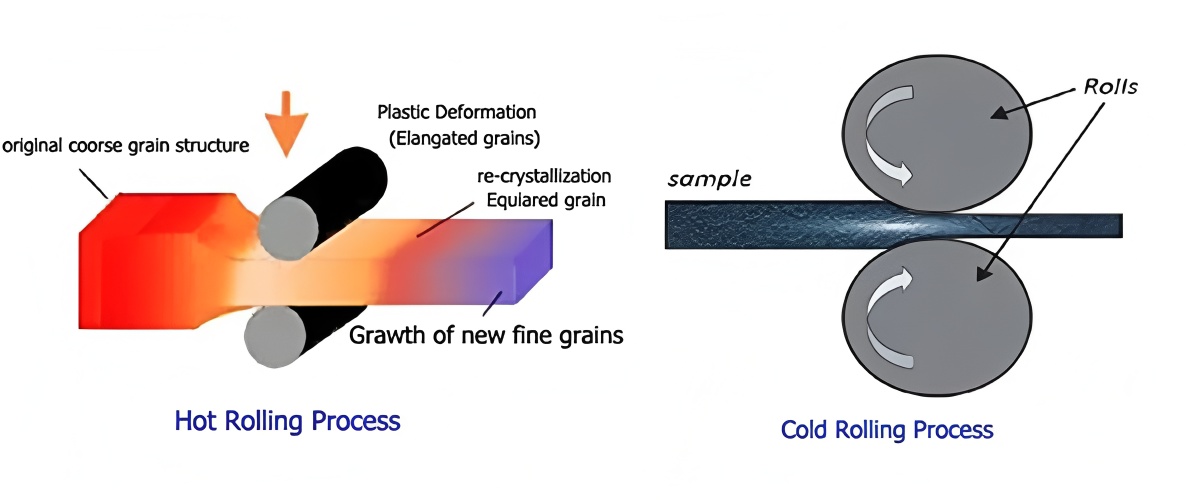

Cold rolling work rolls are among the most critical components in modern flat-rolled steel production. Their performance directly influences product surface quality, dimensional accuracy, mill efficiency, and operational costs. As cold rolling processes operate without the benefit of elevated temperatures to soften the metal—unlike hot rolling—the mechanical demands on work rolls are significantly higher. This comprehensive guide explores the key performance characteristics, material evolution, heat treatment protocols, and selection criteria for cold rolling mill rolls used in today’s high-speed, high-precision tandem mills.

What Is a Cold Rolling Work Roll?

In a cold rolling mill—typically configured as a 2-high, 4-high, or 6-high tandem mill—the work roll is the smallest-diameter roll that makes direct contact with the steel strip. It transmits enormous pressure (often exceeding 10,000 MPa at bite) and shear forces to reduce thickness while maintaining tight tolerances and superior surface finish. Unlike backup rolls that provide structural support, work rolls endure the brunt of wear, thermal cycling, and mechanical fatigue.

Due to the absence of scale and the high deformation resistance of cold steel, work rolls must exhibit exceptional hardness, wear resistance, crack resistance, and dimensional stability. Any surface defect—such as spalling, thermal cracking, or uneven roughness—can transfer directly onto the steel strip, causing costly rejects or mill downtime.

Key Performance Characteristics of Cold Rolling Work Rolls

Modern cold rolling operations demand work rolls that meet stringent performance benchmarks. Below are the five core attributes that define roll quality and longevity:

| Performance Parameter | Typical Requirement | Impact on Mill Operation |

|---|---|---|

| Surface Hardness | 90–105 HSD (Shore D) or 62–68 HRC | Determines wear resistance and surface finish retention |

| Hardened Layer Depth | 15–50+ mm (depending on material) | Extends service life between regrinds; reduces re-heat-treatment frequency |

| Tensile Strength (σb) | ≥ 2,000 MPa | Prevents roll breakage under high rolling loads |

| Thermal Crack Resistance | High fracture toughness (KIC > 30 MPa·m1/2) | Mitigates spalling during cobbles, strip breaks, or speed changes |

| Surface Roughness Retention | Ra = 0.2–0.8 μm over 500–2,000 km rolled | Critical for automotive, appliance, and coated steel applications |

1. Work Roll Strength

Cold deformation resistance is 5–10× higher than in hot rolling. At initial bite, localized contact pressures can exceed 10 GPa. To withstand this, cold work rolls require ultra-high tensile strength (≥2,000 MPa) and a homogeneous microstructure free of inclusions or segregation.

