High-speed steel (HSS) rolls are widely used in modern steel rolling mills for hot and cold strip mills, bar and wire rod mills, and section mills. Compared with conventional alloy cast iron or indefinite chill rolls, HSS rolls offer significantly higher wear resistance and longer campaign life, especially in finishing stands where surface quality and dimensional tolerance are critical.

For mill roll manufacturers, roll shops, and steel producers, understanding the materials and properties of high-speed steel rolls is crucial for selecting the right rolling mill roll material, optimizing rolling schedules, and reducing roll consumption per ton of steel. This article summarizes the key characteristics, chemical composition ranges, hardness profiles, and application guidelines of HSS work rolls and backup rolls, based on industrial practice and published data.

Overview of High-Speed Steel (HSS) Rolls in Rolling Mills

In rolling mills, rolls are the core tools that directly contact and deform the metal. Mill rolls can be classified by:

- Position: work rolls, backup rolls, pinch rolls, table rollers, continuous casting rollers

- Manufacturing route: cast rolls, forged rolls, tungsten carbide composite rolls

- Material: indefinite chill iron, high chrome cast iron, high-speed steel, forged steel, tungsten carbide rolls

High-speed steel rolls belong to the category of alloy tool steels with high carbon and high alloy content. They are commonly used as:

- Work rolls in hot strip mill finishing stands

- Work rolls in cold rolling mills (4‑Hi, 6‑Hi, and tandem mills)

- Section and bar mill finishing rolls

- Backup rolls with HSS cladding in specific high-wear applications

Under normal rolling conditions, HSS rolls typically achieve service life more than three times that of conventional alloy cast iron rolls, especially in terms of tonnage rolled per regrind and total campaigns before scrap.

Fundamental Material Requirements for HSS Mill Rolls

The material of a high-speed steel roll must satisfy several stringent requirements to withstand the complex thermo-mechanical loading in hot and cold rolling mills. The most important material properties include:

1. High Hardness

HSS rolls are designed with high surface hardness to provide precise control of metal deformation and surface finish. Typical hardness levels are:

- Hot strip mill work rolls: HRC 60–63

- Cold rolling mill work rolls: HRC 60–65

- Small section / bar mill HSS rolls: HRC 58–63, depending on stand and reduction

Hardness must be uniform not only on the surface but also through the working layer thickness (typically 30–80 mm, depending on roll size and design). This uniformity is directly related to hardenability and to the type, morphology, and distribution of carbides.

2. High Wear Resistance

During rolling, work rolls are subjected to continuous friction and abrasion from hot or cold strip, oxide scales, and lubricants. HSS rolls achieve high wear resistance primarily by:

- High volume fraction of hard carbides (MC, M2C, and M6C)

- Alloying with vanadium (V), niobium (Nb), tungsten (W), molybdenum (Mo), and chromium (Cr)

- Optimized heat treatment to obtain tempered martensite with stable dispersion of carbides

Compared with high chrome cast iron rolls, HSS rolls show significantly lower wear rate under the same rolling conditions, which directly reduces roll consumption and roll grinding frequency.

3. High Heat Resistance and Thermal Stability

In hot rolling, work roll surfaces may reach instantaneous temperatures up to 600–700 °C, followed by rapid cooling from spray water. HSS rolls must therefore maintain hardness and wear resistance at elevated temperature (secondary hardening) and resist:

- Softening at high temperature

- Thermal fatigue cracking

- Fire cracking and shelling

Alloy design with W, Mo, and Cr promotes the formation of high-temperature-stable carbides and secondary hardening during tempering, which improves hot hardness and resistance to thermal degradation.

4. Good Thermal Conductivity

Good thermal conductivity helps remove heat quickly from the roll surface into the roll body and cooling water channels, reducing surface temperature gradients and thermal stresses. HSS rolls have higher alloy content than conventional cast iron rolls, which can reduce thermal conductivity; therefore, roll manufacturers must carefully balance alloying elements and core materials to ensure sufficient heat dissipation.

