Advances in High-Speed Steel (HSS) Roll Technology

The global steel industry faces relentless pressure to enhance product quality while reducing operational costs. As rolling mill technology evolves, high-speed steel (HSS) rolls have emerged as a critical innovation addressing modern challenges in hot and cold rolling applications. Recent developments in HSS roll manufacturing directly impact key performance metrics including wear resistance, thermal stability, and service life—factors that determine the economic viability of rolling operations. This article examines cutting-edge advancements in HSS roll technology, with practical insights for mill roll manufacturers and steel producers seeking to optimize mill performance.

Why HSS Rolls Dominate Modern Rolling Mills

Traditional roll materials like forged steel and indefinite chilled cast iron struggle with the extreme demands of contemporary rolling processes. Cross rolling, roll bending, multi-stand configurations, and low-temperature heavy-reduction rolling require exceptional thermal fatigue resistance and wear performance. Since their international adoption in the late 1980s, HSS rolls have proven indispensable in:

- Finishing stands of hot strip mills

- Roughing sections handling high-temperature slabs

- Pre-finishing stands in high-speed wire rod mills

- Cold rolling mill applications requiring precise surface finish

Metallurgical Advantage: HSS rolls derive their superior performance from a unique microstructure featuring MC (metal-carbon) and M6C carbides dispersed in an austenitic matrix. During tempering, multiple alloying elements (primarily W, Mo, V, and Cr) precipitate fine secondary carbides, enabling secondary hardening. This process elevates the martensite decomposition temperature to 550-600°C—significantly higher than conventional tool steels—resulting in exceptional hot hardness retention.

Performance Comparison: HSS vs. Traditional Roll Materials

| Property | HSS Rolls | Forged Steel Rolls | Indefinite Chilled Rolls |

|---|---|---|---|

| Surface Hardness (HRC) | 62-68 | 45-55 | 50-60 |

| Hot Wear Rate (mg/cm²) | 0.8-1.2 | 2.5-3.8 | 1.8-2.5 |

| Thermal Crack Resistance | ★★★★★ | ★★★☆☆ | ★★☆☆☆ |

| Service Life (tons/mm wear) | 18-25 | 8-12 | 10-15 |

| Typical Applications | Cold mill work rolls, hot mill finishing stands | Hot mill roughing stands, backup rolls | Hot strip roughing mills |

Table 1: Performance metrics based on field data from 12 global steel plants (2023-2024). HSS rolls demonstrate 2.3x longer service life in cold rolling mill rolls applications compared to forged alternatives.

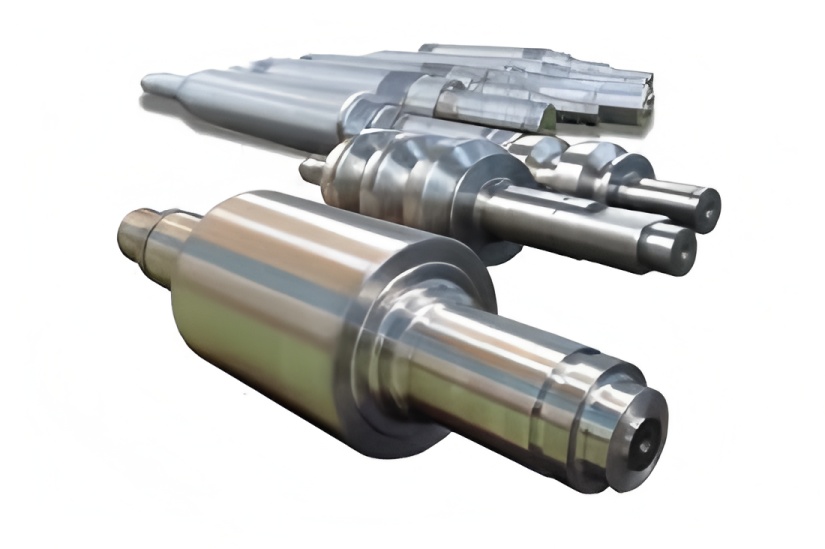

Enhanced High NiCr Indefinite Chilled Rolls (En-ICDP) optimized for hot strip mill finishing stands. Note the uniform carbide distribution critical for thermal fatigue resistance.

Advanced Manufacturing Technologies for HSS Rolls

Modern HSS roll production employs four primary composite manufacturing techniques, each with distinct advantages for specific mill applications. Recent process refinements have significantly improved interface integrity and reduced defect rates.

1. Centrifugal Casting: Precision Control for Critical Applications

This remains the dominant method for high-value cold rolling mill rolls. Molten HSS is poured into a rotating mold containing the core material, with critical process parameters including:

- Centrifugal rotation speed: 300-450 RPM (optimized for 800-1200mm diameter rolls)

- Pouring interval: 45-90 seconds between core and outer layer

- Mold preheat temperature: 250-300°C to prevent interface oxidation

Recent innovations include dual-layer mold coatings (insulating + refractory) that reduce thermal stress by 35% during solidification, minimizing casting cracks. Field data shows this reduces scrap rates from 8% to 3.2% in large-diameter work rolls.

