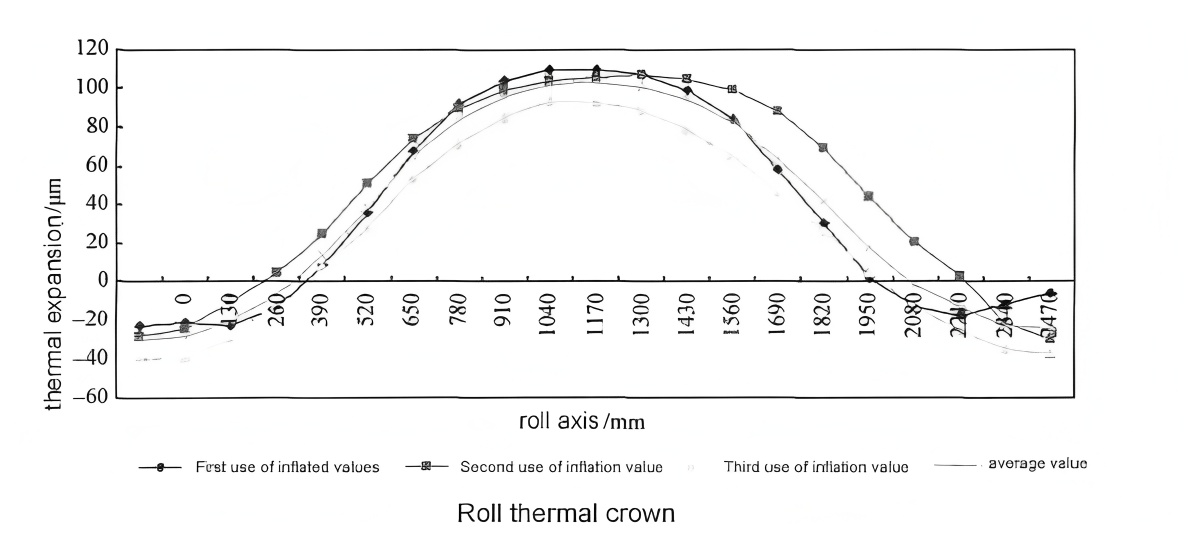

Continuous contact with hot strip causes thermal expansion in high-speed steel rolls. Figure 4 shows the thermal crown of F1 stand rolls measured 30 minutes after the first to third uses in a 2300 hot-rolling line. With a roll surface temperature of 55°C, the maximum thermal crown reached 120 μm. Three main factors affect the loaded roll gap: initial roll profile, thermal expansion, and wear. Since the loaded gap determines strip profile and flatness, controlling thermal crown and wear is essential.

Strategies for Use and Maintenance of High-Speed Steel Rolls

Roll Cooling

Thermal expansion correlates directly with roll surface temperature. Uneven temperature distribution can lead to irregular thermal expansion, abnormal oxide film detachment, and compromised product surface quality. To ensure consistent performance, precise control of roll surface temperature is necessary. In one case, optimizing cooling water distribution by increasing flow to the roll body center promoted uniform temperature and oxide film integrity. Although small wear makes thermal expansion more noticeable, minimizing it remains critical, requiring effective cooling of the work roll center.

Rolling Lubrication

Hot rolling lubrication involves spraying an oil-water mixture onto the roll surface before strip entry. The lubricant combusts, leaving residues and forming a high-temperature, high-pressure air cushion in the deformation zone. This isolates the roll from the strip, reducing friction. Lubrication also forms a protective film, lowering rolling force, temperature, and wear, improving roll surface condition, and minimizing scale embedment. To maintain effectiveness, regularly clean lubrication pipelines, verify oil spray volume during maintenance, and calibrate flowmeters. Lubricated rolling typically reduces rolling force by approximately 20%.

Usage and Maintenance

Determining Usage Cycles Between Grinding: Base the number of uses on oxide film condition, roughness, and strip grade. Upstream stands typically allow more uses (3–6 cycles) than downstream stands if oxide films and roughness remain acceptable.

Temperature Monitoring of Lower Rolls: Monitor roll surface temperature distribution to guide cooling nozzle maintenance and prevent oxide film peeling that could affect strip surface quality.

Inspection: After unloading, air-cool rolls to eliminate thermal expansion effects. If abnormal rolling causes severe thermal cracking, replace rolls immediately. Use automated or portable ultrasonic testing to detect cracks after cooling, and remove any identified defects before reuse.

Conclusion

(1) Thermal crown and wear significantly impact hot rolling. While high-speed steel rolls address wear, their thermal crown requires careful management.

(2) A uniform, stable oxide film enables multiple uses between grinding, though roughness gradually deteriorates with repeated use.

(3) Combining optimized cooling, roll profiling, and lubrication maximizes high-speed steel roll performance.

(4) Strict usage protocols and surface crack inspection are essential to prevent failures.

Professional High-Speed Steel Roll Manufacturer

Established in 2007, HANI GROUP specializes in producing metallurgical rolls for hot and cold strip mills, section steel mills, bar mills, and high-speed wire rod mills.

The company operates from a 100,000-square-meter facility equipped with two complete cast and forged roll production lines, machining workshops, R&D centers, testing laboratories, training centers, and office buildings in a well-maintained environment.

HANI supplies top global steel producers such as ArcelorMittal, TATA Steel, and EZZ Steel, and provides long-term OEM services for industry leaders including Concast and Danieli.