5. Uniform Hardness and Microstructure

Uniform hardness and a well-controlled microstructure throughout the working layer are essential to avoid localized deformation, uneven wear, and stress concentration. High hardenability and strict heat treatment allow HSS rolls to achieve:

- Very small hardness gradient from surface to the bottom of the working layer (generally < 3 HRC)

- Fine tempered martensite with a stable distribution of primary and secondary carbides

- Minimal segregation and porosity through advanced casting or forging processes

Typical Chemical Composition of HSS Rolls

The exact chemical composition of HSS rolls varies by manufacturer and application (hot strip, cold strip, section mill, etc.), but they generally contain high carbon and high alloy contents. The main alloying elements are C, Cr, Mo, W, V, and sometimes Nb. The carbides formed are mainly MC (rich in V/Nb), M2C (rich in Mo/W), and M6C, which provide high hardness and wear resistance.

| Element | Typical Range (wt%) | Function in HSS Rolls |

|---|---|---|

| C (Carbon) | 1.4 – 2.2 | Forms carbides and martensite; increases hardness and wear resistance. |

| Cr (Chromium) | 3.0 – 8.0 | Improves hardenability, oxidation resistance, and secondary hardening. |

| Mo (Molybdenum) | 3.0 – 6.0 | Promotes M2C/M6C carbides, enhances hot hardness and temper resistance. |

| W (Tungsten) | 3.0 – 8.0 | Works with Mo to form complex carbides; improves red hardness and wear resistance. |

| V (Vanadium) | 2.0 – 6.0 | Forms very hard MC carbides; refines grain; increases abrasion resistance. |

| Nb (Niobium) | 0.5 – 2.0 (optional) | Enhances MC-carbide formation and wear resistance in some HSS grades. |

| Si (Silicon) | 0.3 – 1.2 | Deoxidizer; controls graphitization; affects matrix hardness. |

| Mn (Manganese) | 0.3 – 1.5 | Improves hardenability and toughness; helps control segregation. |

Note: Exact composition depends on mill roll manufacturer, roll size, and specific application. The values above are typical ranges reported for industrial HSS work rolls and should be fine‑tuned according to stand position and mill design.

Microstructure and Carbide Types in HSS Rolls

The superior performance of HSS rolls is closely related to their microstructure. After proper heat treatment, the structure of a typical HSS work roll consists of:

- Matrix: tempered martensite, sometimes with lower bainite

- Primary carbides: MC (V/Nb-rich), M2C and M6C (Mo/W-rich), distributed in the matrix

- Secondary carbides: finely dispersed carbides precipitated during tempering, contributing to secondary hardening

MC carbides (V, Nb) are extremely hard and improve abrasive wear resistance, especially against oxide scale and high-stress sliding. M2C and M6C carbides provide hot hardness and temper resistance, ensuring stable performance at elevated temperature.

Performance Characteristics of High-Speed Steel Rolls

Based on their composition and microstructure, HSS rolls exhibit a set of characteristic behaviors that differentiate them from conventional roll materials.

1. Stable High Hardness from Surface to Core of Working Layer

HSS rolls are designed with high hardenability, so that the working layer achieves nearly uniform hardness throughout its thickness. This uniform hardness provides:

- Consistent wear resistance across the roll barrel

- Stable roll profile during long rolling campaigns

- Reduced risk of differential wear and shape defects

2. Formation of Protective Oxide Film

Under appropriate cooling and lubrication conditions, a thin, dense, and adherent oxide film forms on the surface of HSS rolls during hot rolling. This film:

- Reduces direct metal-to-metal contact

- Decreases friction and roll wear

- Improves resistance to fire cracking and surface oxidation

However, the low friction coefficient of the oxide film may increase the risk of strip slipping, especially in light reductions or low-tension conditions. Mill operators must therefore carefully adjust rolling loads, tension, and coolant flow to maintain stable bite and elongation.

3. High Wear Resistance but Lower Accident Resistance

Compared with alloy cast iron or forged steel work rolls, HSS rolls provide much better wear resistance but generally lower “accident resistance,” meaning they are more sensitive to:

- Severe overloading or sudden changes in reduction

- Cooling failure, blocked nozzles, or uneven water distribution

- Mechanical shocks, cobbles, and severe strip misalignment

Therefore, the actual performance of HSS rolls depends not only on roll quality but also on the operating conditions, mill cooling design, roll pass design, and maintenance practices.

