Description:

This article introduces the chemical composition and performance characteristics of cast high-speed steel rolls, analyzes issues encountered in their practical application, and proposes corresponding improvement measures based on actual conditions. It provides valuable reference for the effective use of high-speed steel rolls.

Keywords: High-speed steel rolls, hot strip mill, roll application

Chemical Composition and Performance Characteristics of High-Speed Steel Rolls

Chemical Composition

High-speed steel is a high-alloy tool steel containing significant amounts of W, Mo, Cr, V, and Co. To enhance performance, carbon content is often increased. The exact chemical composition varies to suit different rolling conditions and processes.

Key features of high-speed steel roll composition include:

High C and V content to form high-hardness MC-type carbides and improve wear resistance.

Elevated Cr content to promote Mc-type carbides, improving surface roughness resistance and reducing rolling force.

For centrifugally cast rolls, Nb content is kept below 5% to minimize segregation caused by density variations among alloying elements.

Co enhances red hardness. In hot rolling applications, adding Co (generally below 10%) significantly improves wear resistance.

Performance Characteristics

High-speed steel, traditionally used for tools and dies, is heat-treated by quenching at 1250–1320°C followed by tempering at 500–600°C. The resulting structure consists of tempered martensite, carbides, and a small amount of retained austenite, achieving hardness up to HRC 75–88.

Carbides in the roll are mainly MC, M₆C, and small amounts of M₂C. Increasing V content raises the volume fraction of MC-type carbides and reduces fishbone-like M₆C carbides.

The combination of high-hardness carbides (MC, M₂C, M₆C) and a stable martensitic matrix provides excellent hardenability and minimal hardness drop during service. This ensures consistent wear resistance. Comparative data show that the wear per rolling unit for high-speed steel rolls is about 0.019 mm, versus 0.092 mm for indefinite chill rolls—making the latter nearly five times more prone to wear.

Problems in the Application of High-Speed Steel Rolls

Strip Shape Issues

The high wear resistance of high-speed steel rolls means they are reground only after multiple uses. However, wear heredity and accumulation make strip shape difficult to control over extended use. Key shape indicators are flatness and crown. The typical control strategy uses early stands (F1–F3) to manage crown and later stands (F4–F7) to control flatness.

In practice, with thin strips or specific finished specifications, roll shape changes significantly. Although CVC position and bending force can be adjusted, excessive roll shape variation causes rapid strip shape deterioration, affecting rolling stability.

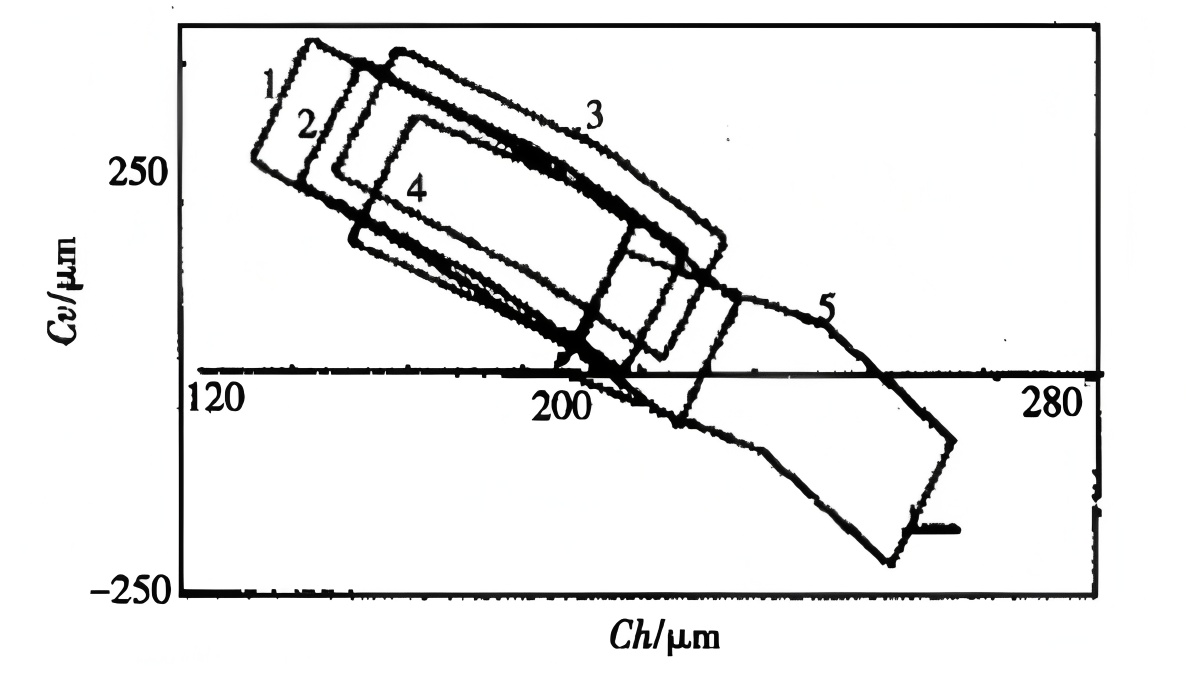

Figure 1 illustrates the crown adjustment range for a new unworn roll. Curves 2–5 show adjustment domains with wear-induced crown values of 0.05 mm, 0.1 mm, 0.15 mm, and 0.2 mm superimposed on the CVC curve. Up to 0.15 mm, CVC adjustment remains nearly linear and stable. However, at 0.2 mm wear, the adjustment becomes nonlinear, impairing crown control capability.

