Introduction

The cold rolling work roll is a critical component in cold rolling mills, characterized by complex manufacturing processes and harsh operating conditions. It endures various stresses including friction, thermal stress, and mechanical impact. During service, rolls may experience fractures, peeling, and wear, leading to failure that increases consumable costs and disrupts production, resulting in economic losses. During normal operation at a company’s stainless steel production line, sudden surface peeling on a cold rolling work roll caused equipment failure and shutdown, significantly impacting production. This study analyzes a peeling sample from the work roll through macroscopic fracture examination, spectral analysis, hardness testing, metallographic examination, and scanning electron microscopy to investigate the peeling causes.

1. Physical and Chemical Test Results

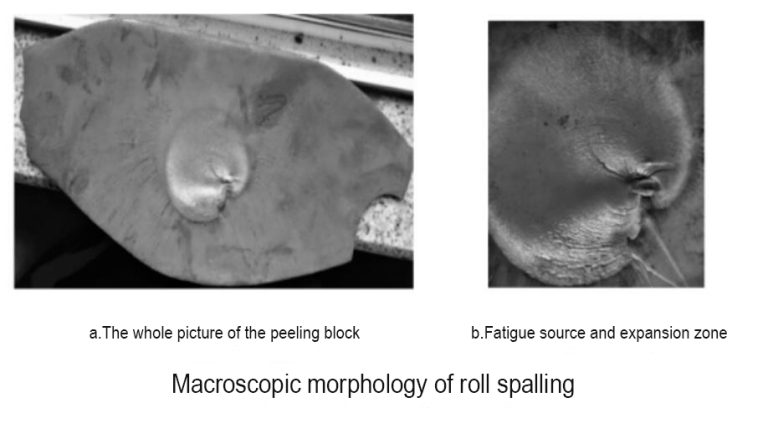

1.1 Peeled Block Fracture Observation

Macroscopic analysis of the peeled block reveals typical fatigue fracture characteristics (Figure 1). Visible shell patterns appear in the central circular area, indicating fatigue propagation. The convergence point of these patterns identifies the fatigue origin, located internally rather than at the roller surface. The outer ring area shows radial morphology characteristic of instantaneous fracture. Unlike static failures, fatigue failures often occur without warning signs, making them particularly detrimental.

1.2 Chemical Composition and Hardness

Spectroscopic analysis of samples from the peeled block confirms the roll material as 8Cr3NiMoV (Table 1). All elements meet GB/T1299-2014 standards except chromium, which is slightly below the lower limit. Rockwell hardness testing shows consistent values of HRC 64.5 across all sample locations, satisfying standard requirements.

