Frequently Asked Questions: Six-High Reversing Mill Cold Rolling Technology

What causes strip breakage?

Material Issues: Severe defects in incoming strips—such as edge pinching, overfill, under-pickling, over-pickling, uneven thickness, edge or center waves—can lead to breakage.

Equipment Failure: Electrical, control system, or hydraulic malfunctions—commonly tension fluctuations, loss of tension, or halts in hydraulic/emulsion systems.

Operational Errors:

Unaddressed strip deviation or material defects.

Improper pass schedule with excessive reduction or high rolling force.

Excessive entry/exit tension.

Failure to adjust speed for thickness variations from previous passes.

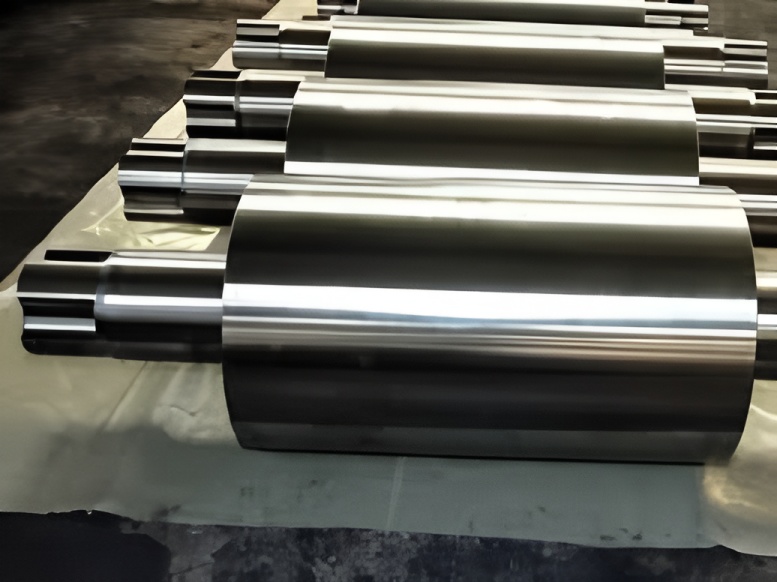

Roll Failure: Breakage due to roll bursting.

How to handle strip breakage?

Immediately stop the mill, remove the strip from the housing, and extract the intermediate or backup rolls. Inspect for roll damage and replace if necessary. Clear broken strip debris from the mill frame. Check the main drive shaft and safety pins; replace any broken components. After roll changes, run the first coil at reduced speed and carefully inspect strip surface quality.

What causes thermal scratches?

Insufficient emulsion flow during high-speed rolling leads to inadequate heat removal, causing roll temperature rise and breakdown of the oil film on the strip. High-speed roll slippage and relative friction between the strip and roll can also cause thermal scratches. These are typically shallow and barely detectable by touch.

How to control thermal scratches?

Increase emulsion flow rate.

Lower emulsion temperature.

Address roll slippage: verify roll diameter input, check for excessive speed difference between upper/lower work rolls, ensure consistent intermediate/backup roll roughness, and adjust if rolling force is too low.

What causes hard scratches?

Extended work roll service reduces surface roughness, while excessive pass deformation causes roll slippage on the strip. Hard scratches often occur in high-reduction passes (e.g., Pass 1 or 2) and are visibly deeper.

How to control hard scratches in Pass 1/2?

Replace rolls promptly when roughness is low. Additional measures:

Increase exit tension and reduce entry tension.

Start with a thicker setting and gradually reduce to target thickness.

Avoid abrupt speed reductions to prevent thickness fluctuations.

If slip marks appear, adjust exit thickness to reduce reduction and change rolls after the pass.