Related Product: https://hanirolls.com/

The pickling and tandem rolling mill connects successive coils through welding machines in the entry section, enabling continuous strip operation. However, with a total length exceeding 1,000 meters from entry uncoiler to exit coiler, and numerous equipment components along the path, strip deviation frequently occurs. Although the production line is equipped with 8 CPC correction devices for automatic strip alignment, severe deviation often develops in loopers beyond the correction capability, forcing production speed reduction or even shutdown. This significantly impacts production output, product quality, and equipment safety. Therefore, analyzing strip deviation causes and implementing effective control methods is essential.

Causes of Strip Deviation

Strip deviation occurs when the strip moves away from the production line center toward one side of the rollers. Under ideal conditions with good strip shape, uniform thickness, even tension distribution, and properly aligned rollers, the strip runs centered. However, various factors in actual production disrupt this ideal trajectory.

Impact of Strip Defects

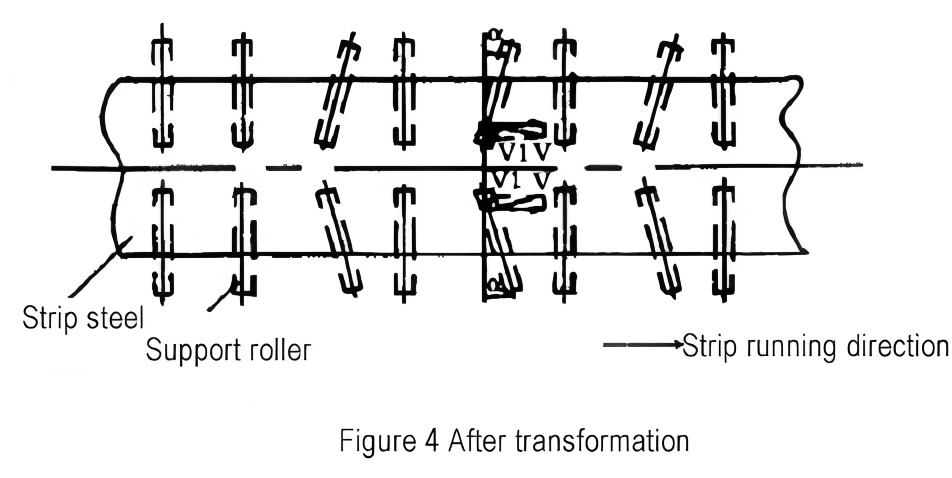

When strip thickness differs between sides, creating a sickle shape, deviation occurs. As shown in Figure 1(a), ideal operation is depicted in Figure 1(b), while Figure 1(e) illustrates left convex sickle bend condition. The deviation distance f = A’C × sinβ after the strip enters the steering roll. Similarly, right convex sickle bends cause rightward deviation. The deviation magnitude relates to sickle bend degree, steering roll spacing, and strip tension.

Other strip defects including center wave, edge wave, longitudinal bending, and transverse bending, combined with variations in width, thickness, hardness, and surface roughness, prevent even contact with steering rolls. These asymmetric factors generate lateral forces perpendicular to the running direction, causing lateral slippage and deviation.

Roller Influence

During manufacturing, rolls may be tapered, or develop tapered wear from strip edge waves, creating uneven tension distribution that pulls the strip toward the thicker end. The deviation amount correlates with taper degree.

Additionally, roll surface quality affects deviation, including uneven roughness, surface damage, oil contamination, etc. Severe cases cause strip slippage on steering rolls, further exacerbating deviation.

Other Influencing Factors

Additional factors like strip temperature variations, tension fluctuations, and equipment installation accuracy also contribute to deviation. These factors interact complexly, making accurate analysis challenging. Long-term observation reveals that increased strip tension reduces deviation when other conditions remain constant. Also, long free conveyance sections cause greater deviation than equivalent lengths with intermediate steering rolls.

