The Crucial Role of Mill Rolls in Modern Rolling Operations

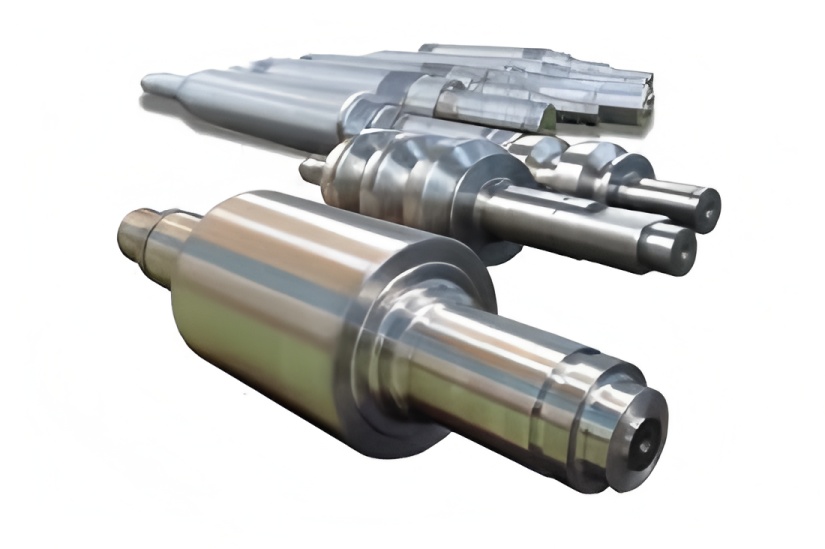

In the demanding environment of a rolling mill, the rolls themselves are the heart of the operation. As the primary components that come into direct contact with the material being processed, their performance dictates not only the final quality of the rolled products but also the overall production efficiency and operational costs. The selection of rolling mill roll material is therefore a critical decision for any steel or non-ferrous metal producer. While various materials like indefinite chilled cast iron, semi-steel, and high-chromium cast iron have been traditionally used, High-Speed Steel Composite Rolls (HSS Rolls) have emerged as a superior solution, offering a distinct set of advantages that make them indispensable for both hot and cold rolling applications.

HSS rolls are celebrated for their high carbide hardness, exceptional thermal stability, and robust hardenability. These properties translate into superior wear resistance and a strong defense against thermal cracking, which are common failure modes in high-temperature rolling. Furthermore, their ability to form a stable, protective oxide film during operation significantly extends their service life, leading to longer roll change cycles and reduced downtime. This article provides a comprehensive examination of the design principles, manufacturing processes, and finishing techniques for high-speed steel composite rolls, offering valuable insights for mill roll manufacturers and end-users alike.

Material Requirements and Bimetallic Composite Design

During the rolling process, the working layer of the roll is subjected to immense pressure, causing the plastic deformation of the rolled metal. To withstand these forces, the roll’s surface must possess a combination of seemingly contradictory properties: extreme hardness for wear resistance and sufficient toughness to prevent catastrophic fracture under localized overloads or impacts. This challenge is elegantly solved by the bimetallic composite design.

Most modern, high-performance rolls, including HSS rolls, are not monolithic. They are engineered as composite structures:

- The Working Layer (Shell): This is the outer layer of the roll, made from a high-wear-resistance material. For HSS rolls, this layer is a specialized high-speed steel alloy rich in hard carbides.

- The Core and Neck (Core): This inner part of the roll is made from a material with high toughness and strength, typically nodular (ductile) cast iron. This core provides the structural integrity needed to handle the immense bending forces and torque transmitted during rolling.

This composite approach, achieved through advanced preparation processes like centrifugal casting, allows the roll to deliver the best of both worlds: a surface that resists wear and maintains its profile for longer, and a core that can absorb shock and prevent brittle failure. HSS composite rolls are a prime example of this sophisticated material engineering.

Composition Design of the HSS Working Layer

The performance of an HSS roll is fundamentally determined by the chemical composition of its working layer. Each alloying element plays a specific role in forming the desired microstructure, which consists of hard carbide particles embedded in a tough, tempered martensitic matrix. Achieving the right balance is key to optimizing the work roll material properties.

| Alloying Element | Typical Content (%) | Primary Function & Effect |

|---|---|---|

| Carbon (C) | 1.8% – 2.8% | Forms hard alloy carbides (primary wear resistance). A portion dissolves in the matrix to enable hardening and secondary hardening during tempering. The C/V ratio is critical. |

| Chromium (Cr) | 4.0% – 6.0% | Forms M₇C₃ and M₂₃C₆ carbides. Improves hardenability, corrosion resistance, and thermal shock resistance. Enhances surface finish by preventing material adhesion. |

| Tungsten (W) & Molybdenum (Mo) | W: 5.0% – 8.0% Mo: 3.0% – 5.0% | Key elements for red hardness and tempering resistance. Form extremely hard M₆C carbides. Mo can substitute for W and is highly effective in preventing temper brittleness. |

| Vanadium (V) | 4.0% – 6.0% | Forms ultra-hard MC (Vanadium Carbide, VC) particles (HV > 3000). VC refines grain size and provides exceptional wear resistance. Excessive V can make grinding difficult. |

| Other Elements (Nb, Co, Ni) | Nb: < 1.5% Co: < 5.0% Ni: < 2.0% | Niobium (Nb) refines carbides and reduces segregation. Cobalt (Co) improves high-temperature wear resistance. Nickel (Ni) enhances matrix toughness but can increase retained austenite. |

Detailed Analysis of Key Elements

Carbon (C): To achieve high wear resistance, the working layer must contain a significant volume of hard carbides, typically over 15%. Carbon is the foundational element for this. However, its content must be carefully controlled. If too low, the volume of hard phases is insufficient. If too high, it can lead to coarse, segregated carbides (ledeburite), which drastically reduce the roll’s toughness and make it prone to spalling.

