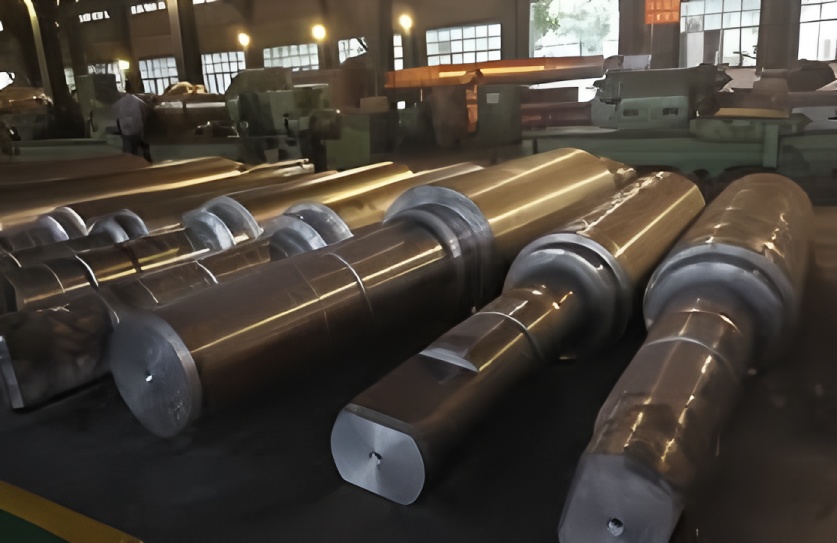

Rolls serve a critical function in steel rolling operations. Under heavy workloads and increased production of medium-thin plates, most work rolls develop edge cracks. These cracks typically propagate, causing small-scale spalling at roll edges and forming continuous or intermittent defects. Persistent cracking can lead to large-scale material separation, ultimately rendering rolls unusable.

Primary Causes

Work roll edge defects generally originate from these factors:

Overloading at roll body ends due to exacerbated work roll positive bending

Support roll body end chamfer geometry and dimensions. During rolling, contact pressure between support and work rolls creates stress concentrations or excessive instantaneous stress at roll edges, initiating micro-cracks

Extended service life causing excessive wear, leading to localized end overload and initial crack formation that propagates over time

After encountering work roll edge defects in production, comprehensive investigation identified optimal work roll profile grinding, crown control, and support roll chamfering as key solutions.

Experimental Approach

Work Roll Profile Testing (units: mm)

Initial trapezoidal profile with 1400mm center width, 0.0002 crown, 4300mm base width, following 180-degree sinusoidal curve.

Test results showed excessive center thinning and thickness variation across plates. Edge stress reduction maintained stresses within controllable range.

Subsequent testing implemented parabolic profile with 180-degree sinusoidal curve, 0.0002 height, 450mm edge extension, creating Ω-shaped configuration.

This modified profile demonstrated excellent performance with minimal thickness variation and controlled edge stress, effectively preventing edge defects.

Final specification combines support roll chamfer (30000 radius, 400 length) with work roll profile: 180-degree sinusoidal curve, 450mm edge extension, 0.0002 height (crown adjustable with wear), forming the optimal Ω-shaped configuration.

Follow-up Assessment

Proper roll profile grinding and appropriate edge chamfering eliminated edge defects. Monitoring confirmed absence of micro-cracks and early plastic deformation, with effective edge stress control and maintained hardness within operational range. Continuous inspection enabled prompt issue identification and resolution.

Conclusions

Appropriate support roll edge chamfering significantly impacts support roll service life

Strategic work roll profile management, accounting for wear progression and crown development, effectively extends roll service life