High-speed steel (HSS) work rolls have become a key technological upgrade in hot-rolled strip production lines worldwide. Compared with traditional high-chromium cast iron rolls, HSS rolls offer superior wear resistance, higher hot hardness, better thermal fatigue resistance, and longer rolling campaigns. When properly designed, ground, lubricated, and inspected, they can significantly reduce roll consumption, improve hot strip surface quality, and lower overall production costs for modern hot strip mills.

This article systematically analyzes the application and enhancement of HSS rolls in hot-rolled strip finishing mills from a production engineering perspective. It covers roll material design, grinding optimization, lubrication strategies, inspection procedures, and PC/FC shape control tuning. It also provides practical data and parameters that can be referenced by mill roll manufacturers, steel rolling mill rolls users, and rolling mill roll specialists seeking to improve mill performance.

Typical related terms in this field include: mill roll, rolling mill rolls, hot rolling mill rolls, steel mill work rolls, forged and cast rolls, tungsten carbide composite rolls, and backup rolls. In this article, the focus is on HSS work rolls used in hot strip finishing stands.

Role of High-Speed Steel Rolls in Hot-Rolled Strip Production

In most modern hot strip mills, the finishing mill (F1–F7 stands) is where strip thickness, shape, and surface quality are finally controlled. Traditionally, the work rolls in the early finishing stands (F1–F2, sometimes F3) have been high-chromium cast iron. These rolls rely on the in-situ formation of a hard Cr2O3-rich oxide film on the roll surface during contact with the hot strip. This oxide layer provides wear resistance, but:

- Oxide formation is highly sensitive to cooling water distribution, rolling speed, and strip temperature.

- Unstable oxide layers can lead to localized spalling and strip surface defects (scratches, pits).

- Roll life is limited by severe thermal cracking and wear after relatively short campaigns.

High-speed steel rolls were introduced as a solution to improve work roll life and reduce surface defects. Their microstructure (high volume fraction of MC, M6C carbides in a martensitic or tempered martensitic matrix) gives them very high hot hardness and excellent wear resistance, independent of oxide film stability. As a result, HSS hot rolling mill rolls can sustain much longer campaigns with more stable strip surface quality.

Material Design and Improvement of High-Speed Steel Rolls

The performance of HSS rolls in hot strip finishing depends strongly on their chemical composition and matrix structure. Over the last decade, roll makers have optimized alloy design to balance wear resistance, thermal crack resistance, and toughness of the working layer while ensuring a safe metallurgical bond to the ductile iron or alloy steel core.

| Material | C (wt%) | Cr (wt%) | Mo (wt%) | V (wt%) | W (wt%) | Hardness (HSD) |

|---|---|---|---|---|---|---|

| Conventional high-Cr cast iron roll | 2.3–2.8 | 10–18 | 0.5–2.0 | <0.5 | <1.0 | 60–72 |

| Typical HSS work roll (HANI-type) | 1.8–2.4 | 3–6 | 4–6 | 4–6 | 3–6 | 80–90 |

The high content of strong carbide-forming elements (Mo, V, W, sometimes Nb) in HSS rolls leads to a dense dispersion of MC and M6C carbides, which remain stable at high temperature. By controlling solidification and subsequent heat treatment, manufacturers can create:

- A tempered martensitic matrix with good toughness and hot hardness.

- Uniform carbide distribution to minimize localized wear and reduce crack initiation sites.

- A defect-free metallurgical bond between the HSS shell and the ductile iron/alloy steel core.

In composite HSS rolls such as those produced by HANI, the shell–core interface is carefully engineered. A sound bond improves tensile strength and roll bending resistance, which directly benefits strip shape control in high-speed finishing mills.

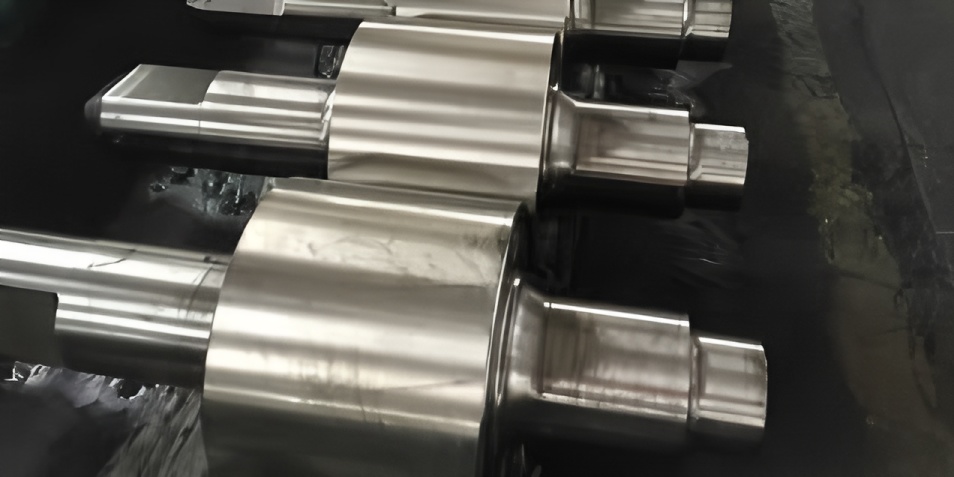

Superior Wear Resistance and Campaign Performance of HSS Rolls

Comparative production trials in hot strip finishing mills consistently show that rolling mill rolls made from HSS have significantly better wear resistance than high-chromium cast iron rolls under identical rolling schedules. Shutdown measurements of roll barrel diameter and profile confirm substantially lower wear on HSS rolls, even after long campaigns.