With repeated use, wear often exceeds 0.2 mm, especially in rear stands like F4, where edge wave becomes severe. This is due to cumulative wear over multiple grinding cycles. The high temperature and pressure in front stands cause significant roll expansion, influencing strip elongation and subsequent stands. Wear models, typically based on new rolls, fail to account for cumulative usage, complicating shape control in later stands.

Oxide Film Spalling

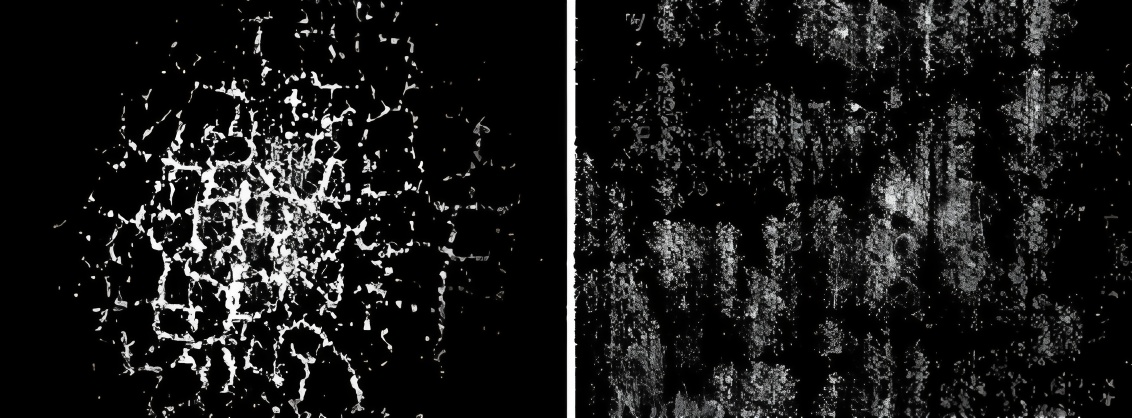

In hot rolling, work rolls experience temperature cycles from 700–800°C down to about 60°C per revolution. An oxide film forms under oxidizing conditions, protecting the roll surface. Microscopic examination reveals a network of cracks in this film on high-speed steel rolls.

As rolling continues, thermal and rotational fatigue cause cracks to grow and propagate along carbides into the roll. Cracks may form both perpendicular and parallel to the surface. If these connect, strong shear stress between the roll and strip can cause spalling, leading to banded defects.

Sticking (Roll Pick-up)

When rolling thin strip, tail “flicking” can cause broken strip fragments to adhere to the roll—a phenomenon not observed with conventional rolls. Causes include:

Microstructure and Composition: High-speed steel has low carbon content and composition similar to strip steel, promoting adhesion. Unlike indefinite chill rolls that contain 2–5% free graphite (reducing sticking), high-speed steel lacks free graphite.

Oxide Film: In early stands, a protective oxide film forms due to longer contact time and lower speed. In rear stands, higher speeds shorten oxidation time, resulting in a thinner, less protective film that increases sticking risk. If not addressed, sticking can lead to crack propagation and accidents.

Improvement Measures

Based on the above analysis, improvements focus on managing wear and protecting the oxide film.

Wear Calculation Model Optimization

Original wear models did not account for cumulative wear over multiple uses. Although wear is low, it is measurable—especially after rolling high-hardness grades—and affects CVC and bending force settings.

The improved model saves the wear crown value when rolls are removed and uses it as the initial value in subsequent uses. This alignment between calculated and actual wear improves setting accuracy.

Oxide Film Protection

The oxide film reduces friction, prevents sticking, and extends roll life. High-speed steel forms this film faster than conventional rolls, reducing initial wear. Protecting this film is crucial.

Reasonable Load Distribution

Excessive rolling force damages the oxide film. Reducing load on critical stands helps protect it. If scale defects appear on strips from a specific stand, redistributing load to other stands or shifting some to roughing can help. Maintaining load distribution supports thicker oxide films on work rolls.

Roll Temperature Control

Controlling roll temperature—mainly through cooling water management, especially in F2 and F3—is essential. Too little water leads to a thick, brittle oxide film prone to spalling; too much water results in a thin film and rough surface, causing scale defects. Adjusting water flow to keep roll temperature within an optimal range is effective—e.g., stepping cooling from 80% to 100% to stabilize the oxide film.

Use of Rolling Lubricants

High-speed steel rolls have high friction coefficients, increasing rolling force by 10–20% under similar conditions. Hot rolling lubrication is effective in reducing rolling force and protecting equipment. Lubrication is especially needed given the multi-cycle use and gradual degradation of the oxide film.

Roll Configuration Strategy

Considering strip surface quality, roll consumption, and grinding reduction, rational roll configuration is critical. For high-surface-quality products (e.g., automotive exterior panels), assigning rolls with appropriate surface grades based on quality requirements is essential.

Conclusion

High-speed steel rolls offer significantly better wear resistance ( nearly 5× that of indefinite chill rolls).

Multi-cycle use impacts strip shape; optimizing the wear calculation model is an effective solution.

Load distribution optimization, rolling lubrication, and temperature control help establish and maintain the oxide film.

Future work should focus on enhancing finished product surface quality and reducing roll consumption.