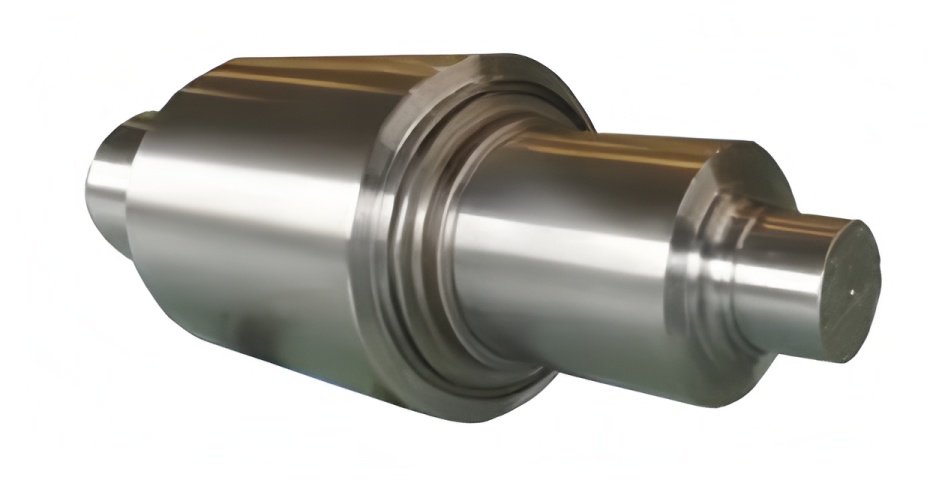

Forged backup roll for cold and hot strip mill – a critical component in modern rolling mill roll technology development.

In modern steel production, mill rolls are critical consumable components that directly determine rolling mill efficiency, rolled product quality, and overall production cost. From hot strip mills and plate mills to cold rolling mills and tube mills, every rolling mill relies on precisely engineered work rolls, backup rolls, and special-shaped rolls operating under extreme mechanical and thermal loads.

As product specifications become more stringent and rolling mills operate at higher speeds, traditional roll materials, surface treatments, and repair technologies are reaching their limits. This has accelerated the development of new mill roll technologies, particularly advanced surface engineering techniques such as laser cladding, which significantly improve roll hardness, wear resistance, and service life while reducing mill roll scrap and replacement frequency.

This article provides a comprehensive technical overview of new mill rolls technology development, focusing on:

- Types of rolls used in rolling mills and their functions

- Typical rolling mill roll materials and performance parameters

- Laser cladding technology for roll repair and surface strengthening

- Application cases for work rolls, backup rolls, and special-shaped rolls

- Selection and maintenance guidance for mill roll manufacturers and end users

Core keywords covered in this guide include: mill roll, rolling mill rolls, cold rolling mill rolls, hot rolling mill rolls, work rolls, backup rolls, forged rolls, tungsten carbide rolls, laser cladding of mill rolls, and rolling mill roll manufacturers.

What Are Mill Rolls in a Rolling Mill?

Mill rolls (also called rolling mill rolls or simply “rolls”) are rotating cylindrical components used in rolling mills to reduce the thickness, change the shape, and improve the surface of metal products such as strip, plate, bar, wire, and pipes. They transmit rolling force to the material and determine the geometry and surface finish of the rolled product.

In a typical rolling stand, rolls are mounted in chocks with bearings, supported by the roll housing, and driven by a main motor through spindles. Depending on the rolling mill type (two-high, four-high, six-high, twelve-high cluster mill, or tandem mill), one or more sets of rolls act simultaneously on the workpiece.

Mill roll meaning in production practice: they are high-value, high-load, precision components that:

- Bear enormous rolling forces (often > 10,000 kN in hot strip mills)

- Operate at elevated temperatures (up to 900–1100 °C in hot rolling)

- Endure cyclic contact fatigue and severe abrasive and adhesive wear

- Must maintain exact diameter, profile, and surface roughness

Types of Rolls Used in Rolling Mills

Rolling mills employ different types of rolls according to mill configuration and product type. Below is an engineering-oriented classification.

