Cold rolling mill rolls are critical components in the metal forming industry, especially for producing high-precision flat products such as cold-rolled steel strips and foils. These rolls for cold rolling mill systems must endure extreme mechanical stress, thermal cycling, and abrasive wear while maintaining dimensional accuracy and surface finish. This comprehensive guide explores the composition, manufacturing processes, material properties, and maintenance practices of cold rolling mill rolls, providing valuable insights for engineers, mill operators, and procurement specialists.

Understanding Cold Rolling Mill Rolls: Function and Classification

In a typical four-high or six-high cold rolling mill setup, two types of rolls play distinct roles: work rolls and backup rolls. The work roll directly contacts the metal strip, transmitting force and shaping the material through plastic deformation. Backup rolls support the work rolls to prevent deflection under high rolling loads. While both are essential, when people refer to “cold mill rolls“, they usually mean the work rolls due to their direct interaction with the product and higher performance demands.

The primary requirements for cold rolling mill rolls include:

- High surface hardness (typically 90–100 HS Shore)

- Uniform microstructure and carbide distribution

- Excellent wear resistance and fatigue strength

- Precise dimensional control and concentricity

- Sufficient core toughness to resist spalling and cracking

Chemical Composition of Cold Rolling Mill Roll Materials

The performance of rolling mill roll material is largely determined by its chemical composition. Forged steel work rolls used in cold rolling are typically made from high-carbon, high-chromium alloy steels. These materials offer an optimal balance between hardness, toughness, and hardenability.

The standard chemical composition range for forged cold rolling mill rolls is shown below:

| Element | Symbol | Typical Range (%) | Primary Function |

|---|---|---|---|

| Carbon | C | 0.7 – 1.0 | Forms carbides; increases hardness and wear resistance |

| Chromium | Cr | 1.5 – 5.5 | Enhances hardenability; forms (Fe,Cr)₃C and (Fe,Cr)₇C₃ carbides |

| Molybdenum | Mo | 0.2 – 0.6 | Improves tempering stability and high-temperature strength |

| Vanadium | V | 0.1 – 0.2 | Refines grain size; promotes fine, dispersed carbides |

| Silicon | Si | 0.25 – 0.5 | Deoxidizer; improves strength but not a primary alloying element |

| Manganese | Mn | 0.25 – 0.5 | Aids deoxidation and desulfurization; enhances hardenability slightly |

Higher chromium content (above 3%) enables deeper hardening—up to 25 mm compared to 15 mm with conventional Cr levels—making semi-high-speed steel (SHSS) and high-speed steel (HSS) rolls increasingly popular in modern cold mills. Molybdenum contributes to secondary hardening during tempering, which helps maintain hardness at elevated operating temperatures.

Role of Carbon and Carbide Morphology

Carbon exists in two forms within the roll matrix: dissolved in martensite and retained austenite, and precipitated as undissolved carbides. The most common carbides are (Fe,Cr)₃C and, at higher Cr levels, (Fe,Cr)₇C₃. These particles are typically 1–3 μm in size and constitute about 5–10% of the microstructure by volume.

While increased carbon improves wear resistance, it also raises brittleness and can lead to carbide banding or network formation, especially in large ingots. Mills prone to accidents (e.g., threading issues, misruns) should use lower-carbon grades to enhance fracture resistance. Conversely, stable production lines can utilize higher-carbon rolls for extended service life.

Microstructure and Hardness Characteristics

The ideal metallographic structure of a cold rolling mill roll consists of:

- Fine, uniformly dispersed undissolved carbides

- A martensitic matrix (cryptocrystalline or fine-needle type under optical microscope)

- 5–10% retained austenite

During quenching, rapid cooling suppresses diffusion, leading to a non-equilibrium transformation into martensite. Due to low tempering temperatures (typically 150–200°C), no visible tempering of martensite occurs under optical microscopy. Electron microscopy reveals predominantly twinned martensite, with lath martensite appearing only under specific conditions like high Cr content or lower quenching temperatures.

Hardness Requirements Across Applications

Roll hardness is measured using Shore scleroscopes (HS) or Rockwell C (HRC) scales depending on application:

| Roll Type | Application | Hardness (HS) | Hardness (HRC) |

|---|---|---|---|

| Work Roll – Strip Mill | Cold rolling of steel strips | 90 – 95 HS | ~60 HRC |

| Flat Roll | Sheet leveling and finishing | 95 – 100 HS | ~63 HRC |

| Foil Roll | Ultra-thin foil production | – | 61 – 64 HRC |

| Roll Neck | Bearing support area | 30 – 50 HS | ~40 HRC |

| Hardened Neck (Modern Design) | Advanced bearing systems | < 80 HS | ~55 HRC |

Surface residual compressive stress significantly influences measured hardness—higher stress leads to higher readings. Therefore, mills under light load may use higher-hardness rolls, whereas those with frequent operational disruptions benefit from slightly softer rolls to reduce spalling risk.