| Parameter | High-Cr Cast Iron | HSS Work Roll |

|---|---|---|

| Typical tonnage per mm wear (t/mm) | ≈ 4,000–5,000 | ≈ 100,000–130,000 |

| Relative tonnage/ mm (HSS / high-Cr) | 1 | 26–28 |

| Surface condition after campaign | Notable wear; deeper cracks | Minor wear; fine thermal checking |

| Typical regrinding depth | 0.5–1.0 mm | 0.1–0.3 mm |

In many mills, HSS rolls in the F1–F2 stands can be reused multiple times with minimal regrinding, which directly reduces:

- Roll manufacturing and purchase costs per ton of strip.

- Roll shop grinding time, wheel consumption, and energy use.

- Roll change frequency, contributing to higher mill availability.

HSS rolls also exhibit better resistance to thermal cracks than high-chromium cast iron. Production incidents such as brief cooling water fluctuations or short cobbles often leave only fine thermal check marks on the surface, which can be removed by shallow grinding. This robustness simplifies roll maintenance and reduces the risk of premature roll scrapping.

Friction Coefficient, Bite Conditions, and Rolling Force with HSS Rolls

One characteristic of HSS work rolls is their relatively high friction coefficient when contacting hot strip. Typical measured values for the coefficient of friction μ in hot finishing passes are:

| Roll Material | Friction Coefficient μ |

|---|---|

| High-chromium cast iron roll | ≈ 0.30–0.36 |

| HSS work roll | ≈ 0.40–0.44 |

A higher μ offers certain advantages and disadvantages:

- Improved bite conditions: HSS rolls in F1–F2 make it easier to bite thicker slabs and transfer higher reductions without slippage, especially at high rolling speeds.

- Higher rolling force and torque: The same friction increase tends to raise rolling force and power consumption if process conditions remain unchanged.

To fully benefit from HSS rolls while controlling force, mills typically adopt lubrication technology and fine-tune pass schedules, entry thickness tolerances, and coolant application patterns.

Grinding Optimization for High-Speed Steel Work Rolls

Due to their high hardness and abrasive carbides, HSS rolls present more severe challenges in the roll shop than conventional cast iron rolls. Common problems in mill roll grinding of HSS include:

- Low grinding efficiency and high wheel wear.

- Vibration marks and chatter on the roll surface.

- Difficulty in maintaining crown/profile within tight tolerances.

- Surface roughness outside target range, affecting strip roughness and friction.

To overcome these challenges, roll grinding shops have adopted a combination of optimized grinding wheel specifications and improved grinding parameters. A typical guideline is summarized below.

| Item | Recommendation for HSS Rolls |

|---|---|

| Grinding wheel type | Alumina or CBN wheel with high toughness grains |

| Wheel hardness | Medium to medium-hard (e.g. H–K) |

| Grit size | Roughing: 36–46; Finishing: 60–80 |

| Feed rate | 0.02–0.05 mm/pass (finishing) |

| Peripheral speed control | Periodic variable speed to avoid chatter frequencies |

| Target roughness Ra | Typically 0.6–1.2 μm (depending on stand and product) |

Advanced roll grinders also use online measurement and compensation systems to control the roll contour and taper, ensuring that tight flatness requirements are met after installation in the mill. Because HSS roll shells are expensive, grinding allowances must be carefully planned to maximize usable shell thickness while preserving a safety margin above the bond layer.

Lubrication Technology for HSS Work Rolls in Finishing Mills

To balance the higher friction coefficient of HSS rolls while preserving their good bite behavior, many hot strip mills implement oil lubrication systems in the finishing stands. These systems spray emulsified oil–water mixtures onto the roll–strip interface, forming a thin lubrication and protective film.

Properly designed lubrication can:

- Reduce rolling force and motor current, lowering energy consumption.

- Decrease roll wear, especially adhesive and abrasive wear.

- Dampen mill vibration, improving strip surface finish.

- Moderate roll surface temperature and reduce thermal gradients, thus mitigating crack formation.

In combination with HSS rolls, gap spraying and flexible flow control are often used:

- Gap sprays help to stabilize the oxide film and avoid local spalling on the roll surface.

- Reducing the roll surface temperature lowers the amplitude of thermal cycling and suppresses deep thermal crack formation.

For mills transitioning from high-Cr rolls to HSS, the introduction or optimization of oil lubrication is an effective way to obtain the benefits of HSS (wear resistance, shape control) without suffering from unacceptably high rolling force or power penalties.