| Roll Type | Main Function | Typical Material | Typical Application |

|---|---|---|---|

| Work roll | Directly contacts and deforms the strip or bar; defines surface finish. | Forged steel, high chromium steel, tungsten carbide, composite roll. | Hot strip mills, cold rolling mills, bar and wire mills. |

| Backup roll | Supports work rolls to prevent bending; ensures shape control. | Forged steel with high toughness and contact fatigue strength. | 4‑hi/6‑hi/20‑hi cold mills, hot strip mills. |

| Intermediate roll | Used in 6‑hi and cluster mills; improves flatness and crown control. | Alloy steel with hardened surface. | 6‑hi cold rolling mills, high-precision strip rolling. |

| Forged roll | General term for rolls manufactured by forging for high strength. | Forged steel with controlled microstructure. | Hot and cold strip mills, plate mills, heavy section mills. |

| Cast roll | Rolls produced by casting; can be indefinite chill, high-chrome, etc. | Cast iron, high chromium cast iron, Adamite. | Roughing stands, section mills, finishing of long products. |

| Tungsten carbide roll | Provides extremely high wear resistance and stiffness. | Cemented carbide (WC–Co) monobloc or rings. | Wire rod mills, bar mills, skin-pass mills, high-speed finishing stands. |

| Special-shaped roll | Roll with complex profile for shape rolling and special sections. | Forged or cast steel with machined grooves/profiles. | Shape rolling, universal beams, rails, special profiles. |

Rolling Mill Roll Materials and Typical Properties

The choice of rolling mill roll material depends on mill type, rolling temperature, reduction schedule, lubrication conditions, and product requirements. Common materials include:

- Forged carbon and alloy steels

- High chromium steel and high-speed steel

- Cast iron rolls (indefinite chill, spheroidal graphite, etc.)

- Tungsten carbide rolls and composite rolls

| Roll Material | Hardness (HSD / HRC) | Typical Carbon Content | Key Features |

|---|---|---|---|

| Forged steel work roll (hot) | 32–46 HSD (approx. 32–42 HRC) | 0.4–0.8 % C | High toughness, good thermal shock resistance; used in hot strip and plate mills. |

| High-chrome steel work roll (cold) | 60–70 HSD (approx. 60–66 HRC) | 1.2–2.2 % C | High wear resistance, good surface quality; used for cold mill finishing stands. |

| Indefinite chill cast iron roll | 50–70 HSD | 2.5–3.5 % C | Good wear resistance, used in roughing and intermediate stands. |

| Tungsten carbide roll ring | 80–90 HRA (~70–80 HRC equiv.) | ≈6 % C in WC phase | Exceptional hardness and wear resistance; applied to high-speed wire, bar, and skin-pass mills. |

| Forged backup roll | > 30 HSD core, surface hardened | 0.5–0.8 % C | High load-bearing capacity, high contact fatigue strength, long campaign life. |

Values above are typical engineering ranges for industrial practice. Exact chemistry and hardness are optimized by each mill roll manufacturer according to rolling mill design and customer specifications.

Hot Rolling Mill Rolls vs Cold Rolling Mill Rolls

The difference between hot mill rolls and cold mill rolls is primarily determined by the rolling temperature, deformation mode, and surface quality requirements.

| Property | Hot Rolling Mill Rolls | Cold Rolling Mill Rolls |

|---|---|---|

| Rolling temperature | 800–1100 °C (hot steel) | Room temperature to < 200 °C |

| Main failure modes | Thermal fatigue, oxidation, fire-cracks, spalling, abrasion. | Wear, pitting, surface cracking, peeling, chatter marks. |

| Surface roughness (Ra) | Typically 1.0–3.0 µm (hot strip) | Typically 0.1–0.6 µm (cold strip) |

| Required hardness | Moderate to high, balanced with toughness | High to very high for wear resistance and surface quality |

| Typical materials | Forged steel, ICDP, high-chrome cast iron. | High-chrome steel, high-speed steel, tungsten carbide. |

For cold mill rolls, dimensional accuracy and surface finish of the strip are critical, especially for automotive, appliance, and tinplate applications. As a result, these rolls typically have higher hardness, more sophisticated heat treatment, and increasingly benefit from advanced surface technologies such as laser cladding, thermal spraying, and PVD coatings.

Wear of Hot Rolling Mill Rolls – An Overview

Wear of hot rolling mill rolls is a complex phenomenon influenced by temperature, contact pressure, roll material, lubrication, cooling, and oxide scale. Key mechanisms include:

- Abrasive wear due to hard oxide scale and inclusions between roll and strip

- Adhesive wear from micro-welding and tearing at high temperature

- Thermal fatigue caused by cyclic heating and cooling of the roll surface

- Mechanical fatigue from repeated rolling loads and bending moments

- Oxidation and decarburization of the roll surface

Industry practice shows that hot mill work rolls may lose several millimeters of diameter per campaign due to wear and fire-cracks. Consequently, frequent mill roll grinding is required to restore the profile and remove surface defects. Each grinding reduces roll diameter, and eventually the roll reaches its scrap size, generating substantial mill roll scrap.

