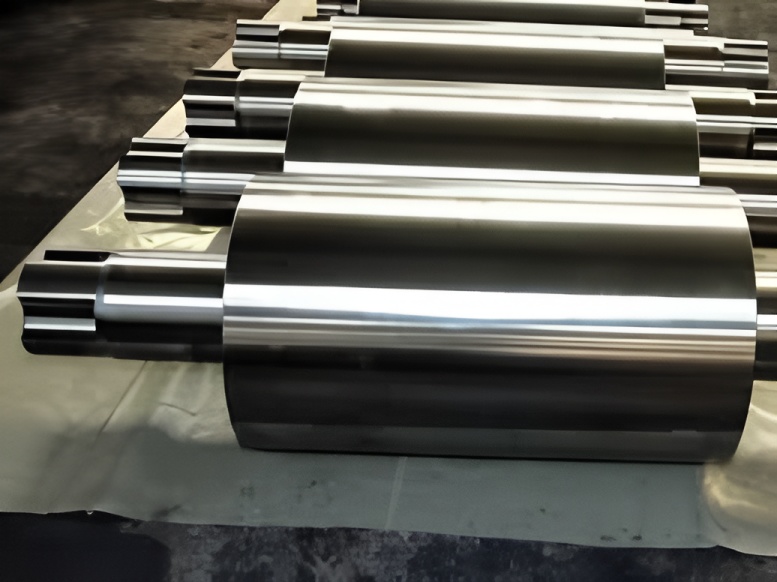

Related products: rolling mill rolls, tungsten carbide roller rolls

Morphology and Causes of Inner Folding in Hot-Rolled Seamless Steel Pipes

1.1 Morphology of Inner Folds

The morphology of inner folds in hot-rolled seamless steel pipes varies significantly. Common forms include fine flakes, large flakes, straight lines, and fish-scale patterns.

1.2 Causes of Inner Folding

During piercing operations, tensile stress can cause central metal fracture in continuous cast pipe blanks, forming cavities. Due to the unpredictable nature of cavity formation, the inner metal surface becomes rough and oxidizes through contact with cooling water and air. These oxidized surfaces then form folds during subsequent rolling processes, adhering to the pipe’s interior. Therefore, preventing cavity formation is crucial for avoiding inner folding defects and represents the core focus of this research.

2. Continuous Cast Pipe Blank Quality and Inner Folding Defects

In current continuous cast pipe blank production, obtaining capillary pipes free from inner folds and surface cracks is essential for producing finished pipes meeting relevant standards. This requirement makes smelting technology level critical to overall production quality. Based on current continuous cast billet smelting research results, quality control should be implemented according to Table 1 specifications to ensure smelting process quality meets expectations.

3. Piercing Process and Inner Folding Defects

3.1 Piercing Temperature and Inner Folding

In seamless steel pipe production, piercing temperature significantly impacts inner folding formation. During continuous cast billet piercing and heating, excessive temperature or prolonged heating time rapidly increases piercing temperature, leading to inner folding defects. Under these conditions, fish-scale inner folds appear inside the continuous cast billet. Conversely, insufficient temperature affects heating duration and compromises metal plasticity. This demonstrates the importance of understanding the relationship between piercing temperature and inner folding defects.

3.2 Piercing Roll Rotation Speed and Inner Folding

When designing piercing roll rotation speeds, multiple factors must be considered including material properties of continuous cast pipe blanks and roll diameter dimensions. Different specification pipe blanks require significantly different speeds. Current practices mainly involve speeds either higher or lower than standard values. Under varying production conditions, these speed types show明显 differences in inner folding ratios. Research indicates higher speeds are more likely to cause inner folding because increased roll speed enhances pipe slippage, reduces axial efficiency, and consequently increases inner folding risk. Based on these findings, timely adjustment of piercing direction and using maximum bite angle for production can effectively prevent inner folding. Increasing the bite angle improves continuous cast pipe blank slippage, reducing rotations during biting.

3.3 Piercing Plug and Inner Folding Defects

Severely worn plugs with uneven surfaces can scratch inner walls during piercing, creating spiral inner folds in pipes. Plug shape also affects pipe quality: (1) Tapered plugs increase reduction from tip to hole, compromising waste pipe quality; (2) Spherical plugs facilitate predetermined waste pipe feeding direction with corresponding reduction amount decrease, ensuring waste pipe quality. Currently, the optimal plug shape maintains consistent pressure along the deformation zone length. Under plug screw action, continuous cast pipe biting performance is guaranteed, achieving expected inner folding control effectiveness.

4. Preventive Measures Research

To effectively prevent inner folding defects, focus on these key aspects:

(1) Strictly control continuous cast pipe blank properties according to production requirements, expanding equiaxed crystal ratio or correspondingly shortening columnar crystal length to reduce folding probability.

(2) Develop strict continuous cast billet heating systems based on production requirements. Determine appropriate heating temperatures according to billet diameter, length, and material specifications, implementing waiting-rolling stop cooling systems. Temperature control formula: Continuous cast billet heating temperature = Penetration temperature – Piercing temperature + Discharge temperature.

(3) Utilize high-quality piercing and rolling tools. These play vital roles in preventing inner folding defects. Actively replace hot centering punches and promptly correct centering holes after routine inspections to avoid production quality impacts. For new piercing rolls, use larger head extension and bite angle parameters with quality control following low roll speed standards.

Conclusion

This research examines inner folding defects in hot-rolled seamless steel pipes and analyzes control methods. Results indicate that effective prevention requires comprehensive approaches including material quality control, heating temperature management, and high-quality equipment utilization. Proper implementation of these measures ensures effective inner folding prevention and maintains hot-rolled seamless steel pipe performance quality.