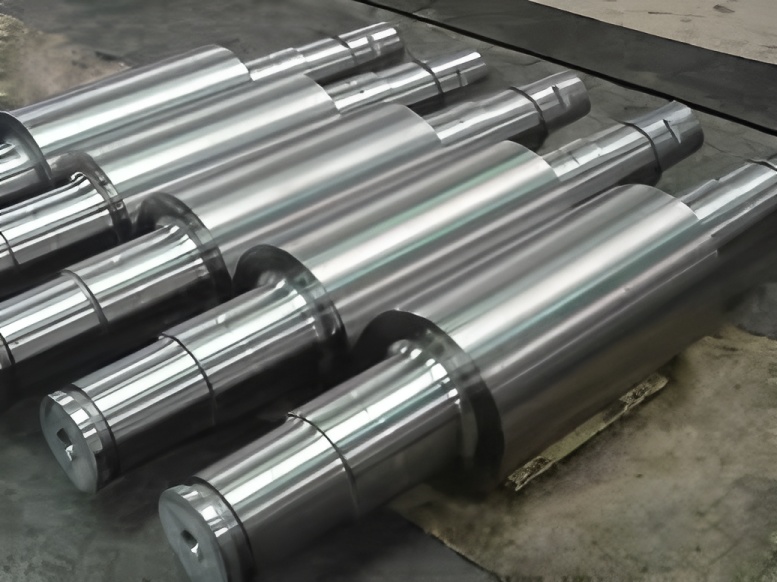

Steel mill rolls are in direct contact with steel strips and serve as vital tools in hot rolling production. Reducing roll consumption can effectively lower production costs and increase benefits, while also improving mill operation rates and ensuring the surface quality of hot-rolled products. In the production of hot-rolled steel strips, roll consumption is particularly significant. Therefore, identifying measures to reduce roll consumption and extend roll life is of great importance to hot-rolled steel strip production.

Optimizing Roll Changing Cycles to Minimize Wear

One of the most effective strategies for reducing steel mill roll wear is optimizing the roll changing cycle based on actual wear patterns rather than using a fixed schedule. This approach not only extends roll life but also maintains product quality and reduces operational downtime.

Roughing Rolls

The original roughing roll changing cycle was set between 2.5–3.8 thousand metric tons (wt). Through systematic monitoring of roll wear, strip shape, and surface quality, the cycle has been gradually extended. The current optimized cycle is stabilized at 3.8–4.5 wt, which shows no adverse impact on strip geometry or surface finish while significantly extending roll service life by up to 18%.

Finishing Rolls (F1–F7)

Due to varying rolling speeds across stands F1 through F7, backup rolls experience non-uniform wear. The previous “one-size-fits-all” changing cycle of 10–15 wt was inefficient. A segmented, stand-specific strategy has now been implemented:

| Stand | Original Cycle (wt) | Optimized Cycle (wt) | Rolling Volume Increase |

|---|---|---|---|

| F1–F2 | 10–12 | 13–15 | +12.3% |

| F3–F4 | 12–14 | 15–17 | +14.1% |

| F5–F7 | 14–15 | 16–18 | +18.7% |

Since adopting this segmented roll changing strategy, the total rolling volume per roll set has increased by approximately 14.94%. Additionally, statistical process control data confirm a notable reduction in wave defects—especially when rolling thin-gauge (<1.5 mm) products near the end of the roll’s service life.

Correct Handling of Rolling Accidents to Prevent Premature Roll Failure

Rolling accidents such as stockouts, steel sticking, or tail whipping are major contributors to accelerated roll wear and unexpected roll changes. Proper emergency protocols can mitigate damage and preserve roll integrity.

Stocking Accident Protocol

- Immediately stop cooling water to prevent thermal shock.

- Lift the upper work roll to avoid contact with the trapped strip.

- After strip removal, change the roll if severe cracking is observed.

- If immediate replacement isn’t feasible, idle the work roll for 5–10 minutes without cooling water to allow uniform temperature diffusion—this prevents crack propagation.

Steel Sticking Accident Response

When steel adheres to the roll surface due to high friction or lubrication failure:

- Remove all adhered material carefully using non-impact tools to avoid surface gouging.