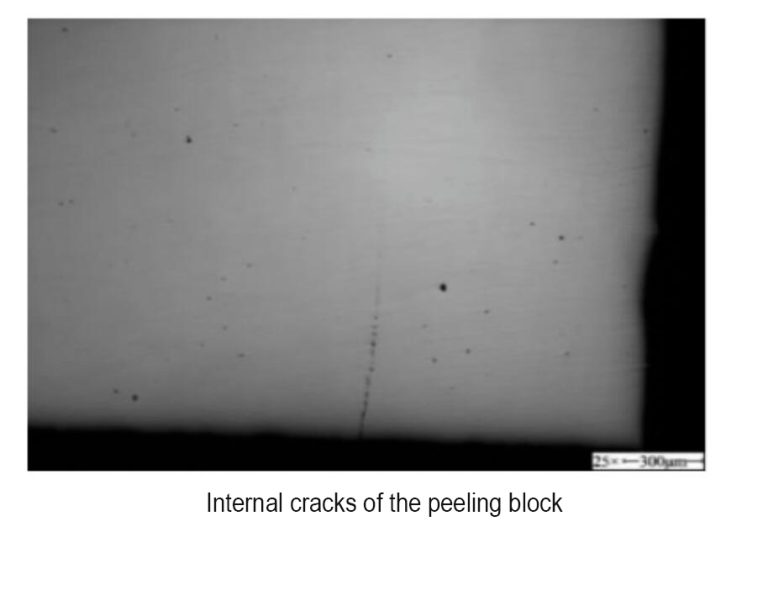

1.3 Metallographic Examination

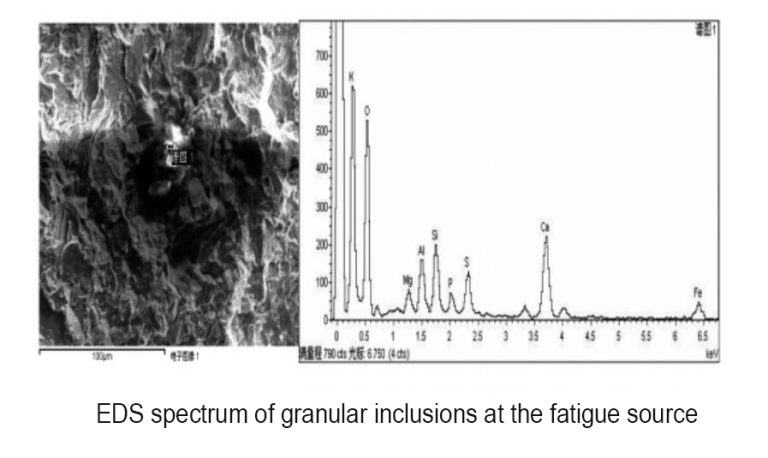

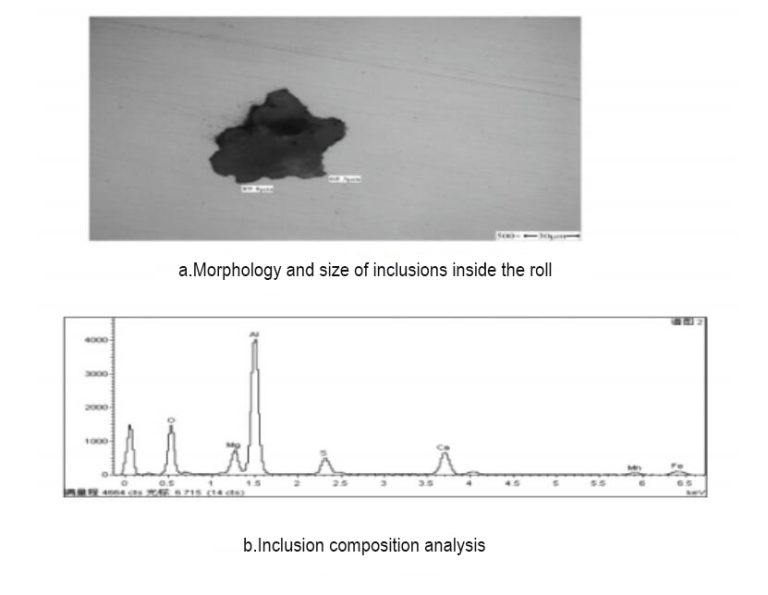

Metallurgical samples sectioned through the fatigue origin (approximately 8mm below the roll surface) reveal multiple root-like cracks propagating from internal fatigue sources toward the surface (Figure 3). Further examination identifies numerous blocky inclusions up to 90μm in size (Figure 4a), significantly exceeding acceptable limits. Energy dispersive spectroscopy (Figure 4b) shows these inclusions primarily contain oxygen and aluminum with minor elements including magnesium, sulfur, calcium, manganese, and iron, identifying them as Al2O3-based mixed inclusions, likely resulting from inadequate control during roll production.

2. Analysis and Discussion

2.1 Crack Formation Mechanism

Macroscopic analysis indicates roll peeling initiates from internal fatigue origins. Under continuous cyclic operational stress, cracks progressively expand forming shell patterns. When fatigue cracks reach critical dimensions, the remaining material cannot withstand rolling forces, leading to instantaneous fracture and surface peeling. During operation, rolling loads and localized contact create maximum combined shear stress in subsurface regions. Manufacturing processes introduce residual stresses, while operational friction generates thermal stresses. Strip-related issues like breakage, tail whip, overlapping, or slippage create localized overload and impact stresses. Non-metallic inclusions, acting as mechanical mixtures with significantly different properties from the steel matrix, disrupt material homogeneity and create stress concentration points that become fatigue origins. Differential thermal expansion between inclusions and matrix during heating generates additional stress fields. Under complex stress conditions, particularly with brittle inclusions, primary microcracks form at stress concentration points. With continued stress cycling, microcracks propagate through the matrix. When overall crack dimensions exceed critical thresholds, rapid unstable crack growth leads to instantaneous fracture and surface peeling.

2.2 Inclusion Effects on Fatigue Performance

Inclusion impact on fatigue life depends on their nature, size, quantity, and distribution. Brittle, blocky, or spherical inclusions with poor matrix bonding (such as TiN and Al2O3) are more detrimental than ductile, elongated inclusions. Clustered distributions or locations in high-stress regions significantly reduce fatigue life. The effect also varies with matrix properties: softer steels show minimal sensitivity, while higher-strength materials demonstrate increased vulnerability. Research indicates strong sensitivity between fatigue life and inclusion size. Reducing inclusion size significantly improves fatigue life. For high-hardness components, the critical surface inclusion size is 8-10μm, varying with hardness and depth. Below critical size, inclusion-induced fatigue fractures can be avoided; above critical size, fatigue properties deteriorate rapidly with increasing inclusion dimensions. Studies show that halving inclusion size in high-strength steel can increase fatigue life 100-fold and improve fatigue strength by 12-15%.

3. Conclusion

(1) Cold rolling work roll surface peeling results from fatigue fracture initiated at large Al2O3-type brittle inclusions near the surface.

(2) Enhance roll inspection protocols: ultrasonic testing for internal defects; magnetic particle and eddy current testing for surface defects. Apply appropriate methods individually or in combination to ensure roll quality.

(3) Establish scientific roll usage and maintenance systems to ensure proper cooling and lubrication during operation, preventing overheating.