Keywords: rough rolling, mill rolls

Description: This article outlines critical points in the control of the rough rolling process. Operators must fully understand and carefully implement these guidelines.

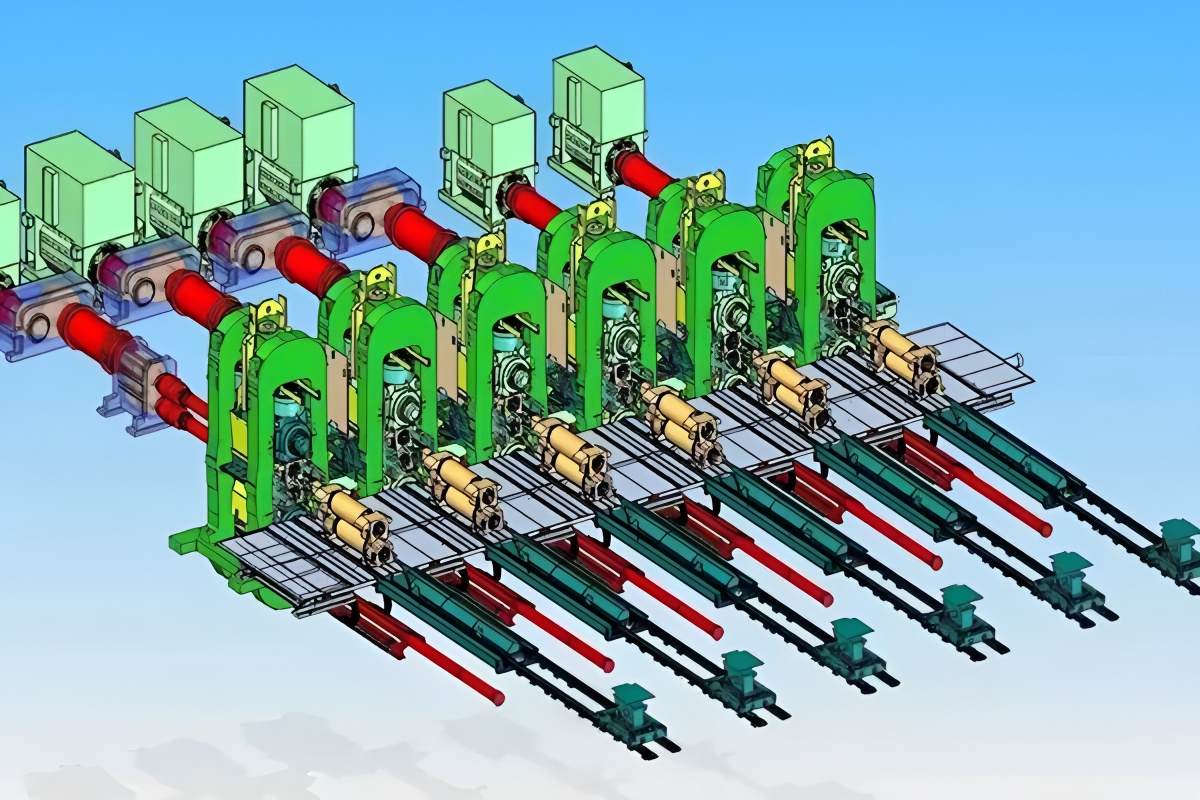

Key Considerations for Rough Rolling Process Control

1. Width Control

The rough rolling stand must ensure proper engagement of the short-stroke function on the edger and vertical rolls.

Width control requires coordination between roughing and finishing mills. Although roughing is primarily responsible for width, finishing operators should also monitor final product width and promptly report issues to the roughing station.

Width compensation often requires input of a modification inheritance function. Operators must closely observe width changes after adjustments. During specification changes, initial width deviation may occur due to inaccurate learning coefficients, but this error decreases gradually. Timely adjustment of compensation coefficients is essential. Past quality incidents at our plant have resulted from failure to update width compensation parameters—such human errors must be avoided.