Analysis and Solution for Looper Strip Deviation

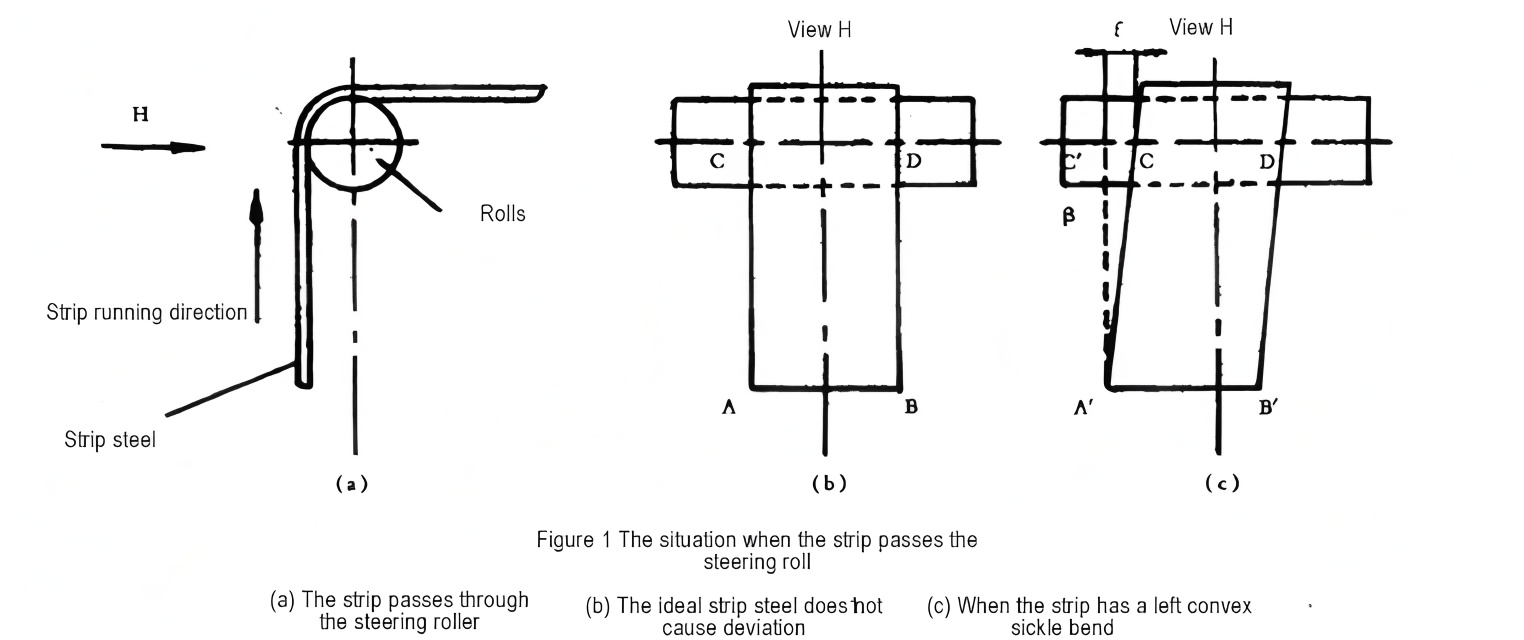

The 3# and 7# correction devices (±150mm range) align strip in entry and exit loopers. Observation reveals that the approximately 200-300 meter looper length with numerous support rollers causes progressively severe deviation beyond correction capability, triggering automatic production shutdown (Figure 2). Controlling looper deviation within correctable range ensures normal operation.

