This article describes methods for testing roll hardness, analyzes influencing factors, and proposes countermeasures.

Keywords: roll; hardness test; influencing factors; test method

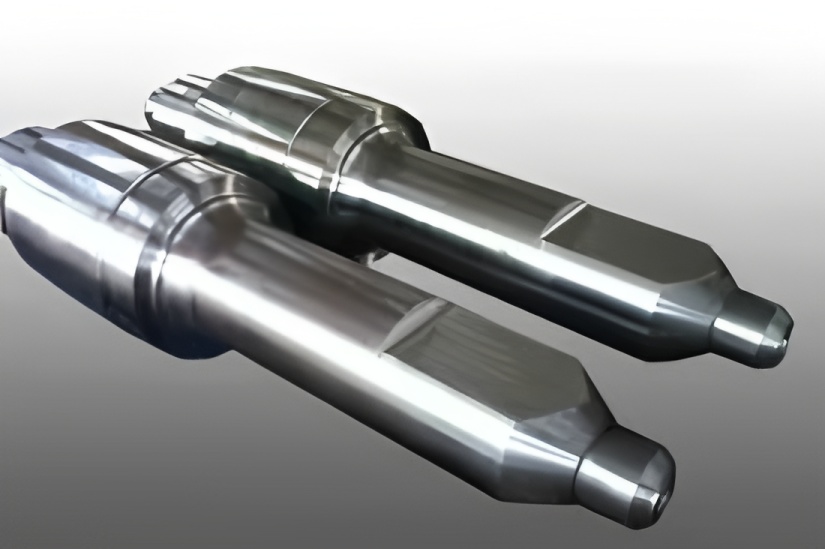

Rolls are indispensable tools in steel rolling production. Besides the material itself, hardness is the most critical technical indicator. For the same type of material, hardness often correlates with strength and toughness. Particularly for rolls, the hardness is closely related to microstructure, residual stress level, wear resistance, thermal crack resistance, and fatigue resistance. Compared to other testing methods, hardness testing is fast, cost-effective, and uses commonly available instruments. Therefore, both manufacturers and users consider hardness a key indicator for predicting roll performance and aim to achieve optimal rolling results by selecting rolls with the most suitable hardness.

Hardness testing is integral throughout roll production and usage. Manufacturers test during production and in the finished state to ensure compliance with technical requirements. Users inspect and monitor hardness upon receipt and during use to prevent rolling accidents or compromised product quality due to substandard hardness.

Influenced by factors such as human skill, equipment model, roll condition, testing standards, and environment, obtaining an accurate absolute hardness value is challenging. Discrepancies often arise between manufacturers and users when testing the same roll. Based on manufacturing and testing experience, this article analyzes reasons for deviations in test results.

Common Roll Hardness Testing Methods

Hardness refers to a material’s ability to resist indentation by a hard object. It is generally categorized into three types: scratch hardness, indentation hardness, and rebound hardness.

Whether using scratch hardness methods like Mohs hardness, indentation methods like Brinell, Rockwell, or Vickers hardness, or rebound methods like Shore or Leeb hardness, these are generally non-destructive for most components, leaving minimal marks. However, for rolls, even minor marks can cause damage. For instance, scratches may interfere with eddy current testing or initiate cracks leading to breakage or spalling. Therefore, scratch hardness testing is generally avoided for large rolls.

Rolls are large cast or forged products, commonly weighing several tons, with the largest backup rolls for wide heavy-plate mills reaching 240 tons. Such sizes preclude testing with conventional laboratory hardness testers. Thus, large rolls are tested using portable rebound hardness testers like Shore or Leeb hardness testers.

Shore Hardness

Shore hardness involves dropping a specific punch from a fixed height onto the test surface and measuring the rebound height to determine hardness.

C-type Shore Hardness Tester: A 2.5 g diamond punch with a 1.0 mm tip radius is dropped from 254 mm. The rebound height is measured, with 165.1 mm set as 100 HSC and the surface as 0 HSC. The scale is divided into 100 units, each 1 HSC.

D-type Shore Hardness Tester: A 36.2 g diamond punch with a 1.0 mm tip radius is dropped from 19 mm. The rebound height of 13.57 mm corresponds to 100 HSD, and the surface is 0 HSD. The scale is divided into 100 units up to 140 HSD.

For example, the quality inspection team of a major roll manufacturer uses both HSC and HSD testers. HSC relies on visual reading of rebound height, while HSD uses a dial indicator.

Leeb Hardness

Leeb hardness also uses rebound principles. A tungsten carbide punch (5.5 g, 1.5 mm tip radius) is propelled by spring force to impact the surface. Hardness is calculated based on the ratio of rebound to impact velocity:

HLD = 1000 × (Vr / Va)

Key differences from Shore hardness are:

The punch is spring-loaded for consistent initial speed.

Hardness is derived from velocity ratio rather than rebound height.

Unlike Shore testers, which require vertical orientation, Leeb testers allow angled measurements, reducing operator skill requirements. Most Leeb testers feature digital displays, minimizing subjective reading errors.

Main Factors Affecting Hardness Test Results

Obtaining accurate hardness is difficult due to multiple influencing factors, often causing discrepancies between manufacturers and users.