Inspection and Non-Destructive Testing of HSS Rolls

Because high-speed steel shells are costly, and because HSS rolls are more sensitive to certain types of mechanical damage than to thermal cracking, rigorous inspection standards are essential to avoid catastrophic failures such as spalling or roll breakage. Typical incident scenarios include slab pile-ups, strip cobbles, and mechanical impacts from guides or mill equipment.

After any abnormal event, the following non-destructive testing (NDT) sequence is recommended before the roll is returned to the mill:

- Visual inspection: Identify obvious mechanical dents, gouges, or severe thermal cracks on the barrel and necks.

- Eddy current testing: Scan the roll barrel surface for surface-breaking and near-surface cracks. Eddy current is highly sensitive to small surface discontinuities.

- Ultrasonic testing: Examine the shell for internal defects and check the integrity of the shell–core bond region. This is crucial for composite HSS rolls.

- Surface wave or dye penetrant testing: Used locally in suspected regions to confirm and delineate crack extent.

Any detected cracks must be fully removed by grinding. The depth of the defect determines whether the roll is still within the safe grinding allowance. If the crack approaches the bond layer or core material, the roll is normally scrapped to avoid future breakage. Even fine mechanical cracks can propagate quickly during rolling and cause shell spalling, so conservative assessment criteria are applied.

In summary, while HSS rolls show very good resistance to fine thermal checking, they are relatively sensitive to impact-induced mechanical cracks. Systematic NDT procedures are therefore a critical part of safe and reliable rolling mill roll management.

PC/FC Shape Control Optimization with HSS Rolls

HSS rolls differ from high-chromium or ICDP rolls not only in hardness and wear behavior, but also in thermal expansion coefficient, elastic modulus, friction coefficient, and surface hardness. These differences affect the loaded roll contour and thermal crown during rolling, which in turn influence strip flatness and crown.

To maintain stable strip shape when converting a stand (for example, F1–F2) from high-Cr to HSS work rolls, the following procedure is commonly used:

- Thermal profile measurement: After an HSS roll campaign, cooling water is stopped and the roll is left idle in air. After approximately 20 minutes, temperatures are measured along several axial locations to obtain the residual thermal profile.

- Wear contour measurement: After the roll cools to room temperature, the barrel profile is carefully measured. This provides the actual wear curve after a defined tonnage rolled.

- Model correction: The measured thermal and wear data are fed back to the mill’s PC (work roll bending) and FC (roll shifting and contour) models. Thermal crown and wear coefficients are updated accordingly.

- Shape control tuning: Based on the updated models, work roll bending forces, shifting strategies, and target roll profiles are adjusted to optimize strip crown and flatness.

With accurate thermal–mechanical modeling, HSS rolls can actually simplify shape control, because their slower wear and more stable surface conditions reduce profile drift between campaigns. This is particularly beneficial for high-strength and ultra-high-strength steel grades that demand narrow flatness tolerances.

Practical Recommendations for Applying HSS Rolls in Hot Strip Mills

For mills planning to introduce or further optimize high-speed steel hot rolling mill rolls, several practical guidelines can improve the success rate and economic benefit:

- Start in early finishing stands: Install HSS work rolls initially in F1–F2 (or F3) where the benefits of wear resistance and bite are greatest, while the impact on final surface quality is moderate and can be easily evaluated.

- Coordinate with backup rolls: Select compatible backup roll materials (for example, forged steel or bainitic ductile cast iron) and ensure that backup roll hardness and crown are matched to HSS work roll properties.

- Adapt cooling and lubrication: Fine-tune water flow, header positions, and oil lubrication rates to balance thermal conditions, friction, and bite. Avoid extreme quenching that could increase thermal shock.

- Upgrade roll shop capability: Ensure that grinding machines, grinding wheels, and measurement systems are suitable for HSS rolls and that grinding staff are trained in HSS-specific parameters.

- Implement strict NDT routines: After any incident or campaign, apply visual plus eddy current and ultrasonic testing to detect early defects, and establish clear criteria for maximum allowable crack depth and residual shell thickness.

- Record and analyze performance data: Track wear rate (t/mm), regrinding depth, roll campaigns, surface defect rates, and energy consumption before and after HSS introduction. Use data to refine roll grades and operational practices.

When these aspects are considered as a system—roll material selection, lubrication, cooling, grinding, inspection, and shape control—HSS rolls can significantly improve both production stability and economic performance in hot-rolled strip mills.

Summary and Outlook

The application of high-speed steel rolls in hot-rolled strip production represents a mature yet still evolving technology. By combining optimized HSS roll grades, advanced grinding strategies, effective lubrication systems, and rigorous inspection routines, steel producers can:

- Increase tonnage per roll and per millimeter of wear by more than an order of magnitude compared with high-chromium cast iron rolls.

- Reduce roll consumption, grinding cost, and unplanned downtime.

- Improve strip surface quality, flatness, and product consistency, especially for advanced and high-strength steels.

- Lower specific energy consumption through optimized friction and reduced rolling force.

Future developments will likely focus on further improving HSS shell toughness, developing hybrid HSS–tungsten carbide composite rolls for selected applications, and integrating more accurate online monitoring into roll management systems. Continuous experience feedback and data-driven optimization will remain essential to fully unlock the potential of high-speed steel rolls in hot strip rolling mills.