4. Thermal Expansion and Roll Shape Change

HSS rolls have relatively high thermal expansion coefficients. In plate and strip mills, temperature gradients and differential heating across the barrel can cause:

- Barrel crown changes

- Edge build-up or center wear

- Variations in strip profile and flatness

To obtain the full benefit of HSS work rolls, mills must optimize the cooling system layout (nozzle pattern, flow, pressure, and distribution) and revise roll crown / roll profile design to account for the specific thermal behavior of HSS materials.

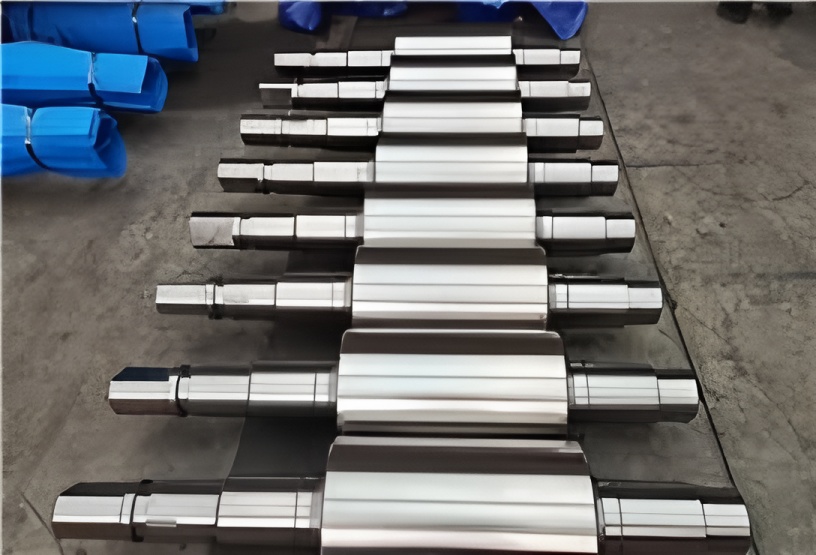

5. High Neck Strength via Composite Structures

HSS rolls are often produced as compound rolls: a high-speed steel outer working layer is metallurgically bonded to a tough core material, such as:

- Alloy ductile iron

- Graphite steel

- Forged steel

This design ensures high wear resistance at the surface while maintaining high neck strength and good overall toughness, which is essential for high-speed rolling mills and for stands subject to high separating forces.

Comparison: HSS Rolls vs. Alloy Cast Iron Rolls

The decision to upgrade from alloy cast iron rolls to HSS work rolls requires a clear understanding of the technical and economic differences between these mill roll materials. The table below summarizes typical performance comparisons under similar rolling conditions.

| Parameter | High-Speed Steel Work Rolls | Alloy Cast Iron Work Rolls |

|---|---|---|

| Typical surface hardness | HRC 60–65 | HRC 45–60 (depending on grade) |

| Wear resistance | Very high (primary MC, M2C carbides) | Moderate to high (M3C carbides, graphite) |

| Service life (tonnage per mm wear) | ≈ 2–4 times that of alloy cast iron | Baseline |

| Accident resistance | Lower; sensitive to severe overload and thermal shock | Generally higher; more tolerant of abnormal events |

| Oxide film behavior | Thin, dense, adherent; low friction but risk of slipping | Less stable and often more easily spalled |

| Roll grinding frequency | Significantly reduced due to slower wear | Higher: more frequent roll changes and grinding |

| Typical application | Finishing stands of hot and cold strip mills, section finishing | Roughing stands, intermediate stands, lower-duty applications |

Key Parameters of HSS Work Rolls for Production Reference

For mill roll specialists and roll shop engineers, several parameters must be specified when selecting or purchasing HSS rolls for hot or cold rolling mills:

- Roll type: work roll, backup roll, edger roll, or pinch roll

- Mill type: hot strip mill, cold strip mill, bar mill, wire rod mill, section mill, or plate mill

- Stand position: roughing, intermediate, or finishing stands

- Roll dimensions: barrel diameter, barrel length, neck diameter, overall length

- Hardness and hardness profile: target HRC at surface and depth of hardened layer

- Core material: alloy ductile iron, graphite steel, or forged steel

- Expected tonnage per regrind and total campaign life

- Allowed minimum barrel diameter at end of life

Typical hardness profile requirements for HSS work rolls are given in the indicative table below (exact values must be specified by each mill and roll designer).

| Depth from Surface | Typical Hardness (HRC) | Remarks |

|---|---|---|

| Surface (0–3 mm) | 60 – 65 | Maximum hardness for wear resistance and shape control. |

| 10 mm | 59 – 64 | Slight gradient; still high wear resistance. |

| 30 mm | 58 – 63 | Core of working layer; hardness must remain relatively uniform. |

| Bottom of working layer | 55 – 60 | Transition to core material; controlled gradient to avoid stress. |

Application of HSS Rolls in Different Types of Rolling Mills

High-speed steel rolls are used in many types of mills. For engineers seeking to classify rolling mills and select suitable roll materials, some typical applications are summarized below.

