Title: Analysis of Rolling Table Failures in Steel Rolling Technology

Description: This article primarily discusses the causes and analysis of rolling table failures in steel production.

Keyword: rolling table, bearing seat, steel billet

The conveying roller table is the most numerous equipment in the rolling production line and also the most prone to failures. Due to the continuous nature of rolling production, any roller table failure that causes stoppage will interrupt production. The bevel gear drive roller table supported by traditional bearing seats is a common structure in medium and large steel rolling production lines, but the production losses caused by its failures are substantial. For a medium section production line with an annual output of 300,000 tons using bevel gear drive roller tables, the average daily downtime caused by roller table failures exceeds two hours. For such a production line, one hour of downtime incurs costs of approximately 5,000 yuan in coal consumption and labor, leading to annual economic losses of over three million yuan. Therefore, reducing the failure rate of roller tables and minimizing emergency repair time are key to improving the profitability of steel rolling enterprises.

Analysis of Rolling Table Failure Causes

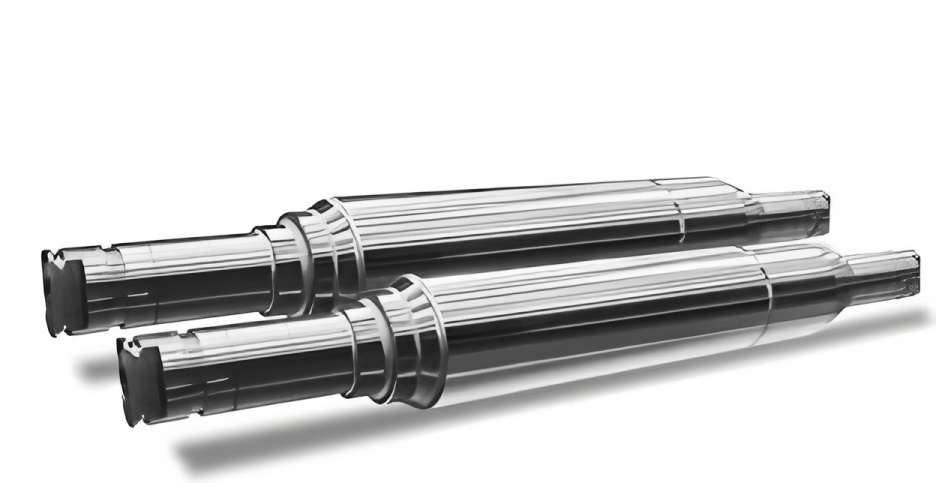

The working characteristics of steel rolling tables include high temperatures of conveyed billets and relatively heavy conveying loads. Traditional bearing seat-supported roller tables have two structures: chain drive and bevel gear drive. This analysis focuses on bevel gear drive roller tables.

1. Analysis of Roller Bearing Damage Causes

① Bearing Seat Alters Bearing Design Oil Clearance

A key characteristic of steel rolling tables is the high temperature of transported billets. When hot billets are conveyed, heat transfers directly to the bearing rings through the roller table shaft, causing the bearing to expand axially and radially. In traditional bearing seats, axial expansion is possible as the bearing chamber width often exceeds the bearing width by over 10%, preventing “burning damage.” However, radially, the fixed structure of upper and lower bolts in the bearing seat restricts chamber diameter changes. As the bearing ring expands with rising temperature, the outer ring is constrained by the seat, reducing the designed oil clearance between rings. This leads to bearing overheating due to insufficient clearance, rapidly increasing temperature until “locking.”

Some companies design water-cooled roller bearing seats to lower temperatures and extend bearing life. This measure has pros and cons: it cools the outer ring, preventing lubricating oil from drying out and reducing oil starvation, but it also reduces the oil clearance between outer rings, accelerating bearing heating and damage.

② Bearing Seat Causes Non-Concentric Bearing Operation

High temperature, heavy loads, and significant impact define the unchanging working environment of rolling tables. Even initially level roller tables deform during production. Two bearing seats fixed on a roller table may become non-concentric, causing bearings on the same roller table to operate misaligned. The “separation force” from non-concentric operation acts on the bearings, significantly reducing service life.

③ Bearing Seat Hinders Inspection and Lubrication

Steel rolling production requires frequent bearing inspection and lubrication. However, the bolted upper cover of traditional bearing seats must be removed for these tasks. The continuous nature of rolling production prevents frequent shutdowns, often leading to oil starvation and accelerated bearing damage.

④ Poor Bearing Seat Sealing, Water and Dust Severely Affect Bearing Life

Rolling production generates substantial dust, often hard metal compounds. Ingress of such dust into bearings causes severe damage and shortens life. Additionally, process or equipment requirements necessitate water spraying (splash water) on roller tables. Water entering the bearing chamber with dust exacerbates damage. Traditional bearing seats have flat contact seals at upper and lower openings, with most input/output shaft holes unsealed or仅有普通毛毡密封. Often, seals are ineffective, forcing bearings to operate in oil-water-dust mixtures, severely impacting lifespan.

2. Failure Analysis of Bevel Gear Drive Roller Tables

Bevel gear drive roller tables offer smooth transmission and low noise but suffer from high failure rates and long replacement times. Failures primarily involve bearing damage and bevel gear wear. Limited installation space necessitates using light, narrow series bearings with inherently lower life. Combined with axial forces from bevel gears, high bearing failure rates are inevitable. Additionally, bevel gears wear quickly, and slight axial bearing clearance alters meshing conditions, soon leading to “bald tips” and failure. Thus, bevel gear drive roller table failures often exceed twice those of other drive types.

3. Comparison of Emergency Repair Times for Rolling Table Failures

In rolling production, failures of roller table bearings or bevel gears require immediate repair to minimize downtime. For chain drive roller tables, besides preparation and hoisting, emergency repair mainly involves disassembling/reassembling the bearing seat upper cover, typically taking about 30 minutes. For bevel gear drive roller tables, besides preparation and hoisting, emergency repair requires disassembling/reassembling the bearing housing cover, bevel gear box, bevel gear, and bearings, usually taking over two hours.