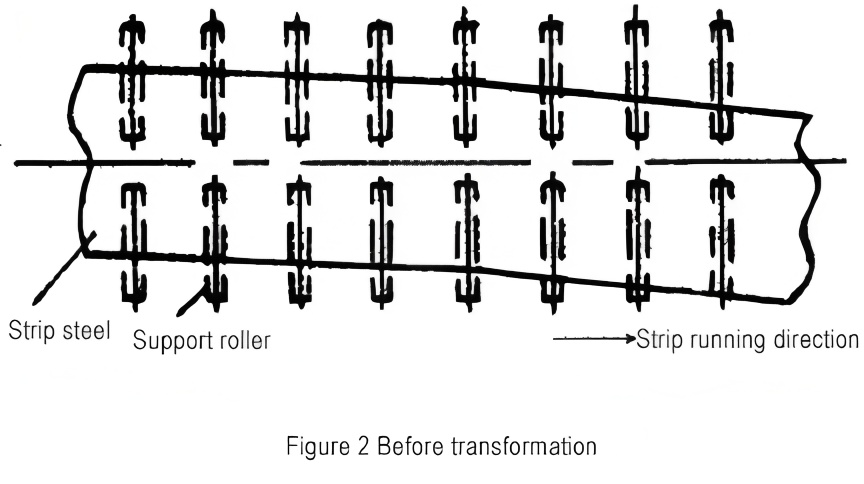

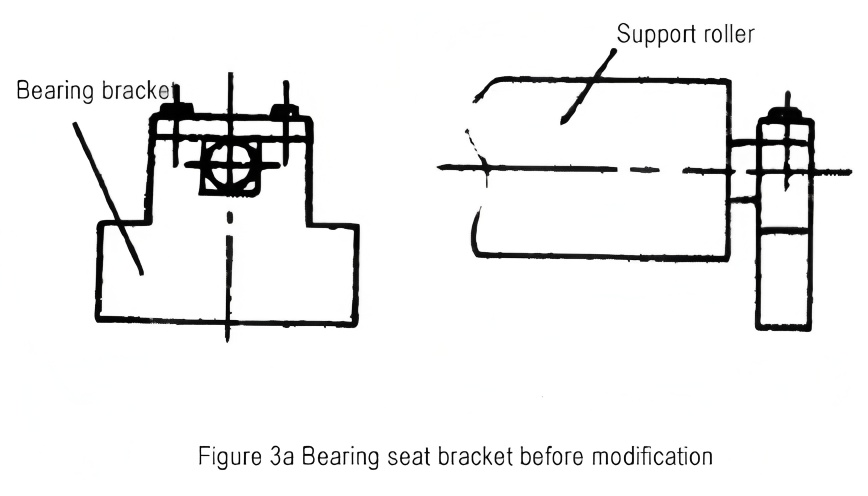

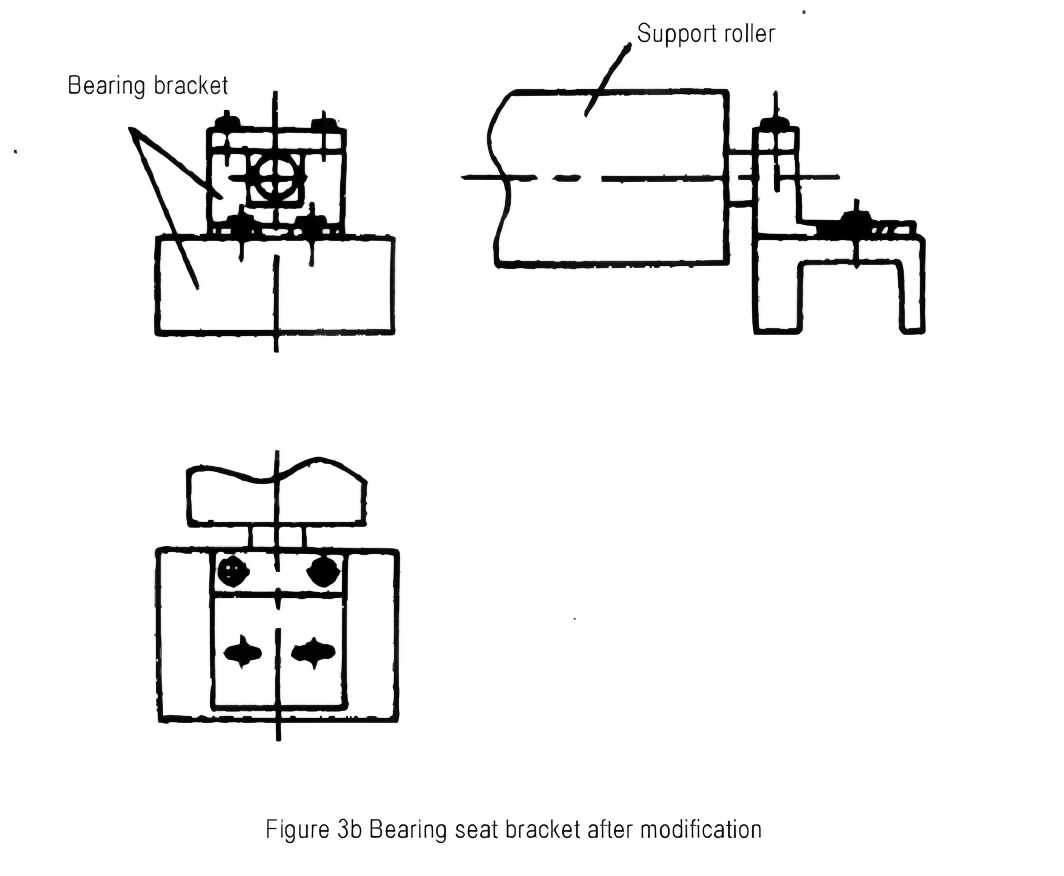

Originally, support roller bearing seat brackets were fixed and non-adjustable (Figure 3a). We modified these to include two elongated holes enabling roller adjustment (Figure 3b). This allows rotating originally perpendicular support rollers to specific angles, installing multiple pairs of V-shaped rollers in the looper. As shown in Figure 4, with roller surface velocity V, strip-roller friction generates lateral velocity component V1 = V × sinα, creating centering tendency that increases with angle and strip-roller contact area. This self-centering action significantly reduces looper deviation.

Conclusion

Pre-modification, looper deviation caused monthly production slowdowns or manual interventions, ranging from several to over a dozen occurrences, particularly frequent for strips thicker than 3.5mm. Post-modification, looper strip deviation has been effectively controlled within allowable limits. Since modification completion, no production stoppages have occurred due to strip deviation. The modification has successfully ensured safe, stable, high-speed production line operation.