1. Hot Strip Mills and Plate Mills

In hot strip mills and plate rolling mills (two-high, four-high, and sometimes tandem configurations), HSS work rolls are mainly used in finishing stands (F1–F7). They significantly improve:

- Roll campaign life and tonnage per regrind

- Strip surface quality and thickness tolerance

- Productivity by reducing roll changes and roll shop workload

Roughing stands often still use high chrome cast iron or forged steel rolls because they require higher accident resistance and impact toughness. For edge rolling, special HSS edger rolls or tungsten carbide composite rolls may be employed in high-wear positions.

2. Cold Rolling Mills (4-Hi, 6-Hi, and Tandem Mills)

In cold rolling mills, HSS work rolls for cold strip mills provide excellent surface finish and extended life, especially in tandem cold mills and 4‑Hi reversing mills. In these applications:

- Work rolls are often HSS or forged steel with HSS overlay

- Backup rolls may be forged steel or high-strength alloy steel

- Coolant chemistry and filtration are critical to avoid surface damage

Flatness control devices such as work roll bending and backup roll shifting must be carefully set to accommodate the lower wear rates of HSS rolls, so that roll profile evolution is predictable throughout the campaign.

3. Bar, Wire Rod, and Section Mills

In long product rolling, including two-high, three-high, and tandem rolling mills, HSS rolls are frequently used in the last few stands to improve dimensional accuracy and surface quality. They are often combined with:

- Forged steel rolls in roughing and intermediate stands

- Tungsten carbide rolls or tungsten carbide composite rolls in wire rod finishing blocks or sizing mills

For shape rolling, such as angles, channels, and beams, careful roll pass design and roll shop maintenance are necessary to avoid shape defects arising from non-uniform wear or misalignment. HSS rolls are especially effective in stands where wear of hot rolling mill rolls is typically severe due to high reduction and high speed.

Work Rolls, Backup Rolls, and Composite Roll Design

In four-high and six-high rolling mills, both work rolls and backup rolls play important roles:

- Work rolls directly contact the strip and mainly require high wear resistance, high surface hardness, and good thermal behavior.

- Backup rolls support the work rolls. They must have high strength, sufficient hardness, and excellent resistance to contact fatigue and spalling.

HSS is mainly applied to the working layer of work rolls, while backup rolls are usually made from:

- Forged steel with high cleanliness and controlled microstructure

- Cast steel or high-strength spheroidal graphite iron in certain positions

For composite roll designs used in hot and cold strip mills, a typical configuration is:

- HSS outer shell (working layer): 30–80 mm thickness

- Core and neck: alloy ductile iron, graphite steel, or forged steel to provide strength and toughness

- Transition layer: metallurgical bonding zone with controlled gradients of composition and hardness

Roll Shop Practice: Grinding and Maintenance of HSS Rolls

The performance of HSS rolls strongly depends on roll shop practice. Even the best roll material will not perform if roll grinding, roll handling, and surface preparation are inadequate.

Mill Roll Grinding and Roll Shop Parameters

HSS rolls require stable and precise grinding to maintain correct crown, taper, and surface finish. Key aspects include:

- Selecting grinding wheels suitable for hard HSS surfaces (e.g., alumina or CBN, depending on mill roll grinder design).

- Controlling grinding parameters (cutting speed, feed, coolant supply) to avoid surface burns and microcracks.

- Regularly inspecting roll surface by non-destructive testing (NDT) for cracks, spalling, and surface defects.

How to Clean Rolling Mill Rollers (Work Rolls and Backup Rolls)

Clean roll surfaces are essential for good strip quality. For HSS and steel mill rolls, cleaning procedures typically include:

- Mechanical cleaning: light buffing or brushing to remove adherent oxides and build-up.