To reduce roll consumption, mills have two main approaches:

- Optimize roll material, hardness, and cooling conditions to improve intrinsic wear resistance.

- Apply surface engineering technologies (e.g., laser cladding, high-speed steel overlays, carbide layers) to create a high-performance surface while retaining a tough core.

Laser Cladding: A New Generation Surface Technology for Mill Rolls

Laser cladding is an advanced surface treatment process that uses a high-power laser beam to melt feedstock material (usually powder or wire) and a thin layer of the substrate, forming a metallurgically bonded coating with low dilution. It offers precise control of:

- Cladding layer thickness (typically 0.5–4.0 mm on rolls)

- Chemical composition and microstructure

- Geometry, flatness, and surface finish

Compared with conventional surfacing (arc welding) or electroplating, laser cladding for mill rolls offers:

- Higher hardness – typical 55–65 HRC or more with carbide-reinforced alloys

- Superior wear resistance – particularly under abrasive and adhesive conditions

- Lower heat input – reduced distortion and smaller heat-affected zone (HAZ)

- Precise layer thickness – important for maintaining roll diameter and crown

- Metallurgical bonding – stronger than mechanical bonding of sprayed coatings

On steel mill rolls, laser cladding is mainly used for:

- Repair of worn work rolls and backup rolls to avoid scrapping high-value forged rolls

- Surface strengthening of new rolls to extend service life and reduce roll consumption

- Precision repair of special-shaped mill rolls with complex geometry

Steel Work Rolls: Repair and Surface Strengthening by Laser Cladding

Work rolls are the rolls that directly contact the strip and therefore dictate surface quality, thickness tolerances, and shape. For both hot work rolls and cold mill work rolls, laser cladding is increasingly adopted to:

- Restore diameter and profile of worn rolls

- Improve surface hardness and wear resistance

- Enhance resistance to corrosion, pitting, and thermal fatigue

By selecting suitable cladding alloys (e.g., high-chrome, high-speed steel, or carbide-reinforced systems), mills can tailor the surface for specific applications:

| Application | Recommended Cladding Layer | Typical Hardness | Key Benefit |

|---|---|---|---|

| Hot strip mill work roll | High-chrome steel or HSS laser cladding, 2–3 mm thickness. | 50–60 HRC | Reduced wear and fire-cracks, longer rolling campaigns. |

| Cold rolling mill work roll (finishing stand) | High-chrome / HSS with carbide dispersion. | 60–65 HRC | Improved surface quality, low roughness, extended roll life. |

| Skin-pass work roll | Carbide-rich overlay with corrosion resistance. | 62–67 HRC | Stable roughness, minimal wear during light reduction passes. |

In one documented case, a rolling mill applied laser cladding strengthening to cold mill work rolls and achieved more than 50 % reduction in surface roughness of rolled steel products, leading to a significant improvement in surface quality and rejection rates.

Repair and Strengthening of Backup Rolls

Backup rolls (also called backup rollers) are large-diameter forged rolls that support work rolls in multi-high mills. They endure enormous contact stress and cyclic fatigue and are critical for:

- Maintaining roll gap stability

- Controlling strip shape and crown

- Ensuring consistent contact between work roll and strip

Backup rolls are prone to:

- Surface wear and indentation

- Subsurface rolling contact fatigue (RCF) and spalling

- Cracking near the barrel surface due to high Hertzian stress

Using laser cladding to repair and strengthen backup rolls allows mills to create a high-strength, highly wear-resistant layer on the roll surface without compromising the tough forged core. Typical cladding thickness is 1.5–3.0 mm, with hardness between 45–60 HRC depending on application.

A practical example from HANI shows that after applying laser cladding to cold and hot strip mill backup rolls, the service life increased by more than two times, significantly reducing roll consumption and overall rolling mill operating cost.

For steel plants evaluating forged backup roll maintenance strategies, the combination of laser cladding and optimized backup roll grinding produces a high-value life-cycle extension, especially for large backup rolls with long production lead times and high purchase prices.

Repair of Special-Shaped Mill Rolls by Laser Cladding

Special-shaped rolls, used for shape rolling of beams, rails, channels, and various profiles, often have complex grooves and contours. Traditional repair methods (such as manual welding and heavy machining) struggle to:

- Ensure homogeneous hardness and microstructure in intricate grooves

- Maintain the original profile tolerance without excessive machining allowance

- Control heat input and distortion during welding

Laser cladding solves these problems by accurately depositing material along the required contours with:

- Small heat-affected zones

- High positional accuracy

- Flexibility to use different alloys in different regions if needed

In one case, a steel mill used laser cladding to repair worn special-shaped rolls. After finishing, the rolls achieved restored dimensional accuracy and surface quality fully meeting production requirements, while saving substantial costs and time compared with manufacturing new rolls.

