Hot-rolled section steel offers advantages including large-scale production, high efficiency, low energy consumption, and cost-effectiveness, making it the dominant manufacturing approach. This article outlines the following rolling methods:

Conventional Rolling Method

This method is performed on standard two-high or three-high mills, where the pass is formed by grooves on two rolls. It produces simple and special sections, as well as longitudinally rolled periodic sections. Due to its simplicity, this method is still widely used in section mills.Multi-Roll Rolling Method

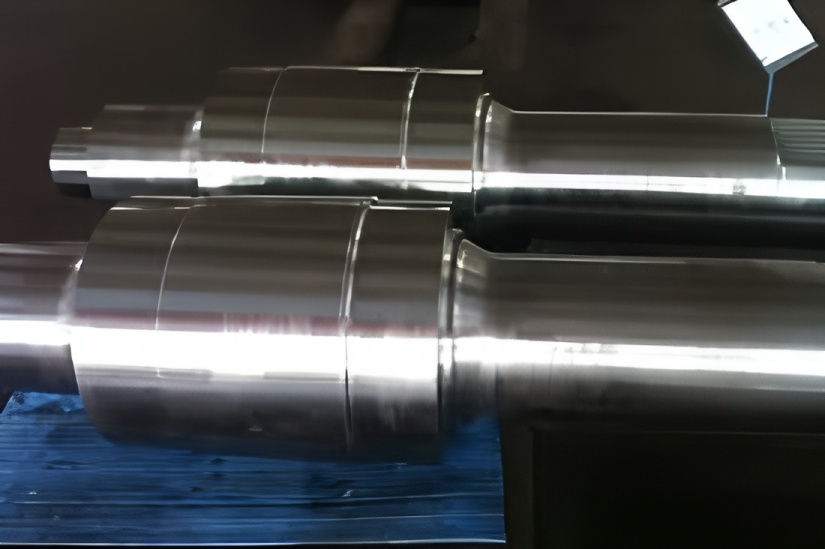

In this approach, the pass is formed by three or more roll grooves, which reduces drawbacks associated with closed grooves and minimizes roll diameter differences. It enables the production of parallel-flanged economical sections with increased flange height, along with special sections unattainable through conventional rolling. Benefits include high precision, reduced roll wear, lower energy consumption, and less rolling scrap. H-beams are a typical product of this method.Hot Bending Method

The process begins by rolling the billet into a flat strip resembling the final section shape, followed by hot bending in subsequent passes. It can be implemented on conventional mills or in-line horizontal-vertical rolling setups, producing bent sections that standard methods cannot achieve.Hot Rolling – Longitudinal Slitting Method

This technique involves designing asymmetrical sections—which are difficult to roll—as symmetrical ones, or small sections as larger parallel sections to enhance mill capacity. After rolling, the product is slit longitudinally using a disc slitter either on the mill or after cooling.Hot Rolling – Cold Drawing (Rolling) Method

Suitable for high-precision profiles, this method yields products with superior mechanical properties and surface quality compared to conventional hot-rolled sections. Tolerances can reach Grades 3–4, and surface finish Grades 5–7, allowing direct use in mechanical components. It improves efficiency and reduces metal consumption, making it ideal for retrofitting older mills for small-batch, multi-variety production. The process involves hot-rolling to near-final shape with cold-working allowance, followed by pickling, alkali washing, rinsing, lubrication, and cold drawing (or rolling) into the final product.Hot and Cold Bend Forming Method

Using hot- or cold-rolled strip as the raw material, this method feeds the strip through rotating rolls with specially shaped grooves to induce transverse bending, forming the desired cross-sectional profile.