In the highly demanding environment of modern steel production, the performance and longevity of rolling mill rolls are paramount. The relentless pursuit of enhanced product quality, improved rolling efficiency, and reduced operational costs has driven significant innovation in roll material science. Among these advancements, High-Speed Steel (HSS) rolls have emerged as a superior solution, offering a remarkable combination of properties that outperform conventional roll materials in many critical applications.

This article explores the technological progress in HSS rolls, detailing their fundamental advantages, analyzing key manufacturing process improvements, and providing insights into their application and performance. From the finishing stands of hot strip mills to high-speed wire rod mills, HSS roll technology is setting new benchmarks for durability and precision.

Understanding High-Speed Steel (HSS) Rolls

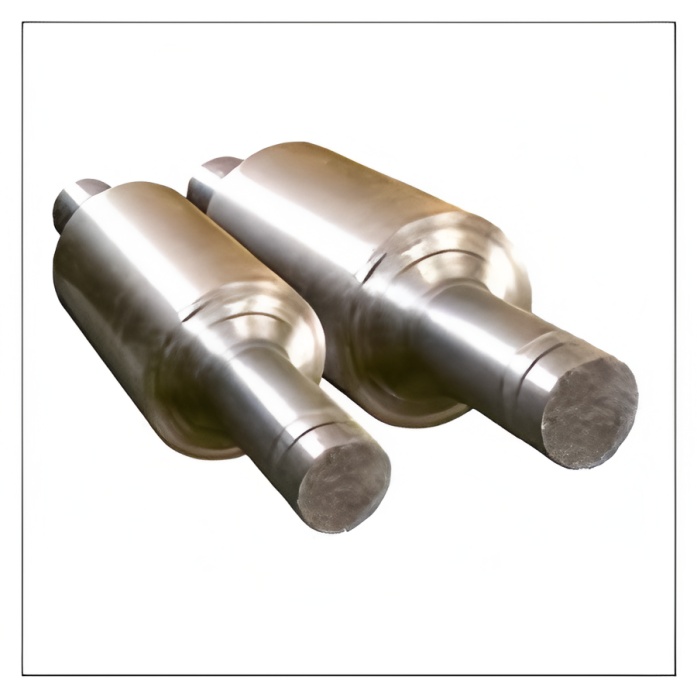

High-Speed Steel rolls are composite rolls featuring a highly alloyed outer shell metallurgically bonded to a more ductile and tough core. The defining characteristic of the HSS work roll material is its unique microstructure, which is engineered for extreme performance at both ambient and elevated temperatures.

Microstructural Composition

The microstructure of the HSS shell typically consists of:

- Primary Carbides: Extremely hard carbides like MC (Vanadium Carbide) and M₆C (Tungsten/Molybdenum Carbide) are embedded within the matrix. These carbides provide the primary source of wear resistance.

- Matrix: The carbides are suspended in a matrix of tempered martensite and a controlled amount of retained austenite. This matrix provides high thermal stability, toughness, and resistance to thermal cracking.

- Secondary Hardening: During the tempering process, numerous fine alloy carbides precipitate, causing a secondary hardening effect. This phenomenon raises the decomposition temperature of the martensite, significantly enhancing the roll’s red-hardness and ability to maintain its properties at high rolling temperatures.

Key Advantages of HSS Rolls Over Conventional Materials

Compared to traditional roll materials such as Adamite steel or Indefinite Chilled Double Poured (ICDP) iron, HSS rolls offer a suite of compelling advantages that translate directly to improved mill performance.

- Exceptional Wear Resistance: The high volume of hard primary carbides results in significantly lower wear rates, leading to longer rolling campaigns and reduced cost-per-ton of steel produced.

- Superior Surface Finish: Due to their slow wear and high hardness, HSS rolls maintain their surface roughness and profile for longer periods, resulting in a more consistent and higher-quality surface on the rolled product.

- Excellent Red-Hardness: The secondary hardening mechanism allows HSS rolls to retain high hardness and strength even at the elevated temperatures encountered in hot rolling, preventing thermal softening and rapid wear.

- High Thermal Crack Resistance: The tough matrix and optimized alloy design give HSS rolls excellent resistance to the initiation and propagation of thermal cracks (fire-cracking), a common failure mode in hot rolling.