Manufacturing Process of Cold Rolling Mill Rolls

The production of high-quality forged steel rolls involves several tightly controlled stages: smelting, forging, heat treatment, machining, and inspection. Each step is crucial to achieving the desired metallurgical and mechanical properties.

1. Smelting: Ensuring Steel Cleanliness

High-purity molten steel is essential to minimize inclusions that could initiate cracks. Common smelting routes include:

- Alkaline electric arc furnace (EAF) + ladle refining

- Acid open-hearth process (less common today)

- Vacuum degassing (VD) or vacuum oxygen decarburization (VOD)

- Electroslag remelting (ESR) for premium-grade rolls

Secondary refining techniques help achieve sulfur levels below 0.010%, oxygen content under 15 ppm, and inclusion ratings per ASTM E45 standards. Ingots are cast polygonal with a “big-end-up” orientation to promote directional solidification and reduce central segregation.

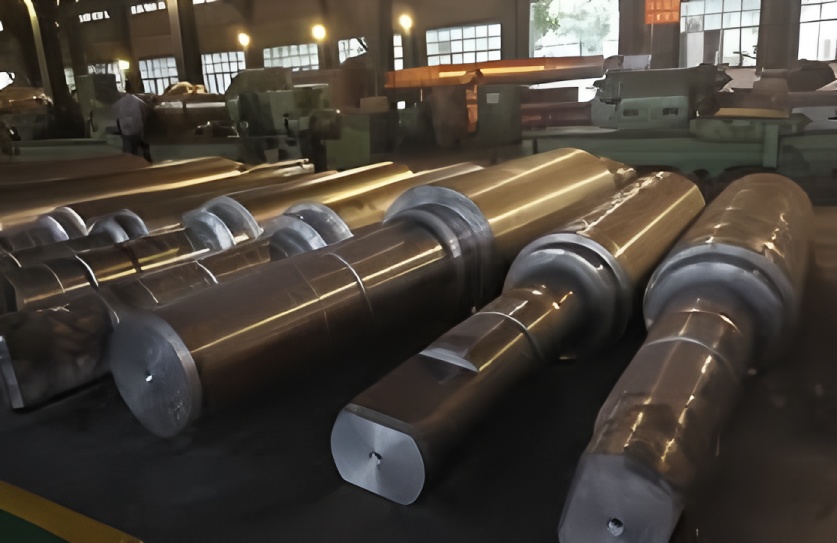

2. Forging: Refining the As-Cast Structure

After demolding, hot ingots are transferred directly to hydraulic presses for free forging. The objectives are to:

- Break down coarse dendritic and carbide networks

- Close internal porosity and shrinkage cavities

- Improve homogeneity and density

- Align grain flow along the roll axis

Key parameters include:

- Forging ratio: Minimum 3:1 (preferably 4:1)

- Temperature control: Start at 1150–1200°C; finish above 850°C

- Anvil design: V-shaped anvils promote axial metal flow

One-ingot-per-roll practice is recommended for critical applications to ensure traceability and structural integrity. Very small rolls (<200 mm diameter) may be machined directly from forged bars or slabs.

3. Heat Treatment: Achieving Target Properties

Heat treatment is the most critical phase in determining final roll performance.

Pre-Quenching Treatments

- Normalizing: Breaks up carbide networks; typically done at 900–950°C

- Spheroidizing annealing: Converts lamellar pearlite to globular form for better machinability and quench response

- Stress-relief annealing: Allows hydrogen diffusion to prevent flaking

Final Quenching and Tempering

Modern cold rolls undergo selective quenching of the roll body using:

- Medium-frequency induction heating (most common)

- Dual-frequency or mobile coil systems for uniform depth

- Flame heating (limited use)

The roll body is heated rapidly to 850–900°C and then quenched with high-pressure water jets. Core cooling is accelerated by circulating water through center holes if present. Low-temperature tempering follows immediately at 150–200°C to stabilize the structure.

For rolls requiring minimal retained austenite (<5%), sub-zero treatment (-50°C to -80°C) is applied before tempering.

