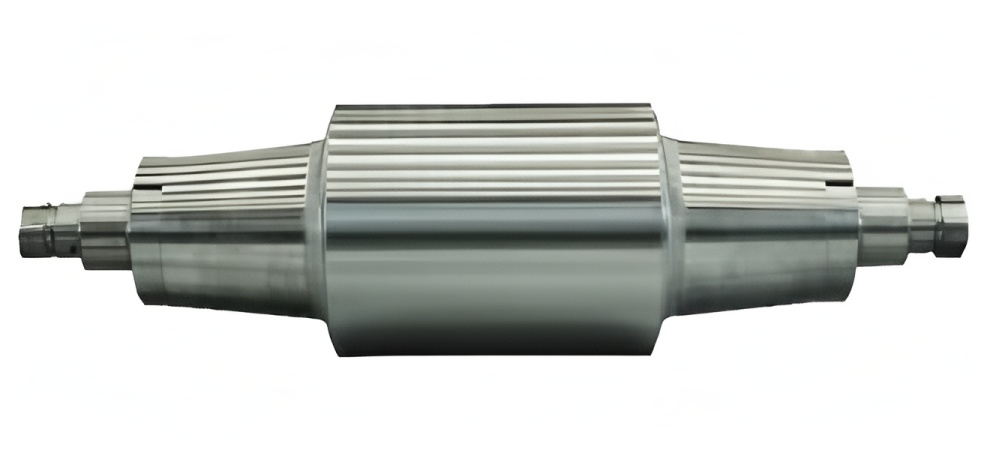

Rolls are the primary working components and tools in a rolling mill that enable the continuous plastic deformation of metals. A roll consists of three main parts: the roll body, the roll neck, and the shaft head. The roll body is the central section that directly contacts and deforms the metal, featuring a smooth cylindrical or grooved surface. The roll neck is mounted in bearings, transmitting rolling force to the mill housing via the bearing housing and press-down system. The drive-end shaft head connects to the gear unit through a coupling, transferring the motor’s torque to the roll. Rolls can be arranged in various configurations within the mill stand, such as two-high, three-high, four-high, or multi-high setups.

Following World War II, rolls began incorporating significant alloying elements. This development was driven by the growth of larger, continuous, high-speed, and automated steel rolling equipment, alongside increased strength and deformation resistance of rolled materials, which demanded enhanced roll performance. During this era, semi-steel rolls and nodular cast iron rolls emerged. After the 1960s, powder metallurgy tungsten carbide rolls were successfully developed. In the early 1970s, centrifugal casting technology and differential temperature heat treatment, widely adopted in Japan and Europe, substantially improved the overall performance of strip mill rolls. Composite high-chromium cast iron rolls were also successfully implemented in hot strip mills. Concurrently, Japan applied forged white iron and semi-steel rolls. The 1980s saw Europe introduce high-chromium steel rolls, cold rolls with ultra-deep hardening layers, and special alloy cast iron rolls for finishing small sections and wire rods. The evolution of modern steel rolling technology continues to drive the development of even higher-performance rolls. Rolls produced via centrifugal casting and novel composite methods—such as the continuous pouring process for cladding (CPC), the Osprey spray deposition method, electroslag welding, and hot isostatic pressing—are now used in Europe and Japan. These comprise composite rolls with a high-speed steel outer layer over a high-strength, tough core of forged steel or nodular graphite cast iron, as well as cermet rolls, applied in new-generation profile, wire, and strip mills.

Roll varieties and manufacturing processes have continuously evolved alongside metallurgical advancements and rolling equipment improvements. In the Middle Ages, low-strength gray cast iron rolls were used for rolling soft non-ferrous metals. By the mid-18th century, Britain had mastered the production of chilled cast iron rolls for steel plate rolling. The progress in European steelmaking during the latter half of the 19th century required rolling heavier ingots, exceeding the strength capabilities of gray or chilled cast iron rolls. This led to the development of ordinary cast steel rolls with 0.4%–0.6% carbon content. The advent of heavy forging equipment further enhanced the strength and toughness of forged rolls of similar composition. The early 20th century introduced alloying elements and heat treatment, significantly improving the wear resistance and toughness of both cast and forged steel rolls for hot and cold rolling. Adding molybdenum to cast iron rolls for hot strip improved the surface quality of the rolled product, and composite casting via the冲洗法 (flush casting) method substantially increased the core strength of cast rolls.

China began mass-producing cast rolls in the 1930s, though varieties were limited. Its first specialized roll plant was established in Xingtai, Hebei, in the late 1950s. In 1958, Anshan Iron and Steel Company trial-produced and used the first 1050mm large nodular cast iron roll for a blooming mill. The 1960s saw the successful manufacture of cold rolling work rolls and large forged steel rolls. In the late 1970s, Taiyuan Iron and Steel Company and the Beijing Iron and Steel Research Institute jointly trial-produced centrifugally cast cast iron rolls for steckel mills and hot strip continuous mills. Xingtai Metallurgical Machinery & Roll Co., Ltd. successfully trial-produced semi-steel work rolls for hot strip mills and work rolls for cold wide strip mills. During the 1980s, China developed new roll varieties including large forged steel backup rolls, forged semi-steel rolls, forged white cast iron rolls, powder metallurgy tungsten carbide roll rings, and high-chromium cast iron rolls. By the 1990s, China’s roll production largely met domestic demand and began partial exports, though further variety expansion and quality improvement remained necessary.

Roll Classification

Rolls can be classified by several methods, primarily:

By product type: Strip mill rolls, section mill rolls, wire rod mill rolls, etc.

By position in the mill train: Blooming mill rolls, roughing rolls, finishing rolls, etc.

By function: Scale breaker rolls, piercing rolls, leveling rolls, etc.

By material: Steel rolls, cast iron rolls, cemented carbide rolls, ceramic rolls, etc.

By manufacturing method: Cast rolls, forged rolls, surfacing rolls, sleeve rolls, etc.

By rolling state: Hot rolls, cold rolls.

These classifications can be combined to define rolls more specifically, such as a centrifugally cast high-chromium cast iron work roll for hot-rolled strip.