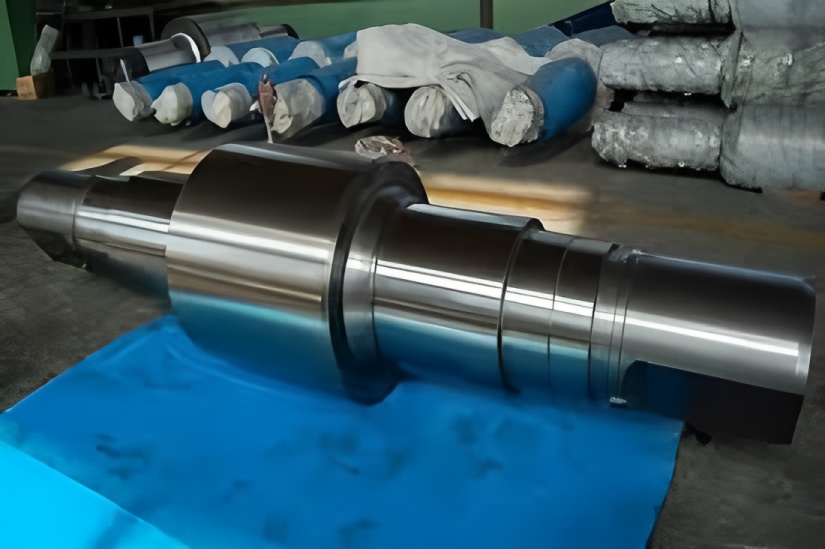

Rolls are in direct contact with the strip during rolling and serve as essential tools in hot rolling production. Reducing roll consumption can effectively lower production costs, improve efficiency, increase mill operating rates, and ensure the surface quality of hot-rolled products. Given the substantial roll consumption in hot-rolled strip production, identifying measures to reduce roll usage and extend service life is highly significant.

Optimized Roll Change Cycles

2.1 Roughing Work Rolls

The original roll change cycle for roughing rolls was 2.5–3.8万吨 (wt). This has been gradually extended while monitoring roll wear, strip profile, and surface quality. The current cycle is stabilized at 3.8–4.5 wt, which does not adversely affect strip shape or surface quality and extends roll service life.

2.2 Finishing Backup Rolls

As the rotational speeds of F1–F7 rolls vary significantly, their wear rates also differ. The former uniform change cycle of 10–15 wt was unreasonable. The current segmented roll change cycle is detailed in Table 1.

Since implementing segmented roll changes, roll throughput has increased by approximately 14.94%, extending roll life. Additionally, statistics show a reduction in waviness when rolling thin gauge materials near the end of roll service.

Correct Handling of Rolling Accidents

Severe rolling accidents directly increase roll consumption. Proper handling of affected rolls is essential to minimize losses.

3.1 Jammed Strip Incident

When a jam occurs, cooling water should be stopped immediately and the top roll lifted to avoid contact with the strip. After strip removal, change and slowly cool the roll. If immediate replacement isn’t possible and cracks are minor, idle the work rolls without water for 5–10 minutes to allow even temperature distribution before resuming rolling.

3.2 Roll Pick-Up Incident

First remove any adhered steel. Then conduct a detailed inspection of the affected area, including hardness checks, crack detection, and nondestructive testing. The damaged zone must be removed to ensure uniform surface hardness and eliminate cracks.

Innovative Grinding Strategies for Roll Defects

Unplanned roll changes from August 2015 to April 2016 show that accident-related rolls accounted for 69% of all replacements. Proper and timely handling after incidents can minimize damage, extend service life, and reduce consumption.

Below are treatment methods for common roll defects:

4.1 Thermal Cracking

Most thermal cracks result from sudden temperature changes during jam or pile-up accidents.

Treatment: For R1 and F1–F4 rolls, continue using those with minor cracks online under stable rolling conditions. The cracks may close (closed cracks do not propagate and may diminish over time) and gradually disappear.

4.2 Steel Buildup on Rolls

Caused by tail whipping or piled strips adhering to the roll.

Treatment: For severe buildup over 3 mm thick, first turn off the adhered material. After removal, inspect the roll surface for cracks or spalling. Determine the grinding depth based on damage severity to eliminate defects without excessive material removal.

4.3 Edge Spalling of Work Rolls

Caused by stress concentration at the roll shoulder.

Treatment: Since the shoulder does not contact the strip directly, remove the spalled section, add a ground chamfer, and adjust the chamfer angle and method of the supporting roll to improve stress distribution.

4.4 Backup Roll Defects

Backup rolls do not contact the strip directly and have lower hardness than work rolls, but are costly. Conventional grinding is often not suitable.

Treatment: For edge damage, increase the chamfer length during grinding. Treat residual defects with an angle grinder and smooth the surrounding area to prevent spalling propagation. For mid-body damage, conventional grinding followed by angle grinding and blending is recommended.

Roll Profile Optimization

Based on production experience, F1–F4 rolls were switched from concave to HVC profiles. The negative crown of F5–F7 rolls was also increased to improve surface stress distribution. This achieves better strip shape control and reduces roll consumption.

Additional Measures to Reduce Roll Consumption

Develop and practice response procedures for various rolling incidents to improve emergency handling and minimize roll damage.

Establish reasonable roll inspection standards to ensure quality and avoid unnecessary losses.

Select qualified roll suppliers and customize high-quality rolls in terms of material and hardness to match mill production characteristics.

Introduce high-speed steel rolls for the front finishing stands once production stabilizes, to further reduce consumption.

Conclusion

The optimized HVC and negative crown roll profiles improve stress distribution and enhance strip crown control, contributing to product quality.

Adjusting roll change cycles, improving incident response, and proper accident roll handling increase per-roll throughput and extend service life while maintaining product quality.

Measures for treating accident rolls reduce unnecessary grinding, thereby lowering labor intensity.