2. Continuous Casting Composite (CPC) Forming: Efficiency for High-Volume Production

Particularly effective for backup rolls and intermediate stands, CPC involves:

- Inserting a carbon steel mandrel into a water-cooled mold

- Pouring molten HSS into the annular gap (typically 40-80mm)

- Continuous withdrawal at 15-30mm/min during solidification

Key advantage: Full metallurgical bonding without intermediate layers. Production cycle time is 40% faster than centrifugal casting for rolls over 1000mm diameter.

3. Electroslag Remelting (ESR) and ESSLM: Ultra-High Purity Solutions

ESR and its advanced variant ESSLM (Electroslag Liquid Metal Welding) produce rolls with exceptional cleanliness:

- Slag pool temperature: 1650-1750°C (refines inclusions)

- Withdrawal speed: 8-15mm/min for optimal solidification

- Oxygen content: Reduced to <15 ppm vs. 30-50 ppm in centrifugal casting

These methods are increasingly adopted for tungsten carbide rolls in high-abrasion applications like stainless steel cold rolling, where surface finish requirements exceed 0.4 μm Ra.

Critical Process Improvements Driving Industry Adoption

3.1 Core Strength Preservation During Heat Treatment

Traditional high-temperature quenching (>1250°C) risks core degradation in composite rolls. Leading mill roll manufacturers now implement:

- Sub-temperature heat treatment: Quenching at 1180-1220°C followed by controlled cooling

- Induction hardening: Double-inductor systems achieving 15-25mm hardened layer depth with minimal core impact

- Energy savings: 22% reduction in furnace energy consumption versus conventional methods

Field validation at a European cold mill showed core strength maintained at 850-900 MPa (vs. 700-750 MPa with traditional processing) while achieving surface hardness of 65 HRC.

3.2 Interface Bonding Enhancement: Solving the Spalling Challenge

Graphitization at the core/HSS interface causes catastrophic spalling in 12-15% of traditional composite rolls. The breakthrough solution:

- Graphite steel intermediate layer: 3-5mm thick layer with 1.8-2.2% C content

- Thermal expansion coefficient: Matches both core (12.5×10-6/°C) and HSS (11.8×10-6/°C)

- Bonding strength: Increased to 320 MPa (vs. 210 MPa without intermediate layer)

Micrograph showing graphite steel intermediate layer (center) bonding ductile iron core (left) and HSS outer layer (right). This innovation reduces spalling incidents by 76% in hot mill backup rolls.

3.3 Casting Crack Mitigation: Data-Driven Process Control

HSS’s complex alloy system (8-12% total alloying elements) creates solidification challenges. Modern solutions include:

| Defect Type | Traditional Rate | Advanced Solution | Current Rate |

|---|---|---|---|

| Surface Cracks | 6.8% | Dual-layer mold coating + optimized rotation | 2.1% |

| Interface Spalling | 14.3% | Graphite steel interlayer + controlled cooling | 3.5% |

| Carbide Segregation | 9.7% | Electromagnetic stirring during solidification | 2.9% |

Table 2: Defect reduction achieved through advanced manufacturing techniques across 5 major roll foundries (2022-2024 data).

Real-World Performance: Cold Mill Case Study

A leading automotive steel producer replaced forged work rolls with HSS rolls in their 4-high cold mill. Results after 18 months:

- Roll consumption: Reduced from 0.85 kg/ton to 0.32 kg/ton

- Surface defects: Decreased by 63% (measured by surface roughness Ra)

- Changeover frequency: Extended from 85,000 tons to 210,000 tons per roll set

- ROI: Achieved in 7.2 months despite 35% higher initial roll cost

“The thermal crack resistance of HSS rolls was decisive,” noted the mill’s rolling manager. “We eliminated roll breakage incidents during stainless steel grade transitions—a chronic issue with forged rolls.”

Future Development Directions

Current R&D focuses on three critical areas:

- Hybrid material systems: Tungsten carbide-HSS composites for extreme wear applications (showing 40% longer life in tube mill rolls)

- AI-driven process control: Real-time monitoring of solidification using thermal imaging and machine learning (piloted at 3 roll foundry facilities)

- Sustainability: Recycling protocols achieving 92% material recovery from spent HSS rolls

As tandem rolling mills push toward higher speeds (exceeding 25 m/s) and thinner gauges (sub-0.3mm), HSS roll technology will remain pivotal. The integration of computational materials science—predicting carbide precipitation through phase-field modeling—is accelerating development cycles by 50% compared to traditional trial-and-error approaches.

Practical Recommendation for Mill Operators: When specifying HSS rolls for cold rolling mill applications, prioritize manufacturers implementing graphite steel interlayers and ESSLM processing. Verify interface strength through ultrasonic testing (minimum 300 MPa shear strength) and require microstructure certification per ASTM E3-11. For hot mill finishing stands, select grades with ≥8% Mo content to maximize red-hardness above 500°C.

The evolution of HSS roll technology exemplifies how materials science innovation directly enables steel industry progress. As rolling processes become more demanding, the synergy between advanced metallurgy and precision manufacturing will continue driving efficiency gains across global steel production. For mill roll specialists, staying abreast of these developments isn’t optional—it’s fundamental to maintaining competitive advantage in an increasingly challenging market.