An In-Depth Guide to High-Speed Steel (HSS) Rolls

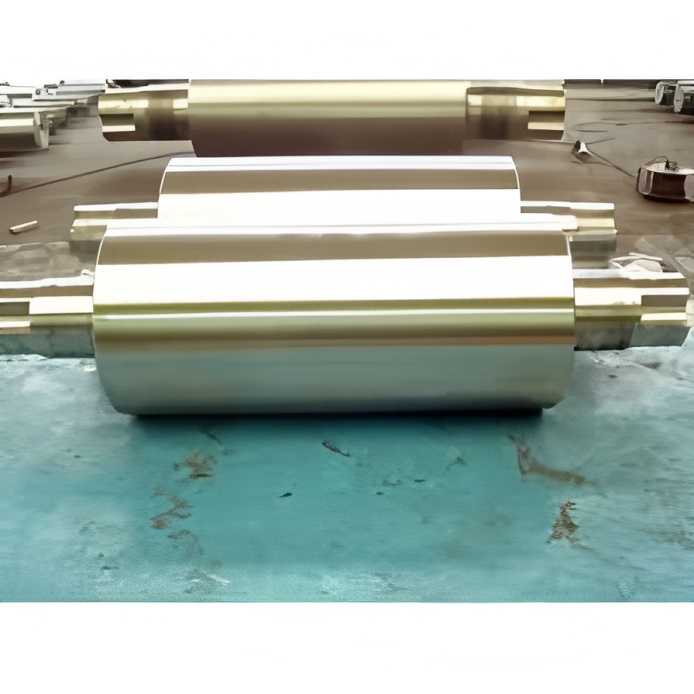

High-Speed Steel (HSS) rolls represent a cornerstone of modern metal rolling technology, particularly in the steel industry. Developed from traditional high-speed tool steel, these rolls are engineered with an enhanced chemical composition, primarily higher carbon and vanadium content, to deliver superior performance. Since their pioneering application in Japan in 1988, HSS rolls have become indispensable in rolling mills worldwide. Their adoption spans a wide range of applications, from the demanding environment of hot strip mill finishing stands to section mills, pipe mills, bar and wire rod mills, and even cold strip mills. The strategic use of HSS as a rolling mill roll material dramatically increases rolling throughput, extends campaign life, and reduces the frequency of roll changes and grinding. This translates to a higher operational rate for the mill, lower energy consumption, and ultimately, reduced production costs while significantly improving the surface quality and dimensional accuracy of the final product.

This article provides a comprehensive analysis of the composition and function of alloying elements in HSS rolls. We will explore their profound influence on the roll’s microstructure and resulting properties, examine the latest developments in cast HSS roll materials, and discuss the impact of advanced modification treatments and microalloying on performance. This information serves as a critical guide for mill operators, roll shop specialists, and engineers aiming to harness the full potential of high-performance HSS rolls.

Compositional Characteristics of High-Speed Steel Rolls

The foundation for most modern HSS rolls is the W6Mo5Cr4V2 (M2) grade of high-speed steel. However, to meet the extreme demands of rolling applications, the composition is significantly modified. The primary distinction lies in a substantially higher carbon (C) and vanadium (V) content. This enrichment is designed to increase the volume fraction of hard carbides, which are the key to the material’s exceptional wear resistance. In a typical HSS roll, the carbide volume fraction ranges from 9% to 15%, a notable increase from the sub-8% found in conventional tool steels. This carbide volume is predominantly determined by the chemical composition, with the solidification cooling method having a more limited influence.

Key compositional strategies include:

- Elevated Carbon and Vanadium: These elements are increased to promote the formation of extremely hard MC-type (vanadium carbide) primary carbides, which are crucial for maximizing wear resistance.

- Increased Chromium Content: Higher levels of chromium (Cr) encourage the formation of M₇C₃-type carbides. These carbides not only contribute to wear resistance but are particularly effective at improving the roll’s resistance to surface roughening and thermal cracking, which helps maintain product quality and can reduce rolling forces.

