Related Product: https://hanirolls.com/

Pitting Defect

Irregularly distributed individual pits with overall banded distribution. Under microscopy, pockmarks consist of numerous tiny pits containing fine particles. The impurity elements in these pits match mold powder composition, indicating these inclusions primarily originate from mold powder.Center Cracks in Cold-Rolled Sheet

Numerous flaky fragments appear at crack centers. Larger flakes contain multiple small particles with brittle fractures. The fine particles share similar composition with mold powder, confirming these inclusions mainly derive from mold powder.Edge Cracks in Cold-Rolled Sheet

Zigzag-shaped cracks containing various-sized particles. No significant gap exists between particles and matrix. Some particles align parallel to the crack direction. These particles also originate from mold powder.Ribbon Peeling

A distinct thin layer near the slab surface appears separated or semi-separated from the substrate. Powdered substances accumulate beneath the surface layer. Energy spectrum analysis confirms these substances mainly come from modified mold powder.Discontinuous Point-Line Defects

Common in sheets thinner than 1mm. Linear defects typically appear in clusters, with silicate composite inclusions remaining at defect bases. These result from inclusions enriched in the slab shell, subcutaneous, and central regions of CSP cast slabs, becoming visible as thickness decreases during hot rolling.Black/Gray Line (Band) Defects

After pickling, macroscopic appearance shows strips, bands, blocks, or multiple spots with clearly defined contours.

Primary Causes:

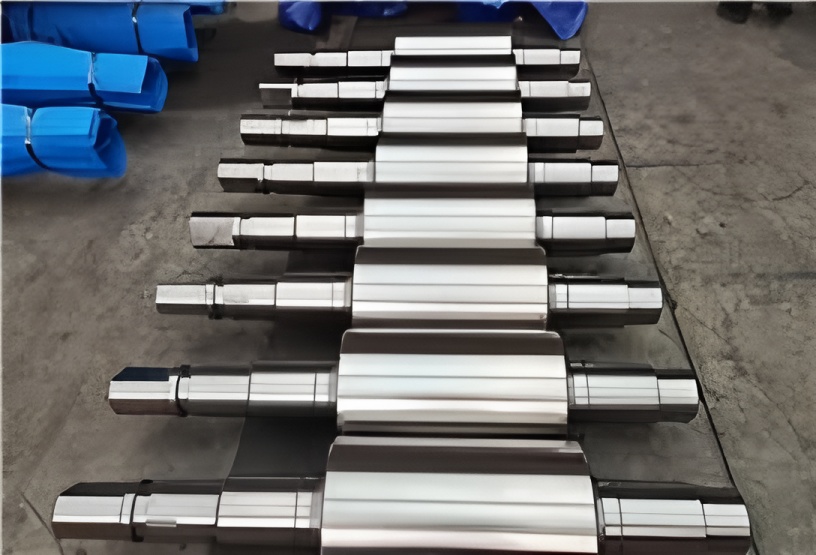

Poor roll quality: Oxide film peeling, aging roughness, spalling, foreign material adhesion

Inadequate descaling: Nozzle blockage, low nozzle pressure

Process factors: Non-standard inter-stand cooling water control

Conveyor roller table scratches (before continuous casting to F7): Furnace roller nodules, foreign material adhesion, idle rollers

These factors cause scale embedding, subsequently forming black/gray line (band) defects on cold-rolled sheets.