Effect of Hardness Conversion

Different hardness testers yield different results. The variety of hardness types and testers necessitates conversion between scales (e.g., Leeb to Shore, Vickers, or Rockwell). Most conversion tables are based on big data from roll manufacturers, varying by region and material. For example, GB/T 13313-2008 provides conversion between HSD and HLD for forged steel, cast steel, and cast iron. Table 1 compares different conversion tables for forged steel.

Table 1 Data Comparison of Different Hardness Conversion Tables (Forged Steel)

| Conversion Table | GB/T13313 | DAVY | RAVNE | OSB |

|---|---|---|---|---|

| HSD | 75 | 75 | 75 | 75 |

| HLD | 764 | 762 | 768 | 755 |

| HV30 | 615 | 593 | 616 | 580 |

None of these tables fully explain their derivation—whether from laboratory samples, big data, or regression calculations. Discrepancies in built-in conversion tables often cause disputes between producers and users.

Influence of Testing Apparatus and Test Block

(1) Hardness Tester Accuracy

The precision of the tester itself affects results. Accuracy varies among manufacturers and even among units from the same manufacturer. Calibration with standard test blocks is essential before roll testing.

(2) Calibration Block Hardness Range

The hardness range of the standard block significantly influences results. As shown in Table 2, using the same tester on blocks of different ranges yields different deviations. For example, Tester 2 shows Δ = -0.5 HSD at 60 HSD but Δ = -1.5 HSD at 90 HSD. Using a 60 HSD calibration for 90 HSD samples would underestimate hardness by 1 HSD.

Table 2 Calibration Comparison of Different Standard Blocks Using Different Hardness Testers

| Standard Block Hardness | Tester 1 Measurements | Tester 1 ∆ | Tester 2 Measurements | Tester 2 ∆ |

|---|---|---|---|---|

| 30 HSD | 29.5 | -0.5 | 30 | 0 |

| 60 HSD | 60.5 | +0.5 | 59.5 | -0.5 |

| 90 HSD | 91 | +1 | 88.5 | -1.5 |

Thus, calibration should use a standard block with hardness closest to the sample. Corrected values may still deviate from actual hardness.

Roll producers test a wide hardness range and use multiple standard blocks. However, rolling lines often have only one or two blocks. Operators may test different rolls or parts after a single calibration. For example, cold rolling work rolls exceed 95 HSD, while backup rolls are 65–70 HSD, and necks are 35–45 HSD. Using one block for such spans increases deviation risk.

(3) Cleanliness of the Punch

Contamination on the punch (e.g., dirt, debris) absorbs impact energy, reducing rebound speed/height and underestimating hardness. Experienced operators wipe the punch after each test. In one case, a mill reported low hardness; investigation found a stained punch. After cleaning, results were合格.

Influence of Roll Surface State

Hardness testing requires a clean, non-magnetic, oil-free, scale-free surface without rust-proof oil or coatings. Surface roughness Ra should be ≤ 3.2 μm for values ≤ 70 HSD, and ≤ 1.6 μm for >70 HSD. Common issues include:

(1) Oil Residue

Oil increases friction, reducing rebound speed/height and hardness readings. Table 3 shows tests on various rolls: point A had oil stains; B and C were clean areas (5-test average).

Table 3 Test Results of Roll Body Hardness (HSD) for Different Materials

| No. | Material | Standard Hardness | A (With Oil Stain) | B (Clean) | C (Clean) |

|---|---|---|---|---|---|

| 1 | Chilled Cast Iron | 77–83 | 76.2 | 78.3 | 79.4 |

| 2 | Chilled Cast Iron | 70–76 | 70.4 | 74.5 | 75.2 |

| 3 | High Cr Cast Iron | 75–80 | 74.3 | 76.2 | 76.7 |

| 4 | Cr3 Forged Steel | 60–65 | 52.2 | 61.2 | 61.8 |

| 5 | Cr5 Forged Steel | 65–70 | 66.4 | 67.2 | 67.0 |

Rolls are often coated with anti-rust oil—either thick yellow/brown soft film or thin transparent hard film. One manufacturer received complaints about low hardness; on-site inspection found that only spot wiping was done. After thorough cleaning, hardness tested合格.

(2) Residual Magnetism

External magnetic fields can magnetize rolls. This has minimal effect on Shore testers but may cause significant deviation with Leeb testers, which use electronic components sensitive to magnetic fields.

(3) Surface Roughness

Rough surfaces often lead to low hardness readings. Rolls for bar/wire rod mills are delivered in turned condition, while plate/strip mill rolls are ground. Turned surfaces are rougher; manufacturers often polish bright bands/spots before testing, but users may test in the as-turned state, yielding lower values.

Measures to Eliminate Hardness Differences

(1) During process design, roll producers should understand the hardness tester model/conversion table used by the customer. Ideally, use the same tester as the customer to avoid conversion discrepancies.

(2) Both producers and users should calibrate testers with appropriate standard blocks before testing. If readings fluctuate, clean the punch to remove contaminants.

(3) Clean rolls thoroughly before testing to remove oil, rust, etc. For Leeb testers, avoid magnetic interference; demagnetize if necessary. For turned surfaces, polish bright bands/spots to meet roughness requirements.

Conclusion

(1) Hardness testing is affected by equipment, calibration blocks, surface roughness, and cleanliness. These factors cause most discrepancies between manufacturers and users.

(2) Roll producers should not only consider their own testers and conversion tables but also calibrate against the customer’s equipment. Determine deviation values and adjust required hardness accordingly during production to minimize errors from tester or conversion differences.