Classification of Mill Rolls

There are various types of rolls used in industrial applications. The most common include cast steel rolls, cast iron rolls, and forged rolls. A limited number of carbide rolls are also utilized in profile rolling mills.

Classification by Forming Method:

Casting Rolls: Manufactured by directly casting molten steel or iron. These are further categorized by material into cast steel rolls and cast iron rolls, and by production method into solid cast rolls and composite cast rolls.

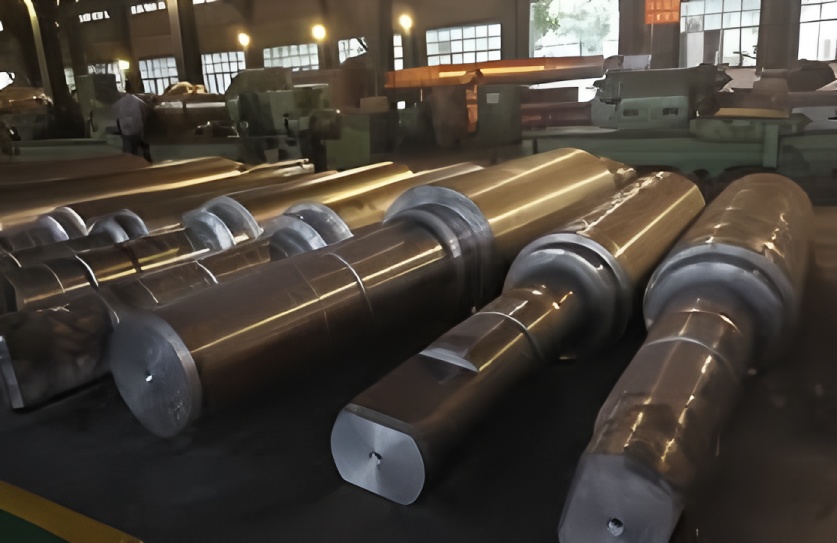

Forging Rolls: Classified by material into:

(1) Forged alloy steel rolls

(2) Forged semi-steel rolls

(3) Forged semi-high-speed steel rolls

(4) Forged white cast iron rolls

Classification by Process Method:

Solid Rolls: Produced from a single material through casting or forging. Variations in structure and properties between the roll body and neck are controlled via manufacturing and heat treatment processes. Both forged and statically cast rolls fall into this category.

Metallurgical Composite Rolls: Mainly include semi-flush composite casting, overflow (full-flush) composite casting, and centrifugal composite casting. Other specialized methods include continuous casting for cladding (CPC), spray deposition, hot isostatic pressing (HIP), and electroslag welding.

Assembled Rolls: Consist primarily of sleeve-and-core combined roll systems.

Classification by Material:

Cast steel series rolls

Cast iron series rolls

Forged series rolls

Common Heat Treatment Methods for Rolls:

Stress relief annealing, isothermal spheroidizing annealing, diffusion annealing, normalizing, tempering, quenching, and cryogenic treatment.