- Chemical cleaning: using suitable alkaline or neutral solutions compatible with HSS microstructure to remove oil and dirt without attacking the oxide film.

- Filtration and control of rolling lubricants to minimize abrasive particles and sludge accumulation on the roll surface.

Roll shops must follow mill-specific cleaning procedures to avoid damaging the protective oxide film and to prevent corrosion when rolls are stored in the roll shop.

Wear and Failure Modes of HSS Rolls

Even though HSS rolls have high wear resistance, they are subject to various wear and damage mechanisms. Understanding these mechanisms helps mills and roll manufacturers optimize the rolling mill roll design and process conditions.

- Uniform wear: gradual reduction of barrel diameter; primarily abrasive wear by strip and scale.

- Non-uniform wear: edge build-up, center wear, dog-bone shape; often caused by insufficient or non-uniform cooling, misalignment, or inappropriate roll pass design.

- Thermal fatigue cracking (fire cracks): network of fine cracks due to cyclic heating and cooling; mitigated by homogeneous cooling and proper rolling practice.

- Spalling and shelling: local material break-out, often linked to sub-surface cracks or inclusion clusters; sensitive to accident conditions and microstructural defects.

- Mechanical damage: impact by cobbles, foreign bodies, or severe strip misalignment; must be minimized by careful mill operation and automation.

Regular monitoring of roll performance, measurement of wear profiles, and correlation with rolling data (force, temperature, speed, and cooling parameters) are necessary for continuous improvement and for optimal use of HSS rolls in demanding rolling mill environments.

Selection Guidelines for Mill Roll Materials in Practice

When selecting mill rolls for a given stand — whether hot mill rolls, cold mill rolls, forged rolls, or tungsten carbide rolls — the following practical criteria can be used:

- Rolling temperature and reduction: Higher temperatures and higher reductions favor HSS or tungsten carbide in finishing stands.

- Rolling speed: High-speed lines benefit from HSS rolls due to their superior thermal stability and wear resistance.

- Product type and surface quality: Thin strip and surface-critical products (automotive sheet, tin plate) often require HSS or tungsten carbide composite rolls in later stands.

- Accident risk: Roughing stands or stands prone to cobbles may rely more on forged steel rolls with higher toughness.

- Economics: While initial cost of HSS rolls is higher, total cost per ton of steel rolled often decreases because of longer life, fewer roll changes, and reduced grinding.

Cooperation among steel mills, mill roll manufacturers, and roll foundries is essential to define the correct combination of HSS, forged steel, high chrome cast iron, and tungsten carbide rolls for each stand in the rolling mill.

Practical Notes for Mill Roll Specialists and Manufacturers

For mill roll specialists, roll designers, and roll foundry engineers involved in production of steel mill work rolls and backup rolls, several points deserve attention:

- Control solidification and heat treatment to minimize segregation and to obtain uniform carbide distribution in the working layer.

- Optimize roll pass design and two-high / four-high / tandem rolling mill layout to take advantage of HSS wear characteristics.

- Adapt cooling system, nozzle distribution, and water flow for HSS rolls, as they react differently to thermal loads than conventional rolls.

- Provide detailed technical data to the user: rolling mill roll chemical composition, hardness profile, recommended grinding parameters, maximum allowable working temperature, and minimum residual diameter.

- Work closely with steel mills to monitor performance, analyze roll scrap, and progressively refine HSS roll grades for specific lines and products.

Conclusion

High-speed steel rolls combine high hardness, superior wear resistance, excellent heat resistance, good thermal conductivity, and uniform microstructure. In properly designed and well-operated rolling mills, HSS work rolls can provide more than three times the service life of alloy cast iron rolls, especially in hot and cold strip finishing stands.

To achieve this performance, it is essential to:

- Select appropriate HSS roll material and core material according to mill type and stand position.

- Design roll crowns, pass profiles, and cooling systems specifically for HSS behavior.

- Apply strict roll shop practices in grinding, inspection, and surface preparation.

- Monitor wear, thermal behavior, and damage to continuously adjust operating parameters.

When properly designed, manufactured, and used, HSS rolls provide a robust solution for reducing roll consumption, improving product quality, and increasing productivity in modern steel rolling mills.