2. RT2 Temperature Control Principles

RT2 temperature is primarily regulated through heating furnace operations. If needed, the rolling line can also make minor adjustments by modifying rolling rhythm, speed, or descaling passes.

If RT2 temperature deviates from the target range, operators should first identify the cause by checking:

Whether the tapping rhythm is too fast, causing delays somewhere in the line;

Whether descaling water, cooling water, or reverse spray water are functioning abnormally;

Whether the temperature curve is normal or if measurement is affected by environmental factors;

Whether rough rolling speed, reduction, and other process parameters are within norms.

If rolling line conditions are normal, contact furnace and process personnel to decide whether rolling parameters should be adjusted.

For identified abnormalities:

Contact instrumentation specialists for sensor issues;

Inform process specialists for parameter abnormalities;

If tapping rhythm is incorrect, notify the furnace to adjust heating—but note that temperature changes take time. Meanwhile, RT2 temperature can be temporarily controlled by modifying rolling rhythm, speed, or descaling passes.

Note: Manual intervention in rolling speed under load is strictly prohibited.

If RT2 temperature is too high, the R2 operator can limit speed上限, increase descaling passes, or appropriately delay processing.

Descaling pass settings should not be altered under normal conditions. Adjustments are only temporary measures under abnormal circumstances to prevent scrap. For example, reducing descaling may be appropriate for short slab delays. For persistent RT2 abnormalities, roughing operators must notify the furnace to adjust temperature. Process personnel must approve any changes to descaling passes.

If RT2 is too low, inform the furnace to slow or stop tapping and increase temperature. Simultaneously, notify the finishing mill about the temperature so they can prepare. If necessary, R2 may reduce descaling water—provided surface quality is maintained—to ensure rolling stability and avoid scrap.

As slab thickness decreases pass-by-pass, the effect of speed limits and descaling adjustments on temperature becomes more pronounced. Operators should select appropriate passes based on actual conditions. When adding descaling passes, consider the effect of R2 exit descaling on instruments—avoid exit descaling on the last pass. If incoming material temperature is too low, stop rolling decisively to prevent accidents.

R2 operators should continuously monitor the Raytek thermometer screen to track intermediate slab temperature distribution. If the temperature difference across the slab width exceeds 15°C in any pass, record the slab ID, furnace number, and deviation value in the shift log, and notify the furnace to adjust.

3. Camber (Sickle) Control

For difficult-to-roll specifications, assign an operator to observe camber and direct R1 and R2 correction. R2 can also use the centerline curve and head/tail shapes on the optimized cutting screen to monitor camber.

If significant camber is detected after R1, immediately notify the rolling line to control rhythm, switch to manual mode, and adjust the Swivel value to maintain a reasonable intermediate slab shape.

R2 should adjust the Swivel value immediately upon detecting camber after any pass to correct it and ensure good slab shape.

R2 reductions decrease pass-by-pass. During passes 1–5 (sometimes up to 7), adjust the Swivel value following a “large to small” pattern corresponding to reduction. Note that Swivel can be pre-set or adjusted incrementally during rolling.

R2 operators must adjust every pass. It is prohibited to neglect adjustments in early passes and only correct in the final pass.

Each station should promptly inform upstream and downstream processes of camber issues to facilitate coordinated control.

The Swivel value adjustment range for the R2 mill is -2 to +2.

4. Buckling and Warping Control

Under normal conditions, the SKI value in the roughing area should be within ±4. If adjustment within this range is ineffective, check upper/lower work roll cooling, roll surface condition, or temperature differences across the slab. Document the situation and notify relevant personnel.

Severe warping usually results from abnormal slab temperature. Prolonged delays or equipment停留 can cause the top surface to cool excessively, leading to warping. Burner billets or reverse-charged billets with abnormal heating are also prone to buckling and warping. Operators should anticipate and adjust the SKI value accordingly. Terminate rolling if the situation is severe.