- Improved Accident Durability: Despite their high hardness, modern HSS rolls possess sufficient toughness to better withstand mill accidents like cobbles and strip-welding, reducing the risk of catastrophic roll failure (spalling or breakage).

Innovations in HSS Roll Manufacturing Processes

The production of high-quality cast HSS rolls is a complex metallurgical process. Continuous research and development have led to significant process improvements aimed at overcoming inherent manufacturing challenges.

1. Optimizing Heat Treatment for Core Strength and Surface Hardness

A primary challenge is balancing the high quenching temperatures (often >1100°C) needed for the HSS shell’s wear resistance with the need to preserve the toughness of the ductile iron core. Excessive heat can coarsen the core’s microstructure or even cause localized melting, compromising its strength and increasing the risk of roll breakage.

Solution: Advanced Quenching Techniques. Surface induction quenching, particularly using a double-inductor process, has proven to be a highly effective solution. This method involves:

- Rapidly heating only the outer HSS layer to the required austenitizing temperature.

- The core material remains at a much lower temperature, preserving its optimal microstructure and mechanical properties.

- This energy-efficient process achieves high surface hardness without sacrificing the roll’s overall integrity.

2. Enhancing Core-Shell Bonding Strength

In traditional centrifugal casting, the interface between the HSS shell and the ductile iron core can be a weak point. Element migration and differences in solidification can lead to the formation of brittle phases (chill formation) or graphitization degradation, increasing the risk of delamination or “spalling” during service.

Solution: The Intermediate Layer Technique. To create a more robust and resilient bond, manufacturers have introduced an intermediate transition layer between the core and shell. Graphite steel is an ideal material for this purpose. Its properties act as a bridge between the two dissimilar materials, improving metallurgical fusion and reducing interfacial stress. This results in a composite roll with superior integrity and resistance to separation.

3. Mitigating Casting Cracks and Defects

The high concentration of alloying elements in HSS reduces its thermal conductivity. This leads to uneven cooling during casting, generating high residual stresses. Combined with element segregation and stresses from phase transformations, this elevates the risk of crack formation.

Solutions: Process Control and Modification.

- Molten Steel Modification: Inoculating the molten HSS with specific agents or adding rare earth elements helps refine the grain structure and distribute carbides more uniformly, reducing internal stress.

- Optimized Casting Parameters: Precisely controlling the rotational speed during centrifugal casting helps ensure a uniform shell thickness and minimizes stress concentration.

- Advanced Mold Coatings: Using dual-layer mold coatings, with an inner refractory layer and an outer insulating layer, helps to manage the cooling rate, promoting more uniform solidification and reducing thermal shock.

Typical Technical Specifications of HSS Rolls

To provide a clearer picture of their capabilities, the table below outlines typical parameters for high-performance HSS work rolls. These values can be customized by mill roll manufacturers based on specific application requirements.

| Parameter | Typical Value / Composition |

|---|---|

| Shell Hardness | 80 – 92 HSc (Shore C) |

| Chemical Composition (Shell, %) | C: 1.5-2.5, Cr: 4-10, Mo: 3-8, V: 4-9, W: 3-7 |

| Carbide Type | MC, M₂C, M₆C |

| Carbide Volume | 15 – 25% |

| Matrix Microstructure | Tempered Martensite + Retained Austenite |

| Core Material | Nodular (Ductile) Graphite Iron or Forged Steel |

| Core Tensile Strength | > 450 MPa |

| Primary Applications | Hot Strip Mill (Finishing Stands), Plate Mill, Wire Rod & Bar Mill (Pre-finishing/Finishing) |

Conclusion: The Future of Rolling Mill Roll Technology

The development and refinement of High-Speed Steel roll technology represent a critical step forward in meeting the stringent demands of modern metal rolling. By offering superior wear resistance, thermal stability, and surface quality, HSS rolls enable steel producers to achieve longer campaign lives, reduce downtime for mill roll grinding and changes, and produce higher quality products more economically.

As metallurgical engineers and roll manufacturers continue to innovate—improving heat treatment, bonding techniques, and casting processes—the performance and reliability of HSS rolls will only increase. This ongoing progress ensures that HSS will remain the material of choice for the most demanding work roll and backup roll applications for the foreseeable future, driving efficiency and quality across the global steel industry.