CORRECT OPERATION AND USAGE

Optimal Rolling Parameter Control

Rolling Force Management

Precisely regulate rolling force based on strip material, thickness, and width specifications

Prevent excessive pressure that causes roller deformation and fatigue damage

Implement precise pressure sensors and control systems for cold rolling applications

Example: Maintain appropriate force ranges for thin plate cold rolling to minimize wear

Speed Regulation

Adjust rolling speeds to balance production efficiency and equipment protection

Monitor friction-induced heat generation to prevent thermal deformation

Example: Set appropriate speeds for hot-rolled strip production considering steel grade and thickness

Tension Control

Maintain optimal strip tension to ensure stable operation and prevent deviation

Balance tension levels to avoid both excessive local wear and strip instability

Implement precise tension control based on strip properties and process requirements

OVERLOAD PREVENTION

Operate within rated load capacities for all backup rolls

Distribute production tasks strategically to prevent continuous overload

Implement overload protection systems for emergency situations

Example: Install automatic shutdown systems when force exceeds safety thresholds

WORKING ENVIRONMENT OPTIMIZATION

Temperature and Humidity Control

Maintain workshop temperature between 20-25°C

Regulate humidity levels at 40-60%

Implement air-conditioning systems for precision rolling operations

Install cooling systems (water cooling) for hot rolling processes

Contamination Prevention

Reduce dust through air filtration systems and regular cleaning

Ensure air cleanliness meets required standards for sensitive applications

Example: Implement high-efficiency filtration in electronic strip rolling facilities

COMPONENT AND MATERIAL SELECTION

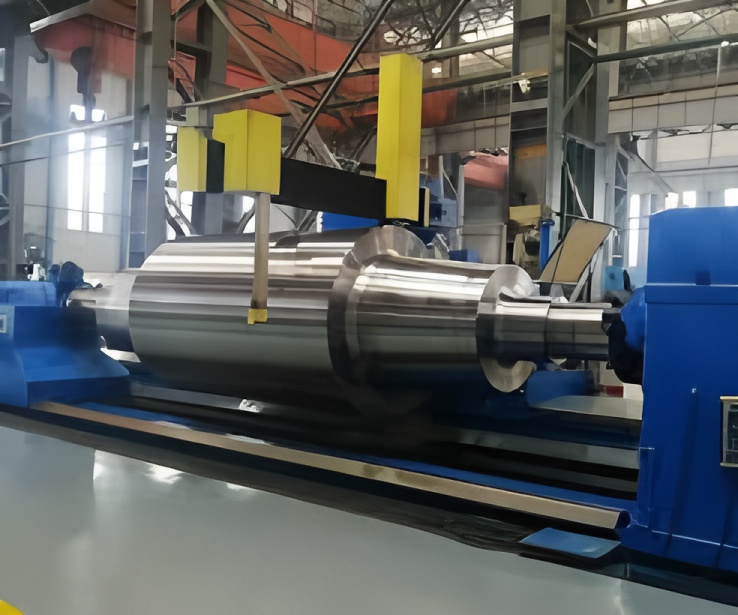

Roller Material Specifications

Select materials based on specific rolling processes and requirements

Utilize high-chromium cast iron and alloy steel for cold rolling applications

Consider composite materials or special coatings for specialized applications

Example: Choose wear-resistant materials for high-precision electronic material processing

Bearing and Seal Quality

Select high-precision rolling bearings with superior load capacity

Choose seals with excellent oil resistance and durability

Ensure proper sealing to prevent contamination and lubricant leakage

Example: Utilize precision-machined bearings for high-speed, high-load operations