Production personnel should communicate with the furnace to improve temperature uniformity based on observed warping patterns. If SKI adjustment is ineffective, consider increasing the effective adjustment distance (e.g., from 0.5m to 0.7m).

Additionally, note that the R1 entry descaling header lacks a collision guard—avoid passes that may risk equipment impact.

5. Preventing R2 Work Roll Thermal Cracks

Early production experience showed that parking hot intermediate billets in the R2 mill and activating descaling water for cooling—though faster for scrap handling—causes severe thermal cracks on the rolls due to prolonged contact with hot slabs. This increases roll grinding and reduces service life; in severe cases, it can lead to roll surface damage. Therefore, roughing operators must:

Never intentionally keep hot billets on work rolls. If a billet is stuck due to tripping or other reasons, notify process and roll shop personnel immediately—remove and inspect the rolls.

During manual stripping, to prevent thermal cracking from rapid cooling/heating, turn off work roll cooling water before passing hot billets through the roll gap. Do not press “Fault Ackn” to cancel the quick stop before manual reversal—doing so will restart cooling water.

If using descaling water to cool billets during manual stripping, manually position the slab when activating water. Monitor descaling water level and pressure to ensure proper operation.

6. Thin Gauge Rolling Notes

(1) Strengthen camber correction for thin and narrow specs, especially in the last 2–3 passes of R2, as well as early passes of R1 and R2. Ensure roughing intermediate slab deviation ≤20mm.

(2) Roughing operators are responsible for monitoring and reporting RT2 temperature. For thin specs, assist and supervise the furnace to keep RT2 at the upper limit. R2 may adjust descaling passes if needed.

(3) If rolling becomes unstable, slow the rhythm, contact process specialists, and confirm that furnace, roughing, and finishing parameters meet requirements. If necessary, stop to check rolls, nozzles, wipers, etc. Do not continue rapid production if multiple billets are unstable—this may cause scrap and prolonged downtime.

7. Roll Change Inspection and Verification

To ensure timely and orderly roll changes, operators should:

Before changing rolls, remove scale and debris from the R2 work roll bearing housing, lock baffle, and track. Ensure no obstructions when extracting rolls.

After roll extraction, clean out scrap metal and debris from the roll housing area.

Prepare spare nozzles and splash guards before roll changes. After roll removal, inspect and replace any missing, blocked, or damaged nozzles or guards.

Record the exact time of roll installation/removal and any cobbles during the roll’s service life on the roll sheet. Return the old roll sheet to the grinding shop when installing new rolls.

Each shift must maintain and hand over the roll sheet with the shift log. The oncoming shift should verify the roll sheet. If lost, note this in the log to clarify responsibility.

8. Notes when R1 Mill is Idle

If the R1 mill cannot production, set it to idle mode (refer to “Modification of Rough Rolling Process Parameters and Control of Process Elements”). Note that R2 reduction must be redistributed: without R1, the first pass of R2 becomes the initial rolling pass, and the bite thickness is much greater than normal—especially with large SSP width reduction, where inlet thickness can exceed 250mm. Therefore, reduce the first pass reduction from 48mm max to 35–40mm to prevent slipping or severe buckling.

If R2 load is excessive, consider increasing R2 passes or reducing intermediate slab thickness to ensure safe rolling.

9. Other Considerations

Operators must control production rhythm to avoid delays. If delays occur due to malfunctions or specification changes, notify the entire line to adjust tapping rhythm immediately. Do not allow more than three consecutive delayed billets.

For abnormal process conditions, contact specialists immediately. Temporary parameter changes are allowed with specialist approval, but should not be used long-term. Restore settings after normalization. Operators should maintain detailed logs: record abnormalities, temporary measures, and specialist recommendations in the shift handover report. This helps other operators understand situations, supports problem analysis, and clarifies responsibility (showing that adjustments were specialist-approved).