4. Machining and Surface Finishing

Precision machining ensures geometric accuracy and prepares the roll for service:

- Rough machining after annealing removes scale and corrects shape

- Center hole drilling (if required) with fine surface finish (Ra ≤ 1.6 μm) to avoid fatigue initiation

- Final grinding post-quenching using CNC-controlled roll grinders

- Surface roughness tailored to application: smooth (Ra 0.2–0.4 μm) or textured

Due to high residual stresses, grinding parameters (wheel type, feed rate, coolant flow) must be optimized to prevent thermal cracking. Diamond or CBN wheels are often used for high-hardness rolls.

5. Inspection and Quality Assurance

All cold rolling mill rolls undergo rigorous testing:

| Test Method | Purpose | Standard / Acceptance Criteria |

|---|---|---|

| Ultrasonic Testing (UT) | Internal flaw detection | ASTM A388; defect size based on fracture mechanics |

| Shore Hardness Mapping | Surface hardness uniformity | ±3 HS across face; min 3-point average per zone |

| Metallography | Carbide dispersion, grain size | ASTM E3, E45; no continuous carbide networks |

| Dimensional Check | Concentricity, taper, crown | Tolerance ±0.01 mm/m |

| Eddy Current Testing | Surface crack detection (post-service) | Depth sensitivity down to 0.1 mm |

Residual Stress and Its Impact on Performance

Residual stress develops during quenching due to uneven thermal contraction and phase transformation. The outer layer experiences compressive stress (beneficial for wear and contact fatigue), while the core is under tensile stress (increasing fracture risk).

This stress state affects:

- Effective hardness and wear resistance

- Spalling and thermal crack initiation

- Roll bending behavior under load

- Post-peening surface texture stability

Surface residual stress can be measured non-destructively via X-ray diffraction. Depth profiling requires destructive methods involving strain gauges during incremental material removal.

Maintenance and Reconditioning of Cold Rolls

Proper maintenance extends roll life and ensures consistent product quality.

Intermediate Grinding

Performed between campaigns to remove surface microcracks and oxide buildup. Modern grinding machines integrate eddy current sensors to detect subsurface flaws in real time, allowing precise control of grind depth and preventing over-grinding.

Surface Roughening Techniques

Some applications require controlled surface texture for improved coating adhesion or drawing performance:

- Shot blasting: Traditional method; roughness depends on shot size, velocity, and exposure time

- Electric pulse texturing (EPT): High-precision, repeatable patterns

- Laser texturing: Offers digital control over dimple geometry and distribution

Re-Quenching Capability

When the hardened layer is worn but sufficient diameter remains, re-quenching can restore surface properties. However, repeated heat treatments degrade core toughness. Best practice includes:

- Full tempering before re-austenitizing to relieve stress

- Reduced heating rates to minimize new quenching stresses

- Limited to one re-quench cycle for critical applications

Alternative Types of Cold Rolling Mill Rolls

Beyond traditional forged steel, other roll types serve niche applications:

Centrifugally Cast Rolls

Made from high-chromium cast iron or cast steel, these rolls offer excellent wear resistance and do not require re-quenching. Suitable for stable operations with low accident rates. Used in some cold strip mills and skin-pass lines.

Tungsten Carbide Composite Rolls

Tungsten carbide rolls for rolling mills are used in wire flattening, foil rolling, and spring steel production. With hardness exceeding 90 HRC, they provide exceptional dimensional stability and surface finish. Typically constructed as composite rings shrunk onto steel shafts.

Sendzimir Mill Rolls

In 20-high cluster mills (Sendzimir), work rolls are made from high-carbon, high-chromium tool steels or high-speed steels. Intermediate rolls use medium-alloy cold-work die steels. These small-diameter rolls demand ultra-high hardness and precision.

Leading Mill Roll Manufacturers and Industry Trends

Global rolling mill roll manufacturers such as Hanmill Rolls, Daido, Mitsubishi Hi-Metals, and SMS Group continue to innovate in material science and processing. In India, companies like rolling mill.roll.manufacturers.in.india are expanding capabilities in forged and centrifugal rolls.

Current trends include:

- Adoption of semi-high-speed steel (SHSS) rolls for deeper hardening

- Integration of IoT sensors for predictive maintenance

- Use of AI-based grinding optimization systems

- Growing demand for sustainable manufacturing with reduced scrap and energy use

Whether you’re sourcing steel rolling mill rolls manufacturers, evaluating mill roll equipment, or optimizing your roll shop steel mill operations, understanding the science behind cold rolling mill rolls is key to improving productivity, reducing downtime, and enhancing product quality.