- Niobium for Centrifugal Casting: For rolls produced via centrifugal casting, niobium (Nb) content, typically below 5%, is often added. Niobium helps to mitigate elemental segregation that can occur due to the density differences between various alloying elements during the casting process.

The precise chemical composition of a high-speed steel work roll or backup roll is tailored to its specific application, considering the type of rolling mill, the rolling conditions (hot vs. cold), and the manufacturing method. The table below presents a comparison of typical compositions from leading international mill roll manufacturers.

Table 1: Composition Comparison of HSS Rolls (wt%)

| Element | GP (China) | HITACHI (Japan) | AKERS (Sweden) | NSC (Japan) |

|---|---|---|---|---|

| C | 1.50–2.20 | 1.50–3.50 | 1.50–2.50 | 1.50–2.40 |

| Si | 0.30–1.00 | 0.30–1.00 | 0.20–1.20 | — |

| Mn | 0.40–1.20 | 0.30–1.50 | 0.20–1.20 | — |

| Cr | 3.00–8.00 | 2.00–7.00 | 3.00–12.00 | 2.00–10.00 |

| Ni | 0.00–1.50 | < 5.00 | 0.50–2.00 | < 5.00 |

| Mo | 2.00–8.00 | < 10.00 | 1.00–8.00 | 2.00–10.00 |

| V | 2.00–9.00 | 3.00–10.00 | 1.00–8.00 | 2.00–10.00 |

| W | 0.00–8.00 | < 20.00 | 0–5.0 | 2.00–10.00 |

| Co | ≤ 8.00 | < 10.00 | — | ≤ 10.0 |

| Nb | ≤ 5.00 | — | 0–5.0 | ≤ 10.0 |

The Critical Role of Alloying Elements

The exceptional properties of HSS rolls—high hardness, red hardness (hot hardness), hardenability, and wear resistance—are a direct result of a carefully balanced combination of alloying elements. The primary elements include Chromium (Cr), Vanadium (V), Tungsten (W), and Molybdenum (Mo), with additions of Niobium (Nb), Cobalt (Co), and Nickel (Ni) for specific property enhancements.

- Chromium (Cr): Typically 4–8%

Chromium is a versatile and essential element. It is a primary contributor to the material’s hardenability, ensuring that a hard martensitic structure can be formed throughout the roll’s working layer during heat treatment. It also enhances red hardness and forms Cr-rich M₇C₃ carbides, which are vital for improving resistance to thermal shock and surface roughening during hot rolling. - Tungsten (W) & Molybdenum (Mo): Mo 3–8%, W < 5%

These elements are powerful carbide formers that significantly improve tempering resistance and red hardness, allowing the roll to maintain its hardness and strength at the elevated temperatures of hot rolling. Molybdenum is often preferred over tungsten, especially in centrifugally cast rolls, as its lower density reduces the tendency for segregation. A common practice is to maintain Mo content at 3–5% while keeping W below 2% to ensure a homogeneous microstructure. - Vanadium (V): Typically 4–9%

Vanadium is the key to superior wear resistance. It forms extremely hard MC-type vanadium carbides (VC), which can have a Vickers hardness (HV) exceeding 3000. These fine, hard carbides are dispersed within the steel matrix, providing exceptional resistance to abrasive wear. Vanadium also acts as a grain refiner. However, excessive vanadium can lead to the formation of coarse, brittle carbide networks along grain boundaries, which can cause cracking and surface adhesion issues (pickup). - Carbon (C): Typically 1.5–2.5%

Carbon is the backbone of the alloy. Its content must be carefully balanced to form the desired volume of hard carbides with elements like V, W, and Mo, while also ensuring the roll matrix (the material surrounding the carbides) achieves the necessary hardness and toughness after heat treatment. The optimal carbon content is determined empirically, taking into account the concentrations of other carbide-forming elements. - Other Key Elements:

- Niobium (Nb): As mentioned, Nb is added to refine the as-cast structure and reduce the segregation of vanadium carbides in centrifugally cast rolls.

- Cobalt (Co): Added in amounts up to 8%, cobalt improves the red hardness and high-temperature wear resistance of the matrix but can reduce overall toughness.

