Low-Carbon and High-Efficiency Rebar Production Process Practice (Part II)

Description: This paper presents the main energy-saving and consumption-reduction technologies used in rod and wire production in China and analyzes the shortcomings of these technologies. The new low-carbon, high-efficiency rebar production process has fully achieved the goals of low-carbon and efficient production.

Keyword: Rebar production process, low-carbon

Control Rolling and Cooling Process Under Multi-Line Cutting Production Mode (H2)

Control Principle Overview (H3)

The latest national standard for rebar products is GB/T1499.2-2018, which requires the metallographic structure to consist of ferrite and pearlite, with no tempered martensite present in the base metal. In other words, compliant building rebar must meet the following: the microstructure should be primarily ferrite plus pearlite without other phases affecting performance; the grain size should be no coarser than Grade 9.

Control Rolling (H4)

Rebar control rolling involves reasonable regulation of deformation temperature and cumulative deformation to increase ferrite nucleation sites during rolling. This is combined with staged cooling after rolling to achieve microstructural refinement and improve the comprehensive mechanical properties of the steel.

The first stage of control rolling: The workpiece is processed in the first finishing mill unit, with temperature controlled between 900–950°C. At this point, the rebar is in the austenite non-recrystallization zone, with cumulative deformation ranging from 60% to 75%.

The second stage of control rolling: When the workpiece is rolled through the second finishing mill unit, the surface temperature is controlled near Ar₃ (800–850°C), with cumulative deformation between 35% and 50%. Deformation along austenite grain boundaries provides nucleation sites for austenite-to-ferrite transformation. In this stage, rolling is conducted in the austenite non-recrystallization region. After multiple passes, austenite grains are elongated, deformation zones increase and distribute uniformly, providing more nucleation sites and facilitating the formation of fine and uniform ferrite grains in the subsequent phase transformation.

Controlled Cooling (H4)

After rolling, a graded cooling method is adopted to control the cooling of the workpieces, ensuring that the cross-section of the rebar base consists of pearlite and ferrite and avoiding the formation of martensite or other low-temperature phases. Grain size and the proportion of ferrite are controlled within a suitable range to guarantee that the mechanical properties and microstructure of the rebar meet national standards.

In summary, the control rolling system depends on two key factors: cumulative deformation and deformation temperature.

Cumulative deformation is mainly related to the pass system, number of rolling passes, and deformation per pass. Deformation temperature control is primarily influenced by the layout of water cooling lines and the cooling capacity of water tanks.

Control Rolling Process in Traditional Multi-Cut Production (H3)

The precision roll pass design in the traditional multi-line cutting process includes flat rolls, vertical box passes, pre-cut passes, cutting passes, flat rolls, and finishing passes. A schematic of the controlled rolling pass system is shown in Figure 3. The water tank is positioned before the finishing mill, so deformation after water cooling occurs over six finishing passes, with cumulative deformation well exceeding 50%. Additionally, the finishing pass sequence includes pre-cut and cut passes, which involve irregular deformation, making it difficult to cool the rolling stock uniformly and adversely affecting the rolling control outcome.

Control Rolling Process in Improved Multi-Cut Production (H3)

Improvement Plan (I) (H4)

The improved precision roll pass design consists of a pre-cut oval pass followed by an oval pass after the water tank. A schematic of the controlled rolling pass system is shown in Figure 4. The water tank is installed between stands K3 and K2. Control rolling mainly occurs in the last two passes, with cumulative deformation between 35% and 50%. The oval pass system ensures uniform deformation and fully complies with control rolling theory.

The cooling mill material type is round, so the cooling nozzle is designed as an annular nozzle that sprays cooling water uniformly around the rolling stock. The annular water gap can be adjusted via spacers. The tank includes three channels: the left and right channels are used for simultaneous cooling of two lines (e.g., φ20mm×2, φ22mm×2, φ25mm×2), while the middle channel is used for single-line cooling (φ28–φ50mm).

Improvement Plan (II) (H4)

The improved precision roll pass design consists of a cut pass after the water tank and a finishing flat roll. The water tank is placed between stands K4 and K3, basically meeting the requirements for deformation temperature and cumulative deformation. The cooling nozzle is designed as a rectangular nozzle, and each set of rectangular nozzles ensures uniform cooling of the rolling stock.

