Abstract: Macro-etching, metallographic examination, scanning electron microscopy, and energy spectrum analysis were employed to investigate the fracture surface of a failed backup roll from a 3500 mm Steckel mill. Results indicate that significant residual stress combined with the accumulation and distribution of various inclusions and carbides were the primary causes of the ultra-large backup roll fracture.

Keywords: backup rolls; fracture; inclusions; carbide aggregation

The failed backup roll was installed in the lower position of a 3500 mm Steckel mill during its second commissioning. During mill spring testing, an abnormal noise occurred followed by discovery of the fracture. The rolling force recorded at fracture was 26.36 MN per side, below the test requirement of 29.4 MN per side. The spring test procedure was fully automated with no recorded abnormalities.

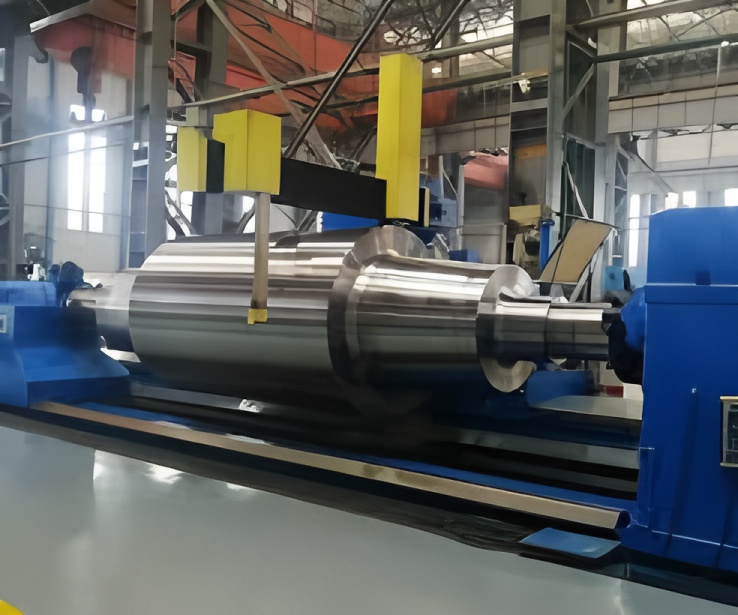

The backup roll material was 3% CrMoV steel with body dimensions of 1950mm×3450 mm. The finished product weighed 115.25 t from an original 227 t ingot. The roll had passed ultrasonic testing before installation. Subsequent analysis was conducted on the remaining portion to determine the failure cause.

1. Macroscopic Fracture Examination

The fracture occurred approximately 1315 mm from the drive end, perpendicular to the roll axis with a relatively straight fracture surface (Figure 1). The fracture initiation point was located about 305 mm from the center (Figure 2).

2. Manufacturing Process

The production process included: electric furnace melting → vacuum refining → vacuum casting → forging → post-forging heat treatment → rough machining with UT → final heat treatment → finish machining with UT → shipping.

3. Metallurgical Analysis

3.1 Macro-etching Examination

Three distinct defect regions were identified (Figure 3):

Region A: Dark spot segregation 80-180 mm from surface (Figure 4)

Region B: Light spot segregation 200-510 mm from center (Figure 5)

Region C: Light network defects within 250 mm from center (Figure 6)

3.1.1 Region A Analysis

Contained multiple non-metallic inclusions including titanium nitride, manganese sulfide, silicon oxide, alumina, and complex oxide slag rich in C, Al, Mg, Ca, Si, Cr, Na, Cl, Mn, S.

3.1.2 Region B Analysis

Comprised aggregates of Cr-Mo-V rich carbides and Cr-Si-S-C rich oxides centered around pores or voids, with elevated oxygen content detected.

3.1.3 Region C Analysis

Consisted of network segregation containing Fe-Cr-Mo rich carbides and Fe-Cr-C rich oxides.

3.2 Fracture Origin Analysis

Metallographic examination revealed:

Unevenly distributed gray-white segregation zones

Visible grain boundaries with fine troostite-pearlite structure in segregation areas

Coarse troostite-sorbite-pearlite matrix structure in other regions

Numerous non-metallic inclusions near grain boundaries (Figures 7-8)

SEM observation confirmed various inclusions and overheated structure indications (Figures 9-10)

Impact and tensile specimens exhibited cleavage brittle fracture characteristics with large TiN inclusions present (Figures 11-12).

4. Failure Mechanism Analysis

The fracture resulted from three primary factors:

(1) Uneven Carbide Distribution

White spot and network segregation from original ingot solidification

Inadequate forging and post-forging annealing failed to redistribute carbides

Resulted in uneven grain size distribution and localized coarse structures

(2) Non-metallic Inclusions

Multiple inclusion types throughout the cross-section:

Large TiN and TiC particles with sharp edges

Elongated MnS stringers

Low-melting point slag aggregates

Various oxide particles

Inclusion accumulation severely reduced alloy plasticity and caused stress concentration

Fracture originated from skin-related inclusion clusters

(3) Residual Stress

Significant thermal stress from uneven heating/cooling of large roll

Structural stress from heterogeneous microstructure

Stress concentration at inclusion/carbide clusters exceeded material fracture toughness

5. Conclusion

The backup roll fracture resulted from combined effects of high residual stress and severe accumulation of inclusions and carbides. The coarse microstructure, brittle phase aggregation, and multiple inclusion types reduced fracture resistance, initiating cracks that propagated through cleavage brittle fracture mechanisms.