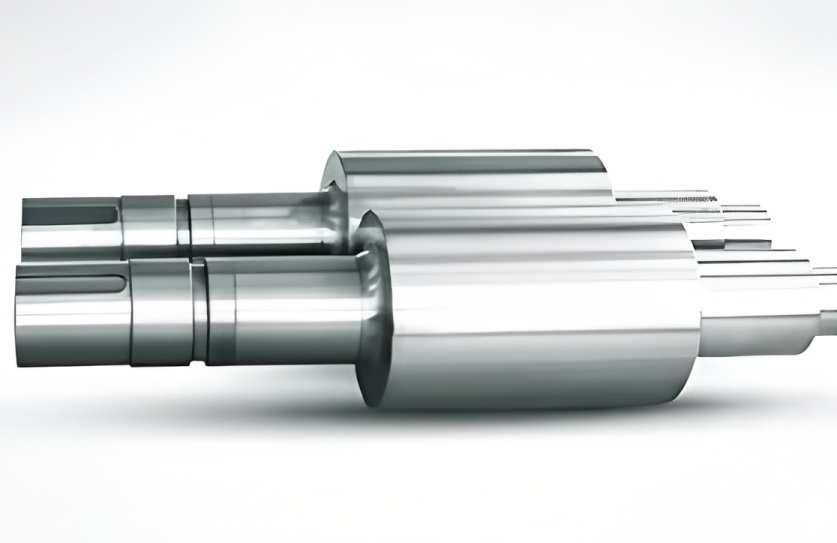

The term “high-speed steel rolls” currently refers to high-carbon high-speed steel composite rolls. The working layer is made of high-carbon high-speed steel, while the core is made of nodular cast iron, graphite steel, or forged steel. These are produced via centrifugal casting or the CPC (Continuous Pouring Process for Cladding) method. This composition is fundamentally different from traditional tungsten-molybdenum high-speed steels like M2 and M4. Under normal rolling conditions, the service life of high-speed steel rolls is more than three times that of alloy cast iron rolls.

Keywords: High-speed steel roll

Characteristics of High-Speed Steel Rolls

High-speed steel rolls contain high carbon and high alloying elements such as vanadium, chromium, tungsten, molybdenum, and niobium. As a result, the carbides in the roll structure are primarily MC and M₂C types, which are highly hard and wear-resistant.

These rolls exhibit excellent thermal stability, maintaining high surface hardness and wear resistance even at rolling temperatures.

They possess strong hardenability, with minimal hardness decrease from the surface to the interior of the working layer, ensuring consistent wear resistance throughout.

Under proper cooling conditions, a thin, dense oxide film forms on the roll surface. This film remains stable and adherent for extended periods, significantly enhancing wear resistance.

The oxide film reduces friction between the roll and the material, which can lead to slipping during rolling and complicate mill adjustment.

High-speed steel has a high thermal expansion coefficient and good thermal conductivity. This can cause changes in roll shape during rolling, affecting product dimensional accuracy. Therefore, using these rolls in strip and plate mills may require modifications to both the cooling system and roll profile design.

The use of alloy nodular iron, graphite steel, or forged steel for the core provides high strength in the roll neck.

Although high-speed steel offers excellent wear resistance, it has relatively poor accident resistance. Thus, performance depends not only on roll quality but also heavily on usage conditions and maintenance.

Machining of High-Speed Steel Rolls

Increased hardness makes these rolls more challenging to machine. Processing passes for high-speed steel rolls used in wire and bar mills—especially threading grooves during reuse—involve intermittent cutting, increasing difficulty. Selecting suitable tools and cutting parameters is essential for successful application in bar mills.

For cutting tools, imported cubic boron nitride (CBN) or carbide inserts (e.g., Swedish Sandvik HIP grade K01 series) are preferred. Domestic alternatives include carbide tools like YD500, YD05, or YG6A. Carbide tools are required for turning rebar rolls.

Recommended cutting parameters:

For external cylindrical turning: speed ≈ 10 m/min, depth of cut 1–3 mm, feed rate 0.2–0.5 mm/rev.

For hole machining or threading grooves: speed ≈ 5 m/min, depth of cut 0.1–0.2 mm.

For milling rebar ribs, use a fly cutter milling machine with carbide milling cutters such as YD500, YD05, or YTI.

Overall, machining high-speed steel rolls—whether turning passes or milling grooves—is considerably more difficult and time-consuming (3–4 times longer) compared to alloy cast iron rolls.

Cooling Conditions and Requirements for High-Speed Steel Rolls in Wire and Bar Mills

Roll cooling serves three main purposes during rolling:

Prevent overheating and subsequent spalling.

Avoid excessive surface temperatures that could alter the microstructure, reducing wear resistance and affecting surface quality.

Delay the formation and propagation of thermal fatigue cracks.

Heat primarily comes from contact with the rolled material, though material deformation also contributes. The contact temperature is roughly the average between the material and roll temperatures, with surface temperatures reaching about 500°C. The adoption of endless rolling technology places even greater demands on roll cooling.

An ideal cooling system uses annularly arranged nozzles to ensure continuous, adequate water flow into the roll grooves. The nozzle near the exit guide should deliver about 30% of the total water volume at a 20–30° angle to rapidly cool the groove area just after material exit. Water pressure should be ≥0.5 MPa, with a minimum flow of 300 L/min per groove. 70–80% of water should be supplied at the outlet side, ensuring full coverage in the groove. The lower roll typically requires more water than the upper due to poorer cooling conditions. Cooling water should be filtered to minimize solid particle content.

While cooling systems vary across mills, effective cooling—achieving lower and uniform roll temperatures—is critical for extending service life and improving product surface quality. Increasing water flow (when pressure and method are fixed) significantly reduces roll temperature and thermal cracking.

Handling of Rolling Accidents with High-Speed Steel Rolls

Abnormal usage accounts for about 30% of total roll consumption in metallurgical applications. Strengthening operational management, adhering to rolling processes, ensuring mill reliability, and minimizing accidents are essential to reducing roll consumption.

In case of cobbles or pile-ups during rolling with high-speed steel rolls:

Immediately stop water cooling.

Quickly raise the top roll to separate from the material.

Remove accumulated material from the bottom roll promptly.

Allow the heated groove to cool slowly in air.

After resolving the incident, change the groove position by 2–3 grooves upon restart. Do not direct cooling water onto the overheated groove. If changing grooves is not possible, replace the roll and allow it to cool naturally before reuse. Direct water contact on an overheated groove will cause cracking.