Post-Rolling Graded Cooling Process (H3)

The graded cooling method introduces an intermediate air-cooling process in addition to the traditional controlled cooling approach. The main purpose of air cooling is to reduce the temperature difference between the surface and the core after water cooling. Graded cooling effectively minimizes this temperature difference during cooling control, thereby promoting the formation of a uniform room-temperature microstructure and avoiding low-temperature phases on the surface.

Practical Application of the Improved Control Rolling Process (H2)

Mill Layout of the Production Line (H3)

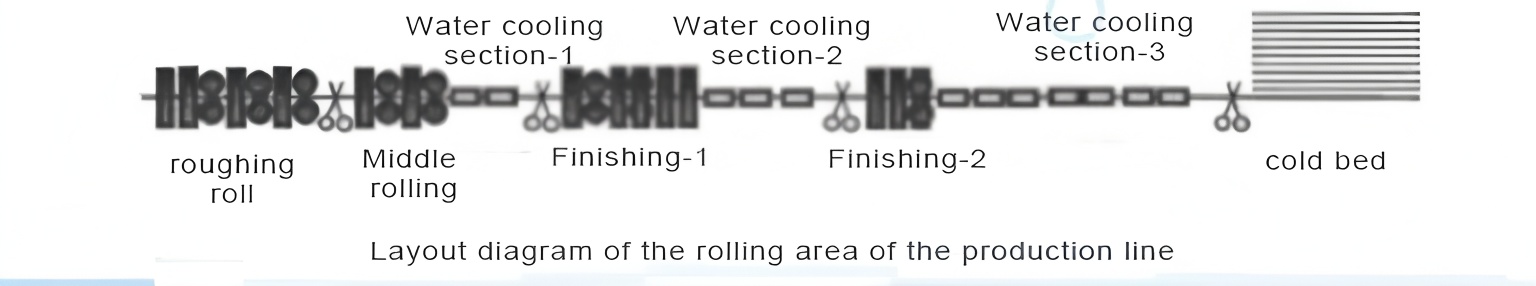

The mill layout incorporates both Improvement Plan (I) and Improvement Plan (II), forming a controlled rolling and cooling process capable of full specifications and high production capacity. The rolling area layout of the production line is shown in Figure 9.

Mill Arrangement (H4)

The rolling mill is divided into four units: 6 roughing mills, 4 intermediate mills, 6 finishing mills in the Rod Finishing-1 unit, and 3 finishing mills in the Rod Finishing-2 unit, totaling 19 stands.

Layout of the Through-Type Water Cooling Device (H4)

The through-type water cooling device is arranged in three sections: the first is located between the centerline of the last stand of the intermediate mill and the first stand of the Finishing-1 unit; the second is between the last stand of the Finishing-1 unit and the first stand of the Finishing-2 unit; the third is between the last stand of the Finishing-2 unit and the flying shear, consisting of a water tank and a return guide groove.

Metallographic Structure of Rebars Produced via the New Process (H3)

All finished products are rolled from the last two or three stands of the finishing mill unit. A pre-water cooling device is installed before and after the Finishing-1 unit to promote controlled rolling and provide more nucleation sites for post-rolling phase transformation. After the Finishing-2 unit, a graded through-type water cooling device controls the cooling rate of the rolling stock, maintaining the surface within the martensite-bainite transition zone and preventing austenite grain growth.

Conclusion

This paper has introduced the main energy-saving and consumption-reduction technologies in rod and wire production in China and analyzed their limitations. In response to the production demand for high output and low consumption in manufacturing plants, a new low-carbon, high-efficiency rebar production process has been proposed and successfully implemented in a new production line at a steel plant, fully achieving the goal of low-carbon and high-efficiency production.

(1) The new process enables direct rolling technology in high-productivity rebar production lines. The practical production line achieves a daily output between 5500 and 5800 tons, a direct rolling rate of 75%, and CO₂ emissions of 63.2 kg per ton of steel.

(2) The improved multi-cut control rolling process introduces controlled cooling technology under multi-strand production mode, enabling the production of 400E rebar (specifications below 25 mm) without adding microalloy elements.