- Perform non-destructive testing (NDT): magnetic particle inspection (MPI) for cracks and ultrasonic hardness mapping.

- Grind only the affected zone to a depth that eliminates all defects—typically 1.5–3.0 mm depending on severity—avoiding excessive material removal.

- Re-profile the roll edge with a 2–3 mm chamfer to redistribute contact stress.

Innovative Grinding and Repair Techniques for Common Roll Defects

Timely and precise repair of roll defects after incidents is critical to maximizing roll reuse and minimizing scrap rates.

Hot Cracks

Cause: Rapid thermal cycling during stockouts or piling accidents.

Solution: For R1 and F1–F4 work rolls, minor hot cracks often self-heal under stable rolling conditions. Closed cracks do not propagate and gradually disappear over 2–3 rolling cycles. Online monitoring via infrared thermography is recommended to track crack closure.

Roller Steel Sticking

If adhered steel exceeds 3 mm in thickness or shows layering, the roll must be removed from service. Post-removal inspection should include:

- Surface crack detection (dye penetrant or MPI)

- Hardness verification (Rockwell C scale; target: 58–65 HRC for forged work rolls)

- Grinding depth calculation based on defect depth + 0.5 mm safety margin

Peeling at Work Roll Edge

Cause: Stress concentration at the roll shoulder due to improper chamfer design or excessive crown.

Remedy: Since the shoulder doesn’t contact the strip, remove the peeled layer and re-grind with an optimized chamfer (typically 45° × 3–5 mm). Pair this with support roll end relief adjustments to improve load distribution.

Backup Roll Defects

Backup rolls, though not in direct contact with the strip, suffer from edge chipping and mid-body spalling due to cyclic loading. Conventional grinding often exacerbates stress risers.

Best Practices:

- Increase end chamfer length from 10 mm to 15–20 mm during grinding.

- For localized edge damage, use an angle grinder with 80–120 grit flap discs to smooth transitions before final precision grinding.

- For mid-roll pits or spalls, grind to full depth, then feather the edges over 20–30 mm to eliminate sharp boundaries.

Advanced Process Controls to Reduce Roll Wear

Roll Profile Optimization

Replacing traditional concave profiles with HVC (High Variable Crown) rolls in F1–F4 stands has proven highly effective. Additionally, increasing the negative crown on F5–F7 finishing rolls improves contact stress distribution:

- F1–F4: Switched from -0.15 mm concave to HVC profile (variable crown 0 to -0.30 mm)

- F5–F7: Negative crown increased from -0.10 mm to -0.25 mm

This modification enhances strip crown control, reduces edge wear by 22%, and decreases roll consumption by 9.5% across the finishing train.

Additional Proactive Measures

- Operator Training: Conduct quarterly workshops on accident response protocols to minimize human-induced roll damage.

- Inspection Standards: Implement ISO 9001-aligned roll acceptance criteria, including surface roughness (Ra ≤ 0.8 µm), roundness tolerance (≤ 0.02 mm), and hardness uniformity (±2 HRC).

- Material Selection: Partner with reputable mill roll manufacturers like HANI to source custom-engineered rolls. For front stands (F1–F3), consider high-speed steel (HSS) or tungsten carbide composite rolls for superior wear resistance.

- Roll Shop Integration: Use CNC roll grinders with adaptive path control to maintain optimal profile accuracy after each repair cycle.

Conclusion: A Holistic Approach to Roll Life Extension

The integration of optimized roll changing cycles, scientific accident response procedures, precision grinding techniques, and advanced roll profile design collectively delivers substantial reductions in steel mill roll wear. Real-world implementation at multiple integrated steel plants has demonstrated:

- Average roll life extension of 15–20%

- Reduction in roll consumption by 12–18%

- Improved surface quality (defect rate down by 30%)

- Lower labor intensity in roll shops due to fewer emergency interventions

For long-term sustainability, mills should prioritize collaboration with specialized rolling mill roll manufacturers who offer material science expertise, lifecycle support, and data-driven roll management systems. Whether using forged steel work rolls, cast iron backup rolls, or advanced tungsten carbide composite solutions, the key lies in matching roll metallurgy and geometry to specific process conditions.

By adopting these evidence-based practices, steel producers can achieve significant cost savings while maintaining the highest standards in hot-rolled product quality.