Advanced metallurgical practices—such as vacuum induction melting (VIM), electroslag remelting (ESR), and controlled forging—are now standard for premium rolls. Alloying elements like molybdenum (Mo: 0.5–2.0%) and vanadium (V: 0.1–0.5%) form fine carbides that inhibit dislocation motion, enhancing both strength and temper resistance.

2. Wear Resistance

Wear in cold rolling manifests as radial loss (macro-wear) and surface smoothing (micro-wear). Abrasive particles from oxide debris, lubricant contaminants, or work-hardened strip edges accelerate degradation. High-chromium and high-speed steel rolls combat this through hard, stable carbides.

Proven strategies to improve wear life include:

- Increasing Cr content from 3% to 10–18% (doubles wear life)

- Using high-speed steel (HSS) with MC/M7C3 carbides (HV 2,500–3,000)

- Applying surface treatments like laser cladding or plasma nitriding

- Incorporating titanium (Ti) to form TiC nanoparticles that pin grain boundaries

3. Anti-Accident Performance

“Accidents” such as cobbles, overlapping strips, or sudden stops cause instantaneous frictional heating—up to 800–1000°C locally. This induces thermal shock, phase transformation, and microcracking. Rolls with poor thermal fatigue resistance suffer spalling within hours.

Forged semi-HSS and high-alloy Cr5 rolls offer superior accident tolerance due to their high fracture toughness and retained austenite, which absorbs stress via transformation toughening.

4. Hardened Layer Depth

A deeper hardened case allows more regrinds before re-quenching is needed. Traditional Cr3 rolls offer ~10 mm depth, but modern Cr5-Ni or HSS rolls achieve 30–50 mm using dual-frequency induction hardening or cryogenic treatment.

For example, increasing Cr from 2% to 5% and adding 1–2% Ni can extend case depth by 15–20 mm, effectively doubling roll life in high-utilization mills.

Material Selection Guide for Cold Rolling Work Rolls

Choosing the right roll material depends on product mix, mill configuration, rolling speed, and cost-per-ton targets. Below is a detailed comparison of mainstream cold work roll materials used globally:

| Material Type | Typical Composition (wt%) | Hardness (HSD) | Case Depth (mm) | Best For |

|---|---|---|---|---|

| High-Cr Cast Iron (Cr3) | C: 2.8–3.2, Cr: 2.5–3.5, Mo: 0.3–0.6 | 88–94 | 8–12 | Low-speed mills, mild steel, infrequent grade changes |

| Forged Cr5 Steel | C: 0.5–0.7, Cr: 4.5–5.5, Mo: 0.8–1.2, V: 0.1–0.2 | 92–98 | 15–25 | Medium-high speed mills, galvanized & automotive grades |

| Semi-High-Speed Steel (Semi-HSS) | C: 1.0–1.4, Cr: 5–6, Mo: 2–3, V: 1–2 | 95–102 | 20–35 | High-precision mills, stainless steel, frequent cobble risk |

| High-Speed Steel (HSS) | C: 1.8–2.2, Cr: 4–5, Mo: 4–5, V: 3–5, W: 3–6 | 98–105+ | 30–50+ | Ultra-high-speed tandem mills (e.g., Baosteel, Nippon Steel), premium coated steels |

Heat Treatment Protocols

All high-performance cold work rolls undergo precise heat treatment to develop the required surface hardness and core toughness. Two primary methods dominate:

- Induction Surface Hardening: Most common for forged rolls. Uses medium/high-frequency coils to rapidly heat the surface layer (5–50 mm), followed by water quenching. Allows deep case with minimal distortion.