Tungsten Carbide Rolls and Composite Roll Technologies

Tungsten carbide rolls and tungsten carbide roller rings are widely used where extremely high wear resistance and dimensional stability are required, such as high-speed bar and wire mills, reduction stands, and skin-pass mills.

Tungsten carbide (WC) is typically combined with cobalt or nickel as a binder, forming cemented carbide. Compared with steel rolls, tungsten carbide rolls provide:

- Very high hardness (80–90 HRA)

- High modulus of elasticity – less deflection under load

- Excellent wear resistance in dry and lubricated rolling

For cost and toughness reasons, mills often use tungsten carbide composite rolls, where a tungsten carbide ring is mounted on a steel arbor. These are especially common in:

- Wire rod finishing blocks

- Bar mill sizing stands

- Precision tube mills and certain cold rolling applications

For mills sourcing from Asia, tungsten carbide rolls manufacturers in India supply a wide range of carbide roller rings and composite rolls. Quality evaluation should focus on carbide grain size, binder content, ring density, and real hardness measurements. When assessing authenticity (how to tell if tungsten carbide is real), density, hardness tests, and spark tests under grinding are useful indicators.

Forged Rolls, Roll Forging, and Mill Roll Manufacturing

The majority of high-performance steel mill rolls for hot and cold strip, plate, and heavy sections are produced as forged rolls. Forging refines the microstructure, closes internal defects, and improves toughness and fatigue strength compared with cast rolls.

What is roll forging? In general metallurgy, roll forging refers to a forming process where a round or flat bar is passed through rotating rolls with a shaped groove to reduce cross-section and improve mechanical properties. In the context of mill rolls, “forged rolls” usually means large ingots of high-quality steel are forged under a press or hammer to achieve the desired shape and properties before machining and heat treatment.

Typical forged steel rolls and forged steel work rolls:

- Forged at high temperatures to refine grains (target grain size often 4–7, ASTM)

- Heat treated (quenching and tempering) for uniform hardness

- Bored and ultrasonically tested to detect internal flaws

Internationally, there are forged rolls manufacturers in many countries. References in trade data include forged steel work rolls exporters in India, South Africa, Vietnam, and Tanzania. When selecting suppliers, parameters such as residual stress control, ultrasonic testing level (UT standard), and chemical composition tolerances are as important as nominal hardness.

Rolling Mill Types and Roll Arrangements

Understanding rolling mill types helps define the role and performance requirements of each roll. Major configurations include:

- Two-high rolling mill – two opposing rolls; used for heavy breakdown rolling.

- Three-high rolling mill – three rolls; strip is passed alternately in opposite directions.

- Four-high rolling mill (4‑hi) – small work rolls supported by larger backup rolls; common in strip mills.

- Six-high and twenty-high mills – include intermediate rolls and multiple backup rolls for thin, high-precision strip.

- Tandem rolling mill – several stands in series, enabling high reductions in a single pass line.

In all these configurations, work rolls and backup rolls form the core rolling elements; their material, hardness, and surface condition must be adapted to each stand’s function and reduction schedule.

Practical Parameters for Work Roll and Backup Roll Selection

Steel mills and rolling mill roll manufacturers typically define roll specifications with a set of engineering parameters. The table below summarizes common ranges for reference. Exact values depend on mill design and product mix.

| Roll Type | Roll Diameter Range | Barrel Length Range | Hardness Range | Typical Application |

|---|---|---|---|---|

| Hot strip mill work roll | 600–900 mm | 1500–2500 mm | 32–50 HSD | Finishing and roughing stands in hot strip mills. |

| Cold mill work roll (4‑hi) | 300–650 mm | 800–2200 mm | 60–70 HSD | Cold reduction of strip and sheet steels. |

| Backup roll (hot/cold) | 800–1800 mm | 1500–3000 mm | 30–45 HSD | Support work rolls in 4‑hi and 6‑hi mills. |

| Wire rod tungsten carbide ring | 80–400 mm (outer) | Width 50–300 mm | 80–90 HRA | Finishing blocks of wire and bar mills. |

Roll Shop Practices: Grinding, Cleaning, and Maintenance

A well-organized roll shop is essential for maintaining the performance of work rolls and backup rolls. Key activities include:

- Mill roll grinding – restoring crown, profile, and surface roughness.

