Proper Selection & Design Considerations

Accurate Load Calculation

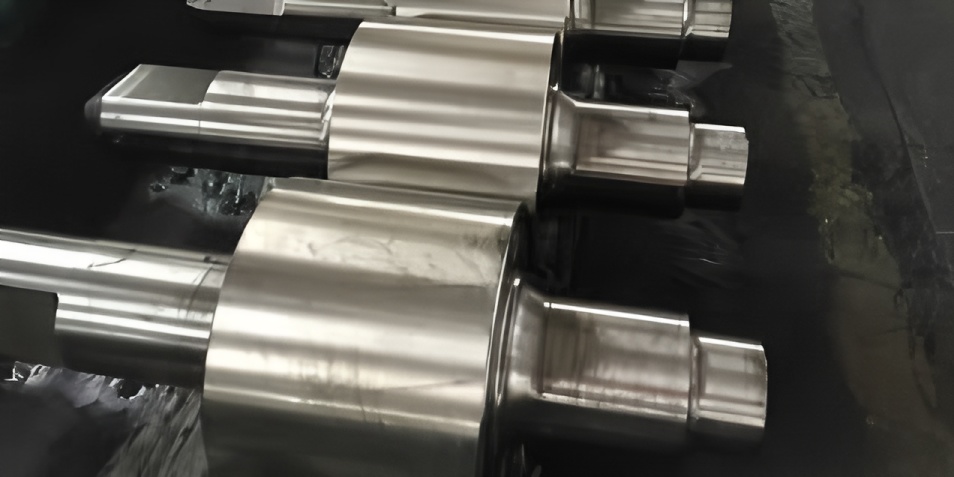

Determine maximum operational loads by analyzing material properties (including alloy steel thickness), width, and production speed.

Select rolls with superior stress resistance for processing high-strength materials.

Specification Alignment

Match roll diameter, length, and material to specific load requirements.

Utilize larger diameters to enhance load capacity and extended lengths for improved weight distribution across wide materials.

Safety Margin Implementation

Incorporate a 1.2-1.5x safety factor to accommodate unexpected variables like material inconsistencies or sudden pressure spikes.

Standardized Operational Protocols

Parameter Optimization

Maintain preset tension, force, and speed parameters to prevent deviations from design specifications.

Material Quality Control

Screen incoming materials for consistent thickness and surface defects to prevent uneven stress distribution.

Gradual Operational Transitions

Implement phased startup and shutdown procedures to minimize risks of mechanical shock.

Advanced Monitoring & Protection Systems

Real-Time Performance Tracking

Deploy sensors to monitor vibration, torque, and pressure metrics for proactive operational adjustments.

Automatic Safety Interventions

Install overload protection mechanisms that trigger emergency stops when predefined thresholds are exceeded.

Predictive Analytics Integration

Utilize historical performance data to identify wear patterns and optimize maintenance scheduling.

Comprehensive Maintenance Strategies

Scheduled Inspections

Conduct bi-monthly checks for surface wear, bearing alignment, and overall structural integrity.

Contamination Prevention

Implement daily cleaning routines to remove debris that increases operational resistance.

Lubrication Management

Apply high-temperature resistant greases at recommended intervals to reduce friction-related stress.

High-capacity industrial roll systems

Overload prevention in metal rolling

Roll surface wear monitoring techniques

Precision roll alignment protocols

Industrial bearing lubrication best practices