- Nickel (Ni): Typically kept below 2%, nickel is added to enhance the toughness of the matrix. However, higher amounts can promote the retention of soft austenite after quenching, which is generally undesirable.

Manufacturing and Development of HSS Roll Materials

High-performance HSS rolls typically exhibit a tensile strength of around 800 MPa and a working hardness in the range of 75–90 HSc (Shore C). The dominant manufacturing methods include:

- Centrifugal Casting: This is the most common method used by roll foundries due to its high efficiency, simplicity, and ability to produce a composite roll with a high-performance HSS outer shell and a more ductile core.

- Continuous Pouring for Cladding (CPC): A specialized process for creating a bimetallic roll.

- Hot Isostatic Pressing (HIP): A powder metallurgy process that produces a fully dense, homogeneous material with an extremely fine and uniform microstructure, offering the highest level of performance but at a significantly higher cost.

Recent development efforts in HSS roll material have focused on further enhancing performance and reducing costs. Key trends include increasing Cr and Mo content to form more robust carbides, improving thermal stability, and exploring the use of Boron (B). Boron is a potent hardening agent that can form extremely hard borides, enhancing wear resistance at a lower cost compared to some traditional alloying elements. This has led to research into low-alloy, high-boron HSS roll compositions.

Advances in Microstructure and Performance via Modification

A primary challenge with as-cast HSS rolls is the presence of coarse, net-like eutectic carbides that form during solidification. This microstructure can lead to relatively low strength and toughness, making the rolls susceptible to spalling and fracture. To overcome this, advanced modification and microalloying treatments are employed to refine the structure.

- Rare Earth (RE) Modification: The addition of small amounts of rare earth elements (like Ce, La) has a powerful refining effect on both the austenite grains and the carbide morphology. RE elements modify the shape of carbides from coarse networks to finer, more isolated particles, which significantly improves both fracture toughness and impact toughness.

- Titanium (Ti) Microalloying: Titanium forms highly stable TiC particles at very high temperatures. These particles act as effective nucleation sites for the primary MC carbides during solidification, leading to a much finer and more uniformly distributed carbide structure. This refinement enhances both toughness and wear resistance.

- Composite Modification: Some of the most advanced treatments involve a composite addition of multiple elements, such as a rare earth-titanium-nitrogen-potassium combination. This synergistic approach has been shown to dramatically improve thermal fatigue resistance and inhibit crack propagation, which is critical for rolls used in hot rolling mills.

The tangible benefits of these treatments are evident in the mechanical properties. The table below illustrates the significant improvement in the properties of an HSS roll with the addition of a rare earth modification treatment.

Table 2: Effect of RE Modification on Mechanical Properties of HSS Rolls

| Treatment | Hardness (HRC) | Red Hardness (HRC) | Fracture Toughness (MPa·m¹/²) | Impact Toughness (J·cm⁻²) |

|---|---|---|---|---|

| With RE | 66.3 | 61.5 | 25.91 | 10.17 |

| Without RE | 64.5 | 60.4 | 22.08 | 7.38 |

As shown, the RE-modified roll exhibits superior hardness, a remarkable ~17% increase in fracture toughness, and a ~38% increase in impact toughness.

Conclusion and Future Outlook

The performance of high-speed steel rolls is intrinsically linked to the precise control of their chemical composition and microstructure. The strategic use of alloying elements like chromium, vanadium, molybdenum, and tungsten is fundamental to achieving the desired balance of wear resistance, toughness, and thermal stability. Future development will likely continue to focus on creating more cost-effective compositions, such as low-alloy, high-boron HSS rolls, without compromising performance.

Furthermore, the refinement of the as-cast structure through modification and microalloying treatments is a critical area of ongoing research. While these techniques have proven to significantly enhance strength, toughness, and wear resistance, achieving consistent and stable process control on an industrial scale remains a key challenge for mill roll manufacturers. Continued research into the solidification behavior, heat treatment response, and in-service performance characteristics of these advanced materials will be essential to broaden the application of high-performance HSS rolls and drive further efficiency and quality gains in the global steel rolling industry.