- Inspection – checking for cracks, spalling, and residual defects using NDT.

- Balancing – ensuring rolls meet dynamic balance requirements.

How to Clean Rolling Mill Rollers

Clean roll surfaces are essential for avoiding surface defects. Basic principles for how to clean rolling mill rollers include:

- Use non-abrasive solvents or compatible detergents to remove oil, coolant residue, and rust inhibitors.

- Avoid coarse abrasive paper directly on the roll surface; use fine polishing if absolutely necessary.

- Ensure roll surfaces are completely dry before storage; apply a thin rust-preventive oil film.

- For carbide and laser-clad surfaces, follow manufacturer guidelines to avoid micro-cracking or delamination.

In high-capacity steel mills, specialized steel mill roll grinders and automated roll turning machines are used to minimize human error and achieve consistent roll quality.

Mill Roll HS Code, Scrap Management, and Logistics

For international trade, mill roll HS code (or HSN code) usually falls under the heading for “Rolls for rolling mills”. Many countries use a code within HS 8455 for rolling mill machinery and HS 8455.30 or similar for rolls. Exact classification may vary slightly by customs authority, so it is advisable to confirm with local regulations.

Work roll HSN code and backup roll HSN code are typically the same category as rolling mill rolls. Correct HS classification is crucial for import duties, export documentation, and tariff negotiations.

Regarding mill roll scrap, worn-out or broken rolls are often recycled as high-grade alloy steel scrap. Tracking the ratio of roll consumption to rolled tonnage (kg/ton) is a key KPI for steel mills, and modern laser cladding technologies are directly aimed at reducing this number by extending roll life.

Laser Cladding and Mill Roll Technology – Video Reference

Rolling Process Fundamentals and Roll Mechanics (Brief Overview)

The rolling process is governed by contact mechanics, plastic deformation, friction, and thermal conditions. From a mechanical point of view:

- Rolls are subjected to bending, shear, and compressive forces.

- Roll deflection affects strip crown and flatness.

- Roll surface roughness influences friction and lubrication regimes.

Engineering calculations for roll torque, separating force, and roll flattening are often introduced in mechanics of rolling and rolling process handbooks (commonly provided as cold rolling mill process PDFs or rolling process PDFs). These are used during roll design, selection of roll material, and evaluation of rolling mill roll design including crown and chamfer geometry.

Practical Considerations When Working with Mill Roll Manufacturers

When selecting mill roll manufacturers or a mill roll specialist, steel plants should evaluate:

- Experience with similar rolling mills (hot strip, tandem cold mill, bar mill, tube mill, etc.).

- Ability to produce rolling mill rolls chemical composition certificates with tight tolerances.

- In-house roll foundry or forging capabilities and heat treatment facilities.

- Laser cladding, grinding, and rolling mill roll assembly service capability.

- References from other steel mills or steel rolling mill roll manufacturers with similar product ranges.

In markets like India, rolling mill rolls manufacturers in India provide a broad spectrum from cast iron flour mill rolls to high-end forged steel work rolls and tungsten carbide composite rolls. Global names (including Deem Roll Tech Ltd, Shah Forged Rolls, etc.) have expanded their export presence, supplying rolls to Asia, Africa, and Europe.

Tube Mill Rolls and Flour Mill Rolls – Special Cases

While this article focuses mainly on steel rolling mills, similar principles apply to:

- Tube mill rolls – used for forming, welding, and sizing tubes and pipes. Surface hardness and precision of tube mill rolls greatly affect weld quality and roundness.

- Flour mill rolls – typically cast iron rolls used for grinding grain. The flour mill roll body requires controlled hardness and surface fluting, but operates under much lower temperatures and mechanical loads than steel mill rolls.

In both sectors, roll material, surface treatment, and maintenance have a direct influence on product quality and process efficiency.

Outlook: New Mill Rolls Technology Development

The development of new mill rolls technology is driven by higher expectations for productivity, strip quality, and cost efficiency in the steel industry. Traditional technologies alone can no longer meet the requirements of ultra-thin, ultra-clean, and high-strength steels.

Advanced solutions such as laser cladding, tungsten carbide composite rolls, and optimized forged steel roll designs now play a central role in:

- Extending work roll and backup roll life

- Reducing roll consumption per ton of rolled product

- Improving thickness control, shape control, and surface finish

- Lowering total cost of ownership of rolling mill equipment

For mill operators and engineers, cooperation with competent rolling mill roll manufacturers and mill roll specialists, combined with adoption of new surface technologies like laser cladding, will be decisive in achieving long-term competitiveness and sustainable production in hot and cold rolling mills.