Causes and Solutions for Steel Piling in High-Speed Wire Rod Rolling

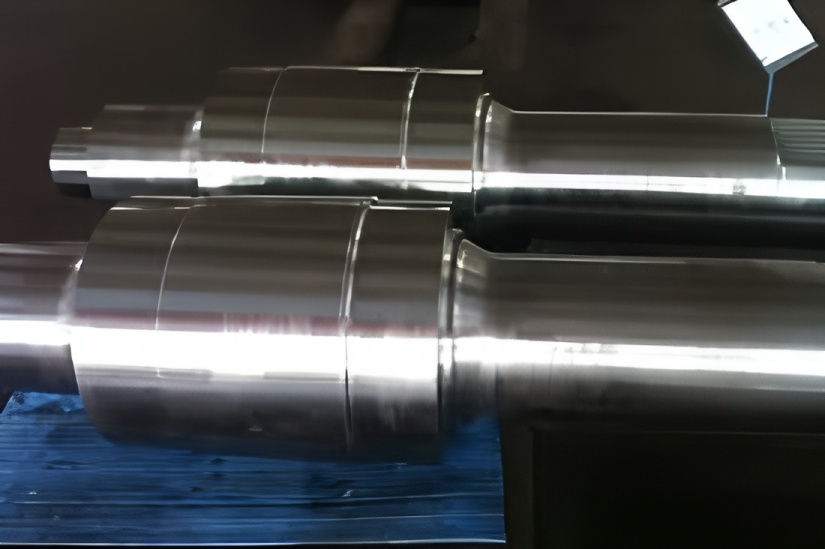

The production line equipment at Shougang Group’s No. 1 Wire Rod Plant is based on a fifth-generation Morgan mill design and manufactured domestically. With a maximum stable rolling speed of 88 m/s, the line comprises 28 stands: 14 roughing and intermediate mills, 4 pre-finishing mills (alternately horizontal and vertical), and 10 top-45° finishing mills, plus a laying head. Producing wire rods from φ5.5 mm to φ16 mm, the line handles a wide size range and product variety. Notably, the steel piling accident rate for small sizes (≤φ6.5 mm) is significantly higher due to their higher speeds and smaller sections. This article analyzes causes and solutions by rolling area.

1. Roughing and Intermediate Rolling Area (Stands 1-14)

1.1 Piling due to Failure to Enter Next Pass

Causes:

Skewed head from previous pass; raised exit guide from tail whip; incorrect inlet guide gap; misaligned guide/pass; groove slip; non-compliant section size; split ends from billet.

Solutions:Check roll diameter/wear, drive part gaps, guide consistency; adjust inlet guide gap/distance; adjust roll gap or regroove for new grooves; inspect billets and increase 1# shear cut length.

1.2 Interstand Piling After Biting

Causes:

Incorrect speed/roll diameter settings; improper tension adjustment after roll/groove change; large billet temperature fluctuation; sudden speed changes from electrical issues; incorrect speed adjustments by operator.

Solutions:Correct speed/diameter settings and tension relationships; coordinate heating furnace adjustments; inspect electrical cabinets.

1.3 Tail Piling

Causes:

Upstream tension causes tail to pile at downstream stand when released.

Solutions:Adjust tension and roll gap settings.

2. Pre-Finishing Area (Stands 15-18)

2.1 Interstand Piling

Causes:

Incorrect roll gap/diameter/speed settings; improper guide installation; guide striking; tension issues from prior area; electrical speed abnormalities.

Solutions:Recheck parameters; inspect/replace guides; adjust loopers and inspect regularly; adjust tension; electrical inspection.

2.2 Stand Jump/Trip

Causes:

Cooling water/lubrication failure; motor trip; accident detection activation.

Solutions:Check water pressure/valves; inspect motor/lubrication; secure looper pendants and check sensors.

3. High-Speed Area (Finishing Mill to Laying Head)

3.1 Interstand Piling in Finishing Mill

Causes:

Seized guide wheels/burned bearings; split piece; misaligned guides/rolls; incorrect gap/incoming size; broken roll rings; broken looper wire triggering stop.

Solutions:Replace guides/wheels; enhance billet inspection and head cutting; readjust gaps; replace rolls; check sensors and clear obstructions.

3.2 Piling at Finishing Mill Sample Box

Causes:

Improper water cooling valve operation; foreign objects in cooling line; misaligned cooling guides; excessive water pressure/flow; speed mismatch between mill, pinch rolls, and laying head.

Solutions:Inspect water valve control; verify guide/nozzle alignment; clear obstructions; adjust speed coordination; enlarge guide/nozzle sizes if needed.

3.3 Piling at Pinch Roll/Laying Head

Causes:

Worn/misaligned conduits; faulty detection signals; worn laying pipe; short tail clip delay; speed mismatch; material defects (folds, ears).

Solutions:Replace conduits; check sensors; replace laying pipe; extend clip delay; adjust speeds; monitor billet quality.

4. Piling at Flying Shear

Causes:

Speed mismatch with upstream mill; improper head/tail cutting; worn blades/switches; control failure.

Solutions:Reset shear lead factor; adjust cut length; inspect blades/guides; check sensors.

5. Piling at Looper

Causes:

Incorrect delay/height settings; worn rollers/guides; scanner failure; blocked detection signal; water mist/light interference.

Solutions:Adjust parameters; replace parts; recalibrate scanner; install shields/blowers.

Conclusion

Quick, accurate diagnosis is essential when piling occurs. Comprehensive analysis of multiple factors can reduce downtime and prevent recurrences. Regular checks of section sizes, tension relationships, and guide conditions are crucial for minimizing accidents.