Vanadium (V): Vanadium’s strong affinity for carbon results in the formation of extremely hard Vanadium Carbide (VC) particles. These primary carbides are stable even at high austenitizing temperatures, effectively pinning grain boundaries and preventing grain growth. This dual action of providing wear-resistant particles and refining the grain structure makes vanadium a critical element for high-performance HSS rolls.

Manufacturing Process: Centrifugal Casting Control

While several forming methods exist, such as spray deposition (Osprey) and hot isostatic pressing (HIP), horizontal centrifugal casting remains the most prevalent and cost-effective method for producing HSS composite rolls. The process involves pouring the molten HSS alloy into a rapidly rotating cylindrical mold. The centrifugal force pushes the heavier, denser metal to the outer wall, creating a fine-grained, dense, and defect-free shell. After the shell has solidified, the molten ductile iron for the core is poured in, fusing metallurgically with the HSS layer.

Despite its advantages, the process presents two major challenges that require precise control: alloy element segregation and casting cracks.

Control of Alloy Element Segregation

Due to differences in density, heavy elements like Tungsten (W) and Molybdenum (Mo) tend to segregate towards the outer surface under centrifugal force, while lighter elements can concentrate inwards. This can lead to inconsistent properties across the working layer. Advanced techniques are employed to mitigate this:

- Niobium (Nb) Addition: Adding niobium promotes the formation of (V, Nb)C composite carbides. The density of these carbides is closer to that of the molten steel, reducing their tendency to segregate and resulting in a more uniform carbide distribution.

- Electromagnetic Stirring (EMS): Applying a magnetic field during solidification induces stirring in the molten metal, counteracting the effects of centrifugal force and thermal convection. Studies have shown that a magnetic field of just 0.053T can reduce the segregation of W, Mo, and V by 60.6%, 31.9%, and 62.7%, respectively, leading to a significant improvement in macrohardness uniformity.

Control of Casting Cracks

The high alloy content and the thermal stresses generated during solidification and cooling make HSS rolls susceptible to cracking. Control measures focus on both metallurgy and process dynamics:

- Molten Steel Pretreatment: A multi-stage inoculation and modification process is used. This involves precise additions of ferrovanadium, rare earth magnesium alloy, and ferrotitanium at different stages of tapping and pouring to refine the grain structure and modify the solidification morphology, thereby increasing crack resistance.

- Variable-Parameter Casting: Modern systems employ variable-speed rotation, variable-flow pouring, and variable-speed cooling. By dynamically adjusting these parameters, the temperature gradients and internal stresses within the solidifying shell can be managed, effectively preventing the formation of thermal cracks.

Grinding Process Control for HSS Rolls

The final stage of manufacturing is mill roll grinding, a precision machining process that determines the final surface quality of the roll. A flawless roll surface is essential for producing high-quality rolled products free from defects. Common grinding defects like scratches, chatter marks, and burns must be avoided. This requires careful selection of the grinding wheel and optimization of grinding parameters.

Grinding Wheel Selection

The choice of grinding wheel is critical. Key factors include:

- Abrasive: Due to the extreme hardness of the carbides in HSS, the abrasive must be even harder. Single-crystal corundum is often the optimal choice, offering high toughness and cutting efficiency.

- Grain Size: Coarse grains (e.g., 30 mesh) are used for rough grinding, while fine (e.g., 80 mesh) and very fine grains (e.g., 120 mesh) are used for finishing and polishing to achieve the required surface roughness (Ra).

- Bond: Ceramic bonds are preferred for their rigidity, thermal stability, and shape retention during rough and fine grinding. For mirror finishing, resin bonds are often used.

- Hardness: The wheel hardness must be matched to the roll’s surface hardness. A softer wheel is generally used for a harder workpiece to allow for self-sharpening and prevent wheel loading and workpiece burn.

Optimized Grinding Parameters

Achieving a defect-free surface with high geometric accuracy depends on the precise control of speeds and feeds. The following table provides typical parameters for grinding HSS rolls.

| Grinding Stage | Grinding Wheel Speed | Roll Speed | Longitudinal Feed Rate |

|---|---|---|---|

| Rough Grinding | 25 – 35 m/s | 20 – 40 r/min | 200 – 400 mm/min |

| Fine Grinding | 25 – 35 m/s | 15 – 28 r/min | 100 – 250 mm/min |

| Polishing / Mirror Grinding | 15 – 20 m/s | 10 – 15 r/min | 80 – 150 mm/min |

Conclusion: A Holistic Approach to Quality

The design and manufacture of high-speed steel composite rolls is a complex, multi-disciplinary process that demands meticulous attention to detail at every stage. From the initial alloy composition design to the final grinding pass, each step has a profound impact on the roll’s ultimate performance and service life. By optimizing the chemical balance, employing advanced casting technologies to ensure structural integrity, and implementing precision grinding techniques, manufacturers can produce HSS rolls that deliver unparalleled wear resistance, thermal stability, and reliability.

For rolling mill operators, investing in high-quality HSS rolls translates directly into improved product quality, higher productivity, and lower total cost of ownership. As the industry continues to push the boundaries of material strength and production speeds, the importance of a scientifically grounded, holistic approach to roll design and manufacturing will only continue to grow.