Description

This article introduces the characteristics and advantages of high-speed steel rolls. By summarizing the usage conditions, accident handling, and performance outcomes of high-speed steel rolls in a fully continuous bar production line in a steel plant’s third rolling area, it highlights their application potential and benefits.

Keywords: High-speed steel rolls, high-nickel-chromium cast iron rolls, bar rolling

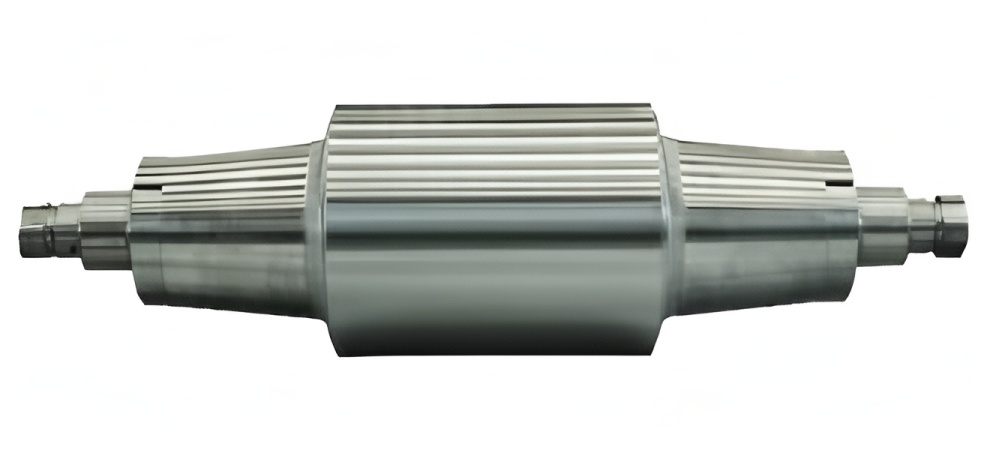

Introduction to High-Speed Steel Rolls

High-speed steel rolls contain significant amounts of alloying elements such as W, Mo, Cr, V, and Co. High carbon and vanadium content promotes the formation of high-hardness MC-type carbides, improving wear resistance. A higher chromium content facilitates Mc-type carbides, enhancing surface roughness resistance and reducing rolling force. Cobalt improves red hardness, making these rolls suitable for hot rolling applications. High-speed steel rolls exhibit superior hardness, thermal crack resistance, and thermal shock resistance compared to high-nickel-chromium cast iron rolls, with wear resistance being 4–5 times greater. Although high-speed steel rolls are being rapidly adopted in hot rolling production across China, optimizing their use remains a significant challenge in the steel industry.

Usage of High-Speed Steel Rolls

Cooling Requirements

High-speed steel rolls have a high thermal expansion coefficient. Uneven temperature distribution can lead to irregular thermal expansion and abnormal oxide film spalling, affecting thermal crown and roll gap accuracy. The key to controlling oxide film thickness, thermal crown, and minimizing thermal cracks lies in managing roll surface temperature.

During hot rolling, the instantaneous contact temperature reaches 600–750°C. It is crucial to rapidly cool the roll surface from 700°C to below 300°C after exiting the contact arc to prevent further oxidation. Operating in a fully water-cooled environment after the high-temperature zone promotes the formation of a protective oxide film.

Optimizing cooling water distribution—such as increasing flow at the outlet and middle of the roll, lowering cooling pipe height, and using flat nozzles instead of conical ones—can significantly reduce surface temperature. Allocating 75% of cooling water to the outlet side helps maintain the roll surface below 50°C. The cooling system should feature annularly arranged nozzles to ensure consistent and sufficient water coverage in the roll groove. The main nozzle near the exit guide should deliver 30% of the total water volume at a spray angle of 20–30°, targeting the area just after the material exits. Water pressure should be maintained at 4–6×10⁵ Pa, with a minimum flow of 500 L/min per groove. Water should be filtered to minimize solid particles and prevent roll damage.

Maintenance of High-Speed Steel Rolls

Given their high brittleness and relatively low accident resistance, ensuring stable mill operation is essential to prevent cobbles and bearing failures. In case of jamming or pile-ups:

Immediately stop water cooling.

Lift the top roll to detach the material.

Quickly clear any accumulated stock on the bottom roll.

Allow the heated groove to cool naturally in air.

After resolving the incident, switch to a different groove (2–3 grooves away) before resuming operation. Never direct cooling water onto an overheated groove. If changing grooves is not feasible, replace the roll and allow it to cool naturally before reuse. Direct water contact will cause cracking.

An oxide film forms on the groove surface during rolling—initially orange or light blue, turning dark blue or purple-black with continued use. If the film becomes too thick or gets scratched, it may spall, causing “meteor spots” or, in severe cases, surface roughening and pitting. Thermal cracks due to fatigue are inevitable, but if unaddressed or not fully removed during grinding, they can propagate and lead to spalling. Thus, proper usage conditions and diligent maintenance are critical to maximizing roll life.

Application Benefits of High-Speed Steel Rolls

These rolls address multiple shortcomings of high-nickel-chromium cast iron rolls, such as low wear resistance, frequent roll and groove changes, tendency to spall, poor surface quality, and dimensional inaccuracy. Their use enhances equipment capacity, ensures smooth production, reduces operator workload, and delivers significant economic benefits.

Improved Production Stability and Technical Metrics

With high-nickel-chromium rolls, grooves in the K2 pass required replacement every shift, and K1 passes needed 3–4 changes per shift. High wear limited production capacity. After switching to high-speed steel rolls, the rolling capacity per groove increased 3–4 times. Groove replacement in the K2 pass dropped to once every 3–4 shifts, and K1 passes to once per shift. Reduced wear decreased roll change time, improving mill utilization and production stability.

A major advantage in key finishing passes is the long-term stability of the material profile, reducing the need for adjustments and ensuring consistent dimensional accuracy. This leads to stable finished product size with minimal negative deviation fluctuation. Excellent wear resistance and high rolling capacity also ensure consistent size across multiple strands in two- and three-cut splitting, improving sizing rate, yield, and finished product rate by 0.1%, and reducing scrap rate by approximately 50%.

Reduced Roll Consumption

Field results show that high-speed steel rolls increase rolling tonnage per groove, reduce regrinding volume, extend service life, and improve finished product size stability and surface quality. For example, in rebar rolling, the single-groove rolling tonnage for pre-cutting and finished product stands increased by at least three times, while grinding volume decreased by one-third.

Conclusion

High-speed steel rolls demonstrate excellent cost efficiency in bar splitting and rolling applications. They significantly reduce roll and groove change time, improve operational rates, and support stable, high-volume production with enhanced product quality.