- Overall Quenching + Tempering: Used for smaller rolls or cast materials. Entire roll is austenitized (~950–1050°C), oil/water quenched, then tempered at 500–580°C to relieve stress and stabilize microstructure.

Advanced techniques like cryogenic treatment (soaking at -196°C in liquid nitrogen) convert retained austenite to martensite, boosting hardness by 2–5 HSD and improving dimensional stability.

Future Trends in Cold Rolling Work Roll Technology

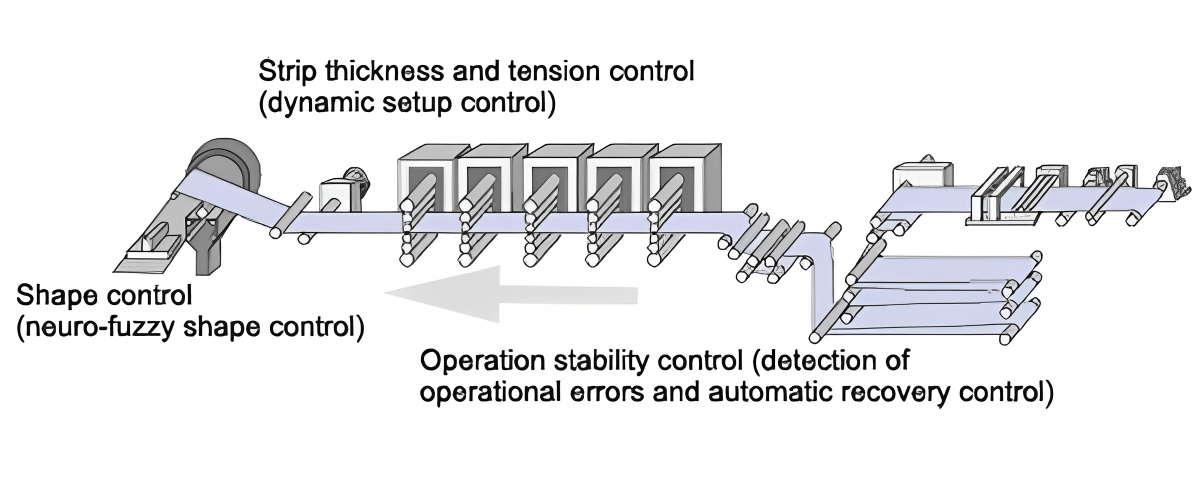

As cold rolling mills push toward speeds >2,000 m/min and tighter tolerances (±5 μm), roll technology continues to evolve:

- Nitrogen-alloyed rolls: N (0.05–0.15%) forms fine VN/TiN precipitates that refine grains and enhance strength without sacrificing toughness.

- Composite rolls: Centrifugally cast rolls with HSS outer layer and ductile iron core combine wear resistance with impact resilience.

- Digital twin monitoring: Embedded sensors track roll temperature, vibration, and wear in real time, enabling predictive maintenance.

- Sustainable reconditioning: Advanced grinding and re-hardening extend roll life beyond 10 cycles, reducing scrap and CO2 footprint.

Leading global producers—including Akers (Sweden), Nippon Steel (Japan), and United Rolls—now supply HSS and semi-HSS cold work rolls to major steelmakers in Asia, Europe, and North America. In China, Baosteel and Shougang have successfully implemented HSS rolls in their 4-high and tandem cold mills, reporting 30–50% reductions in roll consumption and improved surface quality for automotive-grade steel.

For mill operators and roll procurement specialists, selecting the optimal cold rolling work roll requires balancing upfront cost against total cost of ownership (TCO). While HSS rolls may cost 2–3× more than Cr5 rolls, their extended life, reduced changeovers, and superior product quality often justify the investment—especially in high-value product lines.

Whether you’re sourcing cold rolling mill rolls, evaluating work roll material options, or troubleshooting spalling in cold work rolls, understanding these performance drivers ensures smarter decisions and maximized mill productivity.