Process Characteristics of Hot Rolling, Cold Rolling and ESP Steel Coils

Reasonable Setting and Control of Rolling Parameters

Accurate Rolling Force Calculation

Calculate rolling forces using professional formulas before operation

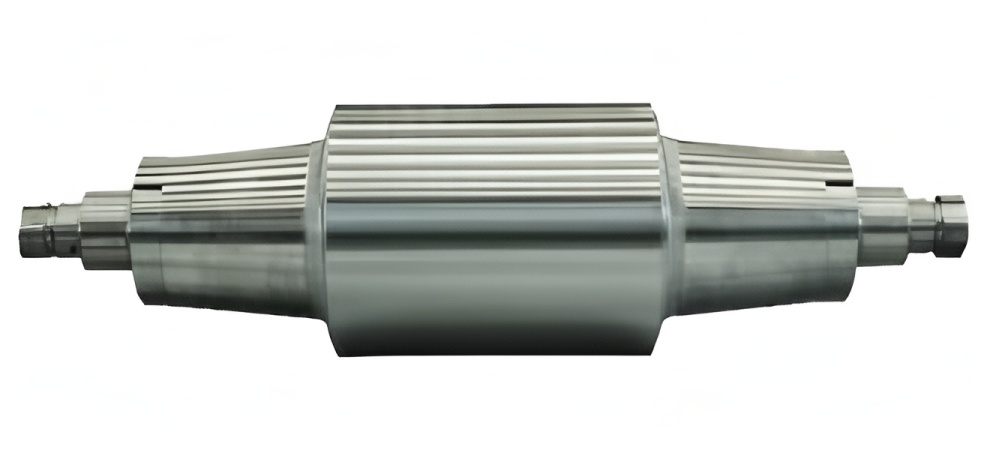

Consider strip material (steel, aluminum, copper alloys), thickness, width, and roller specifications

Set calculated values precisely in mill control systems

Ensure forces remain within roller rated capacity

Use experimental rolling or computer simulation for new materials

Example: Conduct trial rolling for composite strips to determine optimal force settings

Optimized Speed and Tension Control

Select appropriate rolling speeds based on roller capacity and material characteristics

Reduce speeds for harder, thicker materials to minimize friction and heat

Follow manufacturer recommendations while incorporating quality feedback

Example: Start with lower speeds for hard alloy steels, gradually increasing as material thins

Determine tension ranges through theoretical and practical methods

Monitor real-time tension variations using sensors

Maintain stable tension through automated control systems

Example: Calculate optimal tension for cold-rolled aluminum strips based on dimensions

Enhanced Equipment Monitoring and Troubleshooting

Advanced Monitoring Systems

Install high-precision sensors for real-time performance tracking

Utilize pressure, displacement, vibration, and temperature sensors

Implement automatic alarms when parameters approach critical levels

Example: Pressure sensors trigger alerts when forces near rated limits

Analyze data trends using mathematical models

Predict overload risks through vibration and temperature patterns

Example: Identify abnormal conditions through sudden vibration increases

Prompt Incident Response

Activate automatic correction systems for strip deviation

Manual intervention when automated systems fail

Immediate shutdown for foreign object detection

Implement metal detectors and emergency stop protocols

Example: Clear foreign objects and inspect rollers before restarting

Scientific Production Planning

Optimized Rolling Sequences

Schedule production based on roller capacity and material difficulty

Process thinner, softer materials before thicker, harder ones

Example: Roll thin aluminum plates before thick steel plates

Use lighter loads for equipment warm-up and debugging

Balanced Equipment Utilization

Distribute production tasks across multiple roller sets

Match material specifications to appropriate mill units

Consider roller diameter, material, and rated capacity in task allocation

Example: Allocate thick and